Product Info Clutch

A mechanical element that transmits and blocks rotation between two power transmission shafts.

There are two types of lineup: cam clutches (one-way clutches) and SR clutches (single rotation clutches). Cam clutches have a mechanical non-backlash structure with many cams arranged between the inner and outer race, and are available for three different uses: backstop, overrunning, and indexing.

With a simple lever operation, the SR clutch can give a full rotation or an integer number of rotations from the continuously rotating outer race (drive side) to inner race (load side) with precise timing.

Table of contents

Clutch related information

-

Selection

-

Materials

What is a Cam Clutch (One-Way Clutch)?

When it comes to mechanical one-way clutches, Tsubaki's Cam Clutch comes to mind.

This is a mechanical non-backlash one-way clutch with an arrangement of multiple cams.

The lineup is divided into three categories: backstop, overrunning, and indexing.

What is an SR clutch (single rotation clutch)?

The SR clutch is a clutch that, with a simple lever operation, gives one or an integer number of revolutions from the continuously rotating outer race (drive side) to inner race (load side).

The mechanism in which the inner and outer race mesh enables highly reliable and accurate timing drive that is not possible with clutches using friction mechanisms, ratchet mechanisms, or pin and key mechanisms.

Clutch product list

Indexing

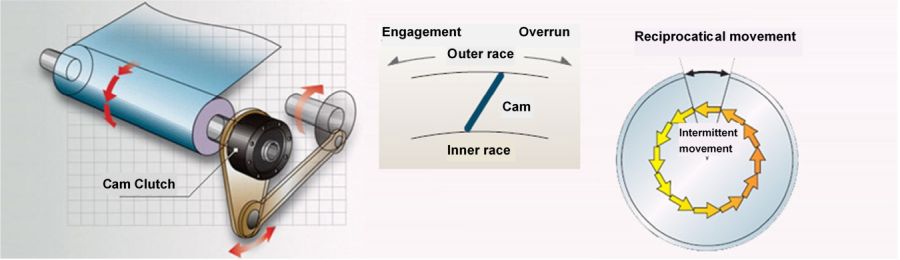

Also known as rotary intermittent feed, this mechanism converts the constant cycle motion of outer race into intermittent rotary motion and transmits it to inner race (shaft).

This method involves repeated high frequency engagement and idling.

outer race is given a reciprocating motion at a fixed angle, causing the cam clutch to alternately engage and idle continuously, resulting in intermittent feeding.

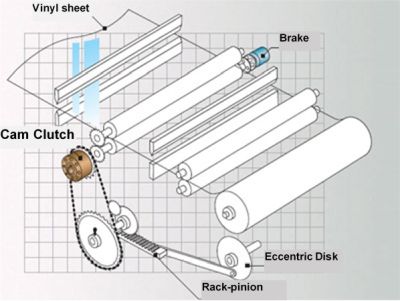

Example of sheet feeding in a bag making machine

The image on the left shows an example of use in feeding vinyl sheets into a bag making machine.

The reciprocating motion from eccentric disk is accelerated by the rack and pinion, and the reciprocating angle of the cam clutch outer race is increased.

A brake is used to improve the feeding accuracy of the vinyl sheet.

Advantages of using a Cam Clutch

- ・Higher feed frequency than servo motors is possible (maximum 1200 times/min)

- - The feed length can be adjusted continuously, eliminating the need to worry about setting parameters.

- - A low-cost indexing mechanism can be realized.

MI Series

Model number MI~

This type is capable of high-precision indexing feed.

- - Mainly used for indexing purposes.

- -High precision indexing feed is possible.

- -Ideal for applications requiring medium to low speed indexing and short feed lengths.

- - Continuous meshing operation makes it suitable for load fluctuations.

Shaft diameter range mm

Φ19~Φ250

Torque range N・m

314~176000

MI-S series

Model number MI□□-S

A cam clutch for indexing with excellent wear resistance.

- - The cam has been specially surface hardened, making it highly resistant to wear.

- -This series was specially developed for feeding materials into bag making machines and coiling machines.

- - Ideal for applications requiring slow indexing and long feed lengths.

- -This product is made to order.

Shaft diameter range mm

Φ55~Φ75

Torque range N・m

43.1~196

MX Series

Model number MX~

High feeding accuracy can be achieved during high-speed indexing.

- - It has excellent meshing response during high-speed indexing, allowing for high-precision feeding.

- - Ideal for applications with high-speed indexing and short feed lengths.

Shaft diameter range mm

Φ22~Φ70

Torque range N・m

78.4~784