Power Cylinder G Series

- This is an electric cylinder in the small thrust zone with a rated thrust of 700N or more that can be used with AC (alternating current) power.

The type of screw can be selected according to the application. - With improved performance and an expanded range of options, we have standardized 9,000 models, the largest in this class, allowing you to select the optimum model for any application or device.

- *CCC certified products are available for quick delivery.

- Rated thrust: 700N to 3.00kN

- Nominal speed: 25-120mm/s

Features

-

・Wide variation

We have standardized 630 basic models, and approximately 9,000 models including models equipped with options.

-

- Stable, high efficiency and long life

By using a nut material that is highly compatible with the centralizing Trapezoidal Screw designed specifically for Power Cylinder, stable, high efficiency and a long life have been achieved.

Power Cylinder G Series basically uses Trapezoidal Screw. If you wish to use it for high-speed, high-frequency operation, please consider Ball screw type.

-

・Quiet operation

The silent DC brake motor drive significantly reduces noise during start-up and stop.

-

・Excellent speed stability

The basic structure is that an induction motor rotates the screw shaft and moves the nut (rod) forward and backward, so it is less susceptible to load fluctuations and can operate at a stable speed.

-

・CCC certified products, all sizes available with Quick delivery

To export small-output electric motors of 1.1kW or less to China, they must display the CCC mark, which certifies compulsory certification.

All sizes of the G series are CCC certified and can be delivered in a Quick delivery (standard delivery is 14 days).

How to use each type (protective device) and its structure

-

・Type A (without overload protection mechanism)

The motor brake stops the motor. Please note that exceeding the minimum and maximum nominal stroke dimensions may cause damage.

When using this type, be sure to install a sensor or other device to regulate the stroke yourself, or use our optional external stroke adjustment LS.

-

・B type (Wet-type slip clutch)

Wet-type slip clutch is built into the screw shaft end of the reduction section. A special lining is used to provide protection in the event of an overload.

The special lining provides protection even during overstroke.

-

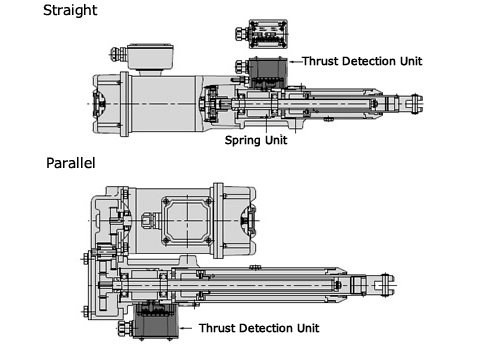

・C type (Thrust detection limit switch)

The bracket has a built-in thrust detection spring unit, which is effective when an electrical signal is required for push (pull) stop or overload.

An electrical signal is also output if an overload occurs from the load side while the motor is stopped or if the stroke is exceeded.

*In particular, when subjected to impact, the built-in spring will deflect and absorb the impact load.

Standard model list

| Model number | Rated thrust N {kgf} |

Nominal speed 50/60Hz mm/s |

Motor Capacity kW |

Nominal stroke mm |

|

|---|---|---|---|---|---|

| LPGA070 LPGB070 LPGC070 |

L | 700 {71.4} |

25/30 | 0.1 | 100 200 300 400 500 600 800 1000 1200 |

| M | 75/90 | 0.2 | |||

| H | 100/120 | 0.4 | |||

| U | 200/240 | 0.4 | |||

| LPGA100 LPGB100 LPGC100 |

L | 1.00k{102} | 25/30 | 0.1 | |

| M | 75/90 | 0.2 | |||

| H | 100/120 | 0.4 | |||

| U | 200/240 | 0.4 | |||

| LPGA150 LPGB150 LPGC150 |

L | 1.50k{153} | 25/30 | 0.2 | |

| M | 75/90 | 0.4 | |||

| H | 100/120 | 0.4 | |||

| LPGA300 LPGB300 LPGC300 |

L | 3.00k{306} | 25/30 | 0.4 | |

| M | 50/60 | 0.2 | |||

| H | 67/80 | 0.4 | |||

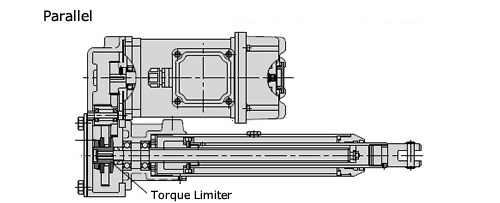

- *The LPGB type is only available in parallel due to its mechanism.

- *U-speed push stop cannot be used with the LPGC type.

- *The motor capacity for the H speed of LPGC070 and LPGC100 is 0.2kW.

Catalogs and Instruction Manuals

Motor Specifications

| Model | Fully sealed and air cooling type with brake | |

|---|---|---|

| output | See the list of standard models | |

| Number of poles | 4 poles | |

| power supply | Voltage | 200V/200V/220V |

| frequency | 50Hz/60Hz/60Hz | |

| Time rating | 30 minute rating | |

| Heat resistance class | B | |

| protective structure | Fully sealed outdoor model (IP55) | |

Model number display example

| LPG | C | 300 | L | T | 5 |

| | Series Name Power Cylinder G Series |

| | | | | | | |

| Rated thrust 070: 700N{71.4kgf} 100: 1.00kN {102kgf} 150: 1.50kN {153kgf} 300: 3.00kN {306kgf} |

| | | | | | | |

| Body shape T: Straight K: Parallel |

| Nominal stroke 1: 100mm 2: 200mm 3: 300mm 4: 400mm 5: 500mm 6: 600mm 8: 800mm 10: 1000mm 12: 1200mm |

| type A: No overload protection mechanism B: Wet-type slip clutch C: With Thrust detection limit switch |

Nominal speed L, M, H, U Please refer to the detailed information for actual speeds. |

||||

■ Tsubaki model No. navigation

Type

A: This is the basic type without any protective devices.

B: Torque Limiter is built in as an overload protection device. This is available only with the parallel type.

C: Equipped with Thrust detection limit switch.

Rated thrust

This is the rated thrust at which the motor can operate.

Nominal speed

This is the cylinder operating speed when the motor is rotating synchronously.

Please refer to the detailed information for the speed values of each model.

Body shape

T: A straight shape in which the motor and actuator are arranged in a straight line.

K: A parallel configuration with a gearbox placed between the motor and actuator.

Nominal stroke

The stroke distance of the operating part.

Motor Specifications

Z: Inverter drive compatible.

V: The power supply voltage and frequency are 400/400/440V, 50/60/60Hz.

V1: The power supply voltage and frequency are 380V and 50Hz.

V2: The power supply voltage and frequency are 380V, 60Hz.

V3: The power supply voltage and frequency are 415V, 50Hz.

V4: The power supply voltage and frequency are 460V, 60Hz.

T1: Heat resistance class F, resistant to 40°C.

T2: Heat resistance class F, 60°C.

T3: Heat resistance class F, 80°C.

T4: Heat resistance class H, 80°C resistant.

N: CE compliant.

N2: UL standard compliant specifications.

N3: CCC specification.

D: Pressure-resistant and explosion-proof.

A: It is an adapter without a motor.

Option symbol

M: The rod is fitted with a rotation stopper.

L: Comes with external stroke adjustment LS.

K2: Two built-in microswitches detect the stroke position.

Only parallel type is available.

K4: Equipped with four built-in microswitches that detect the stroke position.

Only parallel type is available.

P: Equipped with a potentiometer that detects the stroke position.

Only parallel type is available.

R: Equipped with a rotary encoder that outputs a stroke movement signal.

Only parallel type is available.

C: Equipped with clevis.

Only parallel type is available.

I: Equipped with I-type end fitting.

J: It comes with bellows.

*Various options are available.

Product model number list

*Click on the model number to display detailed information. Open all Close all

Thrust 700N {71.4kgf} (Model numbers LPGA070~, LPGB070~, LPGC070~)

Thrust 700N {71.4kgf} (Model numbers LPGA070~, LPGB070~, LPGC070~)

Thrust 1.00kN {102kgf} (Model numbers LPGA100~, LPGB100~, LPGC100~)

Thrust 1.00kN {102kgf} (Model numbers LPGA100~, LPGB100~, LPGC100~)

Thrust 1.50kN {153kgf} (Model numbers LPGA150~, LPGB150~, LPGC150~)

Thrust 1.50kN {153kgf} (Model numbers LPGA150~, LPGB150~, LPGC150~)

Thrust 3.00kN {306kgf} (Model numbers LPGA300~, LPGB300~, LPGC300~)

Thrust 3.00kN {306kgf} (Model numbers LPGA300~, LPGB300~, LPGC300~)

Special support

・Special support is available to suit your usage conditions.