Double pitch sprocket Lock Sprocket

- A sprocket integrated with a keyless fastener.

- The frictional force of the tapered sleeve allows it to be fastened to the shaft without a key.

- Installation and removal can be easily done by simply attaching and detaching the bolts.

Features

- *There is no play after installation (fastening).

- * Phase matching is also easy.

- *No need for "stopping" in the thrust direction.

- *Applicable chain sizes: [S roller type] RF2040 to RF2100, [R roller type] RF2040 to RF2100

Note: When selecting sprocket specifications

- You must select a sprocket that is compatible with your operating environment and the chain specifications you are using. For details, please refer to the compatibility chart for various chains and sprockets.

If you require a material other than steel or a surface treatment, etc., please contact us as it will be a special order item.Precautions for use

When considering Lock Sprocket, please check the following points.

- * Allowable transmission torque

Be sure to select a load torque that is equal to or less than the transmission torque indicated in the dimension table. - *Shaft bore tolerance and surface roughness

The shaft diameter tolerance should be h8 and the shaft surface roughness should be Ra3.2. - * Mounting to key groove shafts and D-shaped shafts

When mounting on a shaft that already has a keyway, such as a motor shaft, or a D-shaped shaft, the allowable torque will be reduced by 10%. - *Attachment to polished steel bars

When attached to polished steel bars with guaranteed mechanical properties (drawn material dimensions allowable diameter class 8 to 10), the allowable torque will be reduced by 10%. - *Shaft material

Please use a solid shaft material of S35C or above. - *Usage temperature range

-20℃ to 200℃ - *When tightening

When tightening bolts and nuts, always use a torque wrench and tighten them completely to the specified tightening torque.

When installing, please read Instruction Manuals that comes with the product.

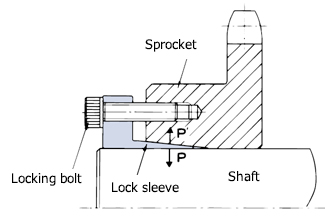

Fastening Principle

The inner diameter of the sprocket and the outer diameter of the lock sleeve are tapered, and when the fastening bolt (fastening nut) is tightened, the sprocket slides along the tapered surface.

At this time, radial forces P and P' are generated by the wedge action, pressing the shaft and the tapered inner surface, and the frictional force causes the sprocket

and firmly fastens the shaft.

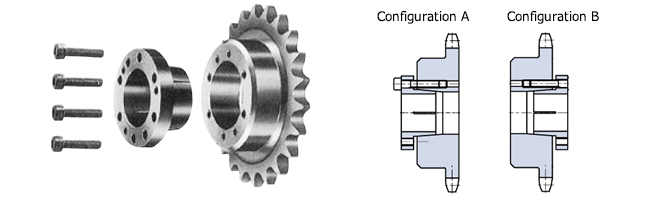

S-type structure and sleeve mounting format

Catalogs and Instruction Manuals

Model number display example

| RF2040 | S | - | 1 | B | 912T | - | S4 | 4 | 25 | A |

| | Size |

| | | |

| No. of strands |

| | | |

| | | |

| Sleeve frame number |

| | | |

| Shaft Hole Diameter mm |

| Mounting Type A or B |

||

| Roller type | Hub type | Number of teeth | Number of tightening bolts | |||||||

| 912T: 9½T (If effective number of teeth is 11, it is expressed as "1100T".) |

||||||||||

Product List

*Click to display detailed information.

| Size | Roller type | |||

|---|---|---|---|---|

| S | R | |||

| Basic model number | effective number of teeth range | Basic model number | effective number of teeth range | |

| RF2040 | RF2040S-1B□T-S○○○○● | 9½ ~ 12½ |

RF2040R-1B□T-S○○○○● | 10 ~ 16 |

| RF2050 | RF2050S-1B□T-S○○○○● | RF2050R-1B□T-S○○○○● | ||

| RF2060 | RF2060S-1B□T-S○○○○● | RF2060R-1B□T-S○○○○● | ||

| RF2080 | RF2080S-1B□T-S○○○○● | RF2080R-1B□T-S○○○○● | ||

| RF2100 | RF2100S-1B912T-S○○○○● | 9½ | RF2100R-1B1100T-S○○○○● | 11 |