Product Info: Linear Actuator

Tsubaki's linear actuator include a lineup of electric cylinders and jacks that use high-quality screws manufactured in-house, as well as our proprietary Zip Chain Zip Chain Actuator.

Both the screw mechanism and Zip Chain mechanism make the most of the product's features and can be used for a wide range of applications, including high-speed, high-frequency operation and operation requiring high precision.

* Zip Chain mechanism is our proprietary technology in which two chains interlock like a zipper to form a single, strong pillar that can be used for both pushing and pulling.

Table of contents

linear actuator related information

-

Selection

-

Materials

-

Operation

Linear motion mechanism type

Zip Chain Mechanism

- High speed

- High frequency

- High durability

- compact

This mechanism uses Tsubaki's proprietary technology, "Zip Chain."

It is highly compact and has the high speed, high frequency and durability required for high tact operation.

By interlocking two chains together to form one rod, it is possible to push and pull.

It was named Zip Chain because it interlocks like a zipper.

(Click here for the special website for the Zip Chain mechanism)

Ball screw mechanism/ Trapezoidal Screw mechanism

- High frequency

- Maximum allowable load

- Quietness

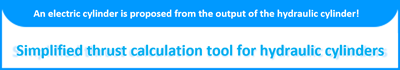

Ball screw mechanism

This mechanism uses steel balls placed between the screw shaft and nut to create rolling friction, allowing for highly efficient operation.

Compared to Trapezoidal Screw mechanisms, it is suitable for high-speed, high-frequency applications, making it suitable for assembly lines where productivity is required.

In addition, its high efficiency allows the drive source to be made smaller.

As we use highly reliable Ball screw manufactured in-house, it is possible to predict the running life.

Ball screw screw with a longer lead per rotation than a regular Ball screw is called a high-lead Ball screw, and can achieve higher speeds even with the same input rotation speed as a regular Ball screw.

Trapezoidal Screw mechanism

This mechanism works by the sliding friction between the screw shaft and nut, and is suitable for low-speed, low-frequency operation such as for maintenance purposes.

It has a self-locking property that Ball screw mechanisms do not have, making it possible to hold loads.

In addition, its simple structure makes it economical.

Tsubaki's linear actuator Product Line

| Electric cylinder: Power Cylinder | Screw jack: Linipower Jack |

Ball screw lifting unit: Linispeed Jack |

Interlocking chain actuator: Zip Chain Actuator |

||

|---|---|---|---|---|---|

|

|

|

|

||

| Mechanism Type | Ball screw Trapezoidal Screw |

Ball screw High Lead Ball screw |

Trapezoidal Screw | Ball screw | Zip Chain |

| the purpose | Pushing and pulling loads | Pushing and pulling loads | Load retention | Pushing and pulling loads | Pushing and pulling loads |

| Features | Motor integrated for easy wiring Realizing a clean environment |

Various screw types available | High Speed/High Frequency, Low Profile, Long Life | High speed and frequency that surpasses other mechanisms, Low profile, long life |

|

| Thrust | Max 490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| Stroke | Maximum 2000mm | Maximum 2000mm | Maximum 1500mm | Maximum 2000mm | |

| Speed and Operating Frequency | Maximum speed: 333mm/s Percentage duty cycle: 50%ED *1 |

Maximum screw shaft speed: 50 to 120 mm/s *2 Allowable Percentage duty cycle: 30%ED |

Maximum screw shaft speed: 40mm/s Allowable Percentage duty cycle: 20%ED |

Maximum screw shaft speed: 200mm/s Allowable Percentage duty cycle: 100%ED *3 |

Maximum speed: 1000mm/s Percentage duty cycle: 100%ED |

| Application example |

Tilting device

Stopper |

Table lift

Rolling Mill |

traverser 's

Take-out |

Stacking and unstacking

Pallet |

|

- *1 Eco series servo type

- *2 Varies depending on screw type

- *3 Varies depending on conditions.

Linear Actuator Product List

This is an electric cylinder that can be used with just simple electrical wiring.

An electric cylinder is a linear motion mechanism that converts the rotation of a prime mover into thrust using a mechanism that combines Trapezoidal Screw or Ball screw and nut, moving a rod back and forth. It is primarily used to push and pull loads.

Compared to the widely used hydraulic and pneumatic cylinders, electric cylinders offer many advantages in terms of energy efficiency, ease of handling, and maintainability.

(Reference information: Benefits of replacing hydraulic and pneumatic systems)

Tsubaki's Power Cylinders feature a compact design, high-speed operation, and excellent durability, greatly contributing to improved equipment productivity. Furthermore, the integrated motor simplifies electrical wiring and reduces installation labor. Tsubaki's Power Cylinder, created using manufacturing technologies honed over more than half a century, demonstrate their capabilities in a wide range of industries and applications, including infrastructure, IT/semiconductor equipment, steel equipment, port equipment, environmental equipment, various inspection equipment, and automobile manufacturing equipment.

Application example

| Opening and closing | Lifting | Invert | Stopper | handling | Positioning |

|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

U Series

Model number LPUB~/LPUC~

The "Power Cylinder U Series" is a compact and lightweight electric cylinder with a rated thrust of over 6 tons.

(Large thrust 58.8kN or more)

- ・Lightweight and compact:

The newly developed high-performance Ball screw and strengthened bearings have reduced the overall length by up to 10% compared to the conventional product (T series).

We have succeeded in reducing the mass by 35%. The compact and lightweight design makes it easy to replace hydraulic cylinders. - ・Full lineup:

The rated thrust of 50 tons has been expanded, making it easier to replace hydraulic cylinders with inner diameter of Φ250 mm class. - ・Improved cost performance:

The parts have been made smaller and lighter, resulting in lower costs compared to conventional products. In addition, the electric system is more economical than hydraulic systems.

It has a great energy saving effect and significantly reduces power consumption.

Rated thrust kN

58.8~490

Speed mm/s

50Hz:6.5~43

60Hz:7.8~52

Stroke mm

500~2000

U Series Multi-Specification

Model number LPUA□□□□B~ LPUC□□□□B~

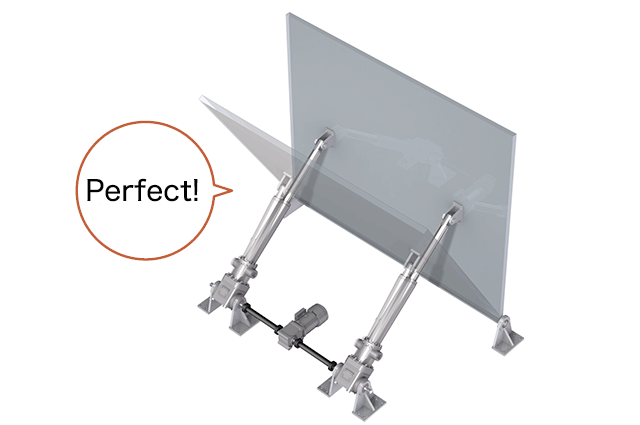

This electric cylinder can perfectly synchronize multiple cylinders with one motor. (High thrust of 58.8kN or more)

- ・High speed support:

High speed operation of up to 150mm/s is available as a special model. - - Safety:

A thrust detection mechanism that detects and protects against overload can be built in. (LPUC) - ・Tough construction:

The operating section that supports the load and the reduction section are separated. There is no change in gear tooth contact due to fluctuating load. - ・Multiple units can be linked:

By using an input shaft with sufficient strength, multiple units can be linked together. - ・Swing operation possible:

The input shaft and trunnion section have the same axis, so they can oscillate while operating in tandem.

Allowable thrust kN

58.8~313

Speed mm/s

50Hz:6.5~43

60Hz:7.8~52

Stroke mm

500~2000

T Series

Model number LPTB~/LPTC~

This is an electric cylinder in the medium thrust zone that can be used with AC power (medium thrust 39.2kN or less).

- - Two safety mechanisms:

You can choose the type based on the protection method. The TB type has a built-in wet slip clutch. The TC type has a thrust detection limit switch. - ・Wide variation:

We offer a wide range of standard models to suit your application, thrust, and speed.

Thrust is available from 2.45kN to 39.2kN, and speed is available from 9mm/s to 120mm/s. - ・Reliable operation:

It has a highly reliable built-in safety device that works effectively against overload. - - Wide range of options:

There are two types of stroke adjustment limit switches available: external and internal, and two types of stroke sensors available: potentiometer and rotary encoder.

Rated thrust kN

2.45~39.2

Speed mm/s

50Hz:9~100

60Hz:11~120

Stroke mm

200~1500

T series multi-specification

Model number LPTB□□□□B~ LPTC□□□□B~

It is ideal for synchronously operating multiple cylinders with one motor. (Medium thrust 39.2kN or less)

- ·safety:

Thrust detection limit switch that detects and protects against overload can be built in. (LPTC) - ・Tough construction:

The operating section that supports the load and the reduction section are separated. There is no change in gear tooth contact due to fluctuating load. - ・Multiple units can be linked:

By using an input shaft with sufficient strength, multiple units can be linked together. - ・Swing operation possible:

The input shaft and trunnion section have the same axis, so they can oscillate while operating in tandem.

Allowable thrust kN

4.94~39.2

Speed mm/s

72~120

Stroke mm

200~1500

Worm Series

Model number LPWB~

The worm series is an electric cylinder that is ideal for replacing hydraulic cylinders.

- - High thrust is achieved by adopting high-precision worm gears that utilize Tsubaki's long-cultivated technology and high-efficiency ball screws.

- ·clean:

Since there are no hydraulic pumps or piping, there is no need to worry about oil leaks from joints. - Easy to install:

No hydraulic pump or piping is required. It can be operated simply by connecting to a three-phase power source. - ・Precise control:

Using an inverter, etc., it is possible to change the speed and perform accurate positioning. - ・Low cost:

The number of parts has been significantly reduced, resulting in lower costs. - ・High load capacity:

By using a special steel alloy, it can handle heavy loads just like a jack.

Rated thrust kN

49~490

Speed mm/s

5 to 72 (reference value)

Stroke mm

200 to 2000 (reference value)

G Series

Model number LPG~

This is an electric cylinder in the small thrust zone that can be used with AC (alternating current) power sources. (Thrust of 3.00 kN or less)

- ・Wide variation:

There are 630 basic models, and when adding models equipped with options, there are approximately 9,000 standard models. - ・Stable, high efficiency and long life:

By using a specially designed centralizing Trapezoidal Screw and a nut material that is highly compatible with it, we have achieved stable, high efficiency and a long life. - ・You can select the type of screw to suit your application:

Basically, Trapezoidal Screw is used. If you want to use it for high-speed, high-frequency operation, please consider using Ball screw type. - ・Quiet operation:

The quiet DC brake motor drive significantly reduces noise during start-up and stop. - ・Excellent speed stability:

It is possible to operate at a stable speed without being affected by load fluctuations.

Rated thrust N

700~3.00k

Speed mm/s

50Hz:25~200

60Hz:30~240

Stroke mm

100~1200

F Series

Model number LPF~

This is a small thrust type electric cylinder that is powered by DC (battery) power.

- ・Compact and lightweight, making effective use of installation space:

It is a compact design with the actuator and motor arranged at right angles. The clevis bracket is open in two perpendicular directions, so you can choose from four installation directions to avoid interference with the mating machine. - ・Can be used outdoors:

Ideal for outdoor use such as agricultural machinery and multi-storey car parks. - - Wide range of options:

A wide range of options are available, including position detection units and overload detection units.

Rated thrust N

100~6.00k

Speed mm/s

8~54

Stroke mm

50~600

Eco Series Servo Type

Model number LPES~

It is capable of high-speed, high-precision operation to maximize the performance of the servo motor.

- ・Maximize servo motor performance:

The combination of a highly efficient Ball screw and a highly rigid, lightweight disc coupling maximizes the performance of the servo motor. - ・High stopping accuracy:

High-precision Ball screw are used to achieve high stopping accuracy, with repeatable positioning accuracy of ±0.02 mm and stopping accuracy of within ±0.1 mm. - ・Advantages of the precision planetary reducer:

By reducing the size of the servo motor, the peripheral devices can also be made smaller, which not only reduces the initial costs but also reduces the amount of power required, resulting in reduced running costs. - ・Servo motor can be selected:

We can install the servo motor of your choice. Please inform us of the servo motor manufacturer or mounting code when requesting a quote. - ・Achieves high speed and a wide range of thrust:

It can be used at high speeds and with large thrust.

Rated thrust N

150~15.0k

Speed mm/s

1~333

Stroke mm

300~1000

Eco Series CDS Type

Model number LPE~

Ideal for use in two-point operation such as air cylinders. Comes with a current detection type self-contained function.

- ・Self-contained:

The spring built into the actuator and the CDS (Current Detective System) installed inside the terminal box press the

When stopped or in the unlikely event of an overload, it detects overcurrent and automatically stops the motor.

When stopped, Pressing force is maintained by the built-in spring. - ・Reduced running costs and environmental friendliness:

Because it is electrically operated, it consumes electricity only when in use, making it economical. There is no need to run the compressor all the time like with air systems, which allows for significant reductions in running costs. - ・High frequency operation and long life:

High frequency operation of up to 15 times per minute is possible. In addition, the use of Ball screw can be expected to have a long life of 1 million strokes. - ・Easy to use:

It can be operated simply by connecting a three-phase power supply. There is no need for a limit switch for stroke adjustment, so there is no need for complicated wiring. Long wiring distances are also OK.

Rated thrust N

250~1.00k

Speed mm/s

200V 50Hz:90~160

200V 60Hz:90~190

220V 60Hz:110~200

Stroke mm

100~600

Mini series

Model number LP~

This series is suitable for automating small everyday applications of force.

It can serve as your arm.

- ・Single-phase power supply is OK

- ・Long life design

- ・Abundant options

Rated thrust N

98.0~392

Speed mm/s

50Hz:9~34

60Hz:11~42

Stroke mm

100~300

Please also refer to the following documents for information on how to use each series.

Benefits of replacing hydraulic/pneumatic cylinders with electric cylinders (Power Cylinder)

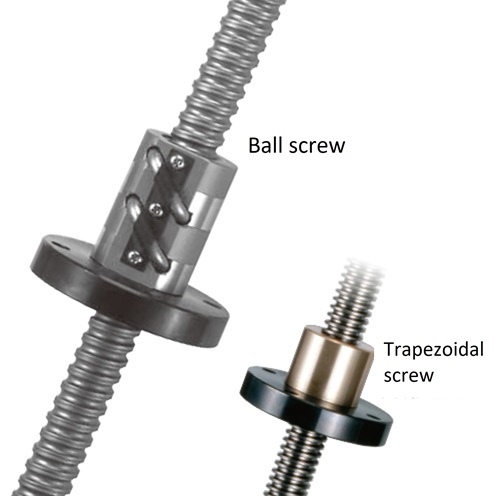

Energy saving and cost performance

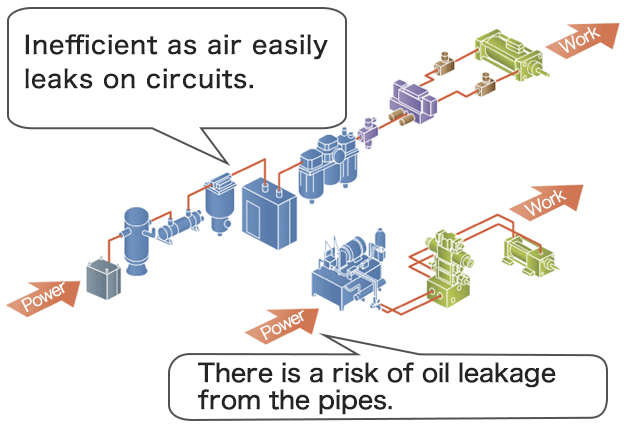

Hydraulic and pneumatic cylinders are widely used,

・ Pumps and compressors must be run longer than they are actually in operation

・ The system is complex and inefficient

For these reasons, electricity consumption tends to increase.

On the other hand, Power Cylinders

・ Consumes power only when in operation

・ The system is simple and efficient

Therefore, there is a big difference in power consumption even when the same amount of work is being done.

Improved installation and maintenance

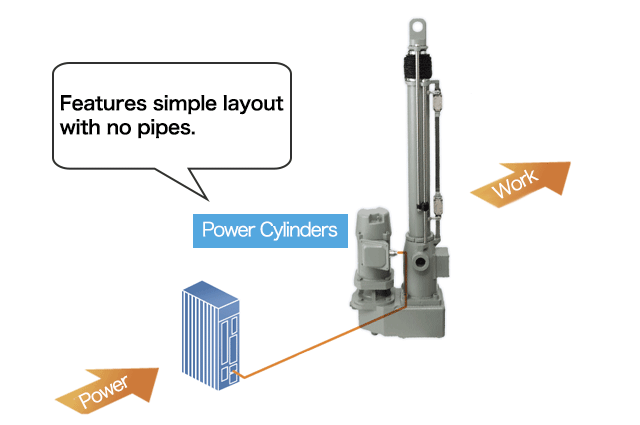

Electrification simplifies the system configuration, making installation easier.

The only drive source is a cable connection. There is no need for the piping and pumps required for hydraulic and pneumatic cylinders, and there is no need to worry about oil leaks from the main body or piping.

In addition, there is no need for periodic oil changes, which are required with hydraulic cylinders, or removal of sludge (deposits) that accumulate in the piping, so maintenance costs and labor can be significantly reduced.

Hydraulic and pneumatic cylinders have complex system configurations

Power Cylinders have a simple system configuration

Improved controllability and safety

In hydraulic and pneumatic systems, the surrounding temperature affects thrust. In particular, in hydraulic systems, the viscosity of the oil is affected by the surrounding temperature, which affects thrust, so proper oil temperature management is necessary.

In addition, the operating speed changes depending on the load, so it is difficult to maintain a constant speed and thrust regardless of temperature or load.

On the other hand, Power Cylinders can always obtain stable thrust and speed.

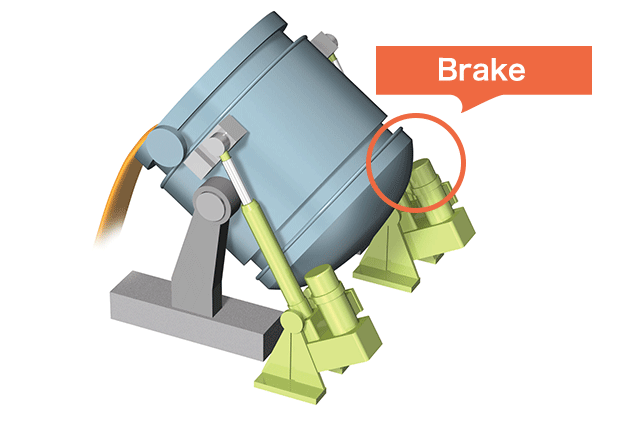

It can operate at a constant speed regardless of the installation direction or operating direction. In addition, since the motor has a brake, there is no need to supply electricity while holding the load, so there is no need to worry about falling accidents during power outages.

Power Cylinders provide stable speed regardless of load conditions

Brakes can be used to hold the load at the stopped position

Guide to replacing hydraulic cylinders with electric cylinders (Power Cylinder)

Click here for a tool that calculates the thrust from the hydraulic cylinder you are currently using and narrows down the compatible Power Cylinder models

Quick reference table of hydraulic cylinder specifications and Power Cylinder compatible models

| Cylinder Inner Diameter mm |

Piston Rod Diameter mm |

Operating pressure | |||

|---|---|---|---|---|---|

| 7MPa | 10MPa | 14MPa | 21MPa | ||

| 100 | 56 | LPT4000 | LPT4000 | LPU6000 | LPU8000 |

| 125 | 70 | LPT4000 | LPU6000 | LPU8000 | LPU12000 |

| 140 | 80 | LPU6000 | LPU8000 | LPU12000 | LPU16000 |

| 160 | 90 | LPU6000 | LPU12000 | LPU12000 | LPU22000 |

| 180 | 100 | LPU8000 | LPU12000 | LPU16000 | LPU32000 |

| 200 | 110 | LPU12000 | LPU16000 | LPU22000 | LPU32000 |

| 224 | 125 | LPU12000 | LPU16000 | LPU32000 | LPU50000 |

| 250 | 140 | LPU16000 | LPU22000 | LPU32000 | LPU50000 |