Product Info High-speed lifter

Tsubaki's High-speed lifters are environmentally friendly electric lifters, and you can choose between Zip Chain mechanism or a screw mechanism.

The lineup includes scissor-type table lifters and post-type cantilever lifters.

The table lifter uses Zip Chain mechanism, allowing for high-speed, high-frequency operation and lifting.

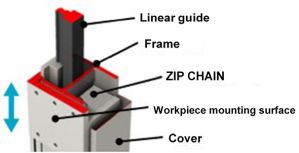

The cantilever lifter has a slim structure with a guide built into a highly rigid frame, which not only saves space but also reduces the design and installation time.

* Zip Chain mechanism is our proprietary technology in which two chains interlock like a zipper to form a single, strong pillar that can be used for both pushing and pulling.

Table of contents

High-speed lifter related information

-

Selection

-

Materials

-

Operation

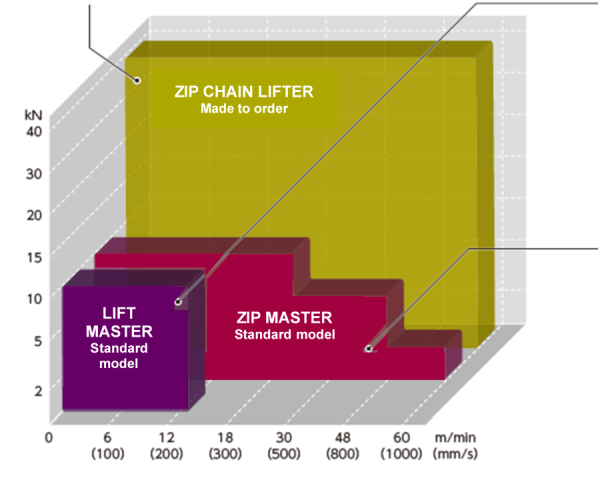

Lifter compatible range

Table lifter compatible area

Zip Chain Lifter

Scissor lifter for high-speed lifting and frequent operation

Cantilever lifter compatible area

Lift Master

No assembly required, easy installation, space-saving cantilever type!

Zip Master

Achieves high speed and high lift with a space-saving cantilever design!

Two types of lifters available

1.Scissor lifter

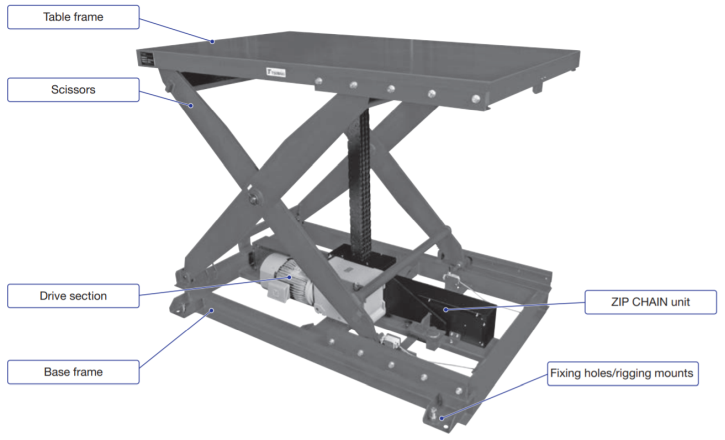

[Zip Chain Lifter] An innovative scissor lifter that uses Zip Chain

What is Zip Chain?

- High-speed, high-frequency operation

- Multi-point stop function

- By far the most space-saving

Zip Chain is a chain developed exclusively by our company, in which two chains interlock like a zipper to form one strong pillar that can be pushed and pulled.

The Tsubaki Zip Chain Actuator is a commercialized linear actuator that uses this chain.

Compared to conventional pneumatic and hydraulic cylinders, they have many features, including environmental friendliness, such as space saving, high speed and high frequency operation, multi-point stopping function, high stopping accuracy, and freedom of installation direction, and are used in a wide range of applications from small actuators to large lifters.

Overview of the device

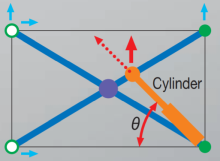

Comparison with other methods

| Zip Chain Lifter | Electric/Hydraulic Lifter |

|---|---|

|

|

Efficient transmission driveThe Zip Chain directly presses the top plate, so the motor torque is transmitted without waste. Exceptional durabilityWith the Zip Chain Lifter, the weight and thrust of the lifting section are supported by the Zip Chain, so no large forces are applied to the scissors hinges, rollers or bearings. |

Electric and hydraulic lifters require a large amount of power (1/sinθ times the lifting thrust) to be pushed up at an angle by the cylinder when starting from the lowest point. (example)  |

2.Cantilever lifter

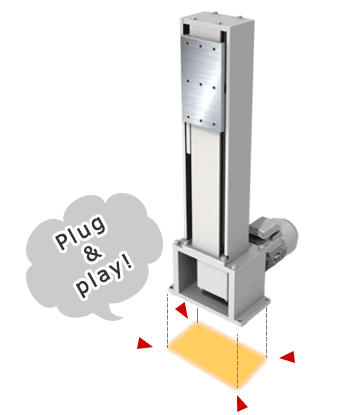

[Zip Master] A Zip Chain type cantilever lifter that can be raised and lowered quickly with plug and play

[Lift Master] Ball screw / Trapezoidal Screw type cantilever lifter that enables high-precision lifting viaplug and play.

What is Zip Chain?

- High-speed, high-frequency operation

- Multi-point stop function

- By far the most space-saving

Zip Chain is a chain developed exclusively by our company, in which two chains interlock like a zipper to form one strong pillar that can be pushed and pulled.

The Tsubaki Zip Chain Actuator is a commercialized linear actuator that uses this chain.

Compared to conventional pneumatic and hydraulic cylinders, they have many features, including environmental friendliness, such as space saving, high speed and high frequency operation, multi-point stopping function, high stopping accuracy, and freedom of installation direction, and are used in a wide range of applications from small actuators to large lifters.

plug and play type is a device that requires no assembly, is easy to set up and can be used immediately.

For plug and play type lifter

- No assembly required

- Easy installation

Ready to use

Conventional lifters...

Design, assembly, and installation man-hours

Customer's burden

plug and play type is a device that requires no assembly, is easy to set up and can be used immediately.

For plug and play type lifter

- No assembly required

- Easy installation

Ready to use

Conventional lifters...

Design, assembly, and installation man-hours

Customer's burden

| Cantilever Lifter |

Zip Master

|

Lift Master

|

|---|---|---|

| Drive system |

Interlocking chain type

Zip Chain |

Screw and nut type

Ball screw Trapezoidal Screw |

| Internal structure |

|

|

Comparison with drop lifter

Conventional vertical transport lifters require on-site assembly, and scaffolding must be set up on the ceiling to install and inspect the drive unit.

The Zip Master has an integrated structure, making it easy to assemble and install the device.

In addition, since the drive unit is located on the floor side, inspection and maintenance work is safe and easy.

High-speed lifter product list

Lift Master is a plug and play type lifter that can tolerate overhang and lateral loads.

No assembly is required; simply install it on the floor, attach the arm, and connect the power to the motor to use it immediately.

The screw shaft and guide are compactly built into a highly rigid frame to support cantilever loads (overhanging loads).

Use Ball screw type for applications where high speed, high frequency, and a long life are expected, and the economical Trapezoidal Screw type, which has self-locking properties, for applications where load retention is the main purpose at low speed and low frequency.

Lift Master Ball Screw Type

Model number LMEB~

Ball screw type compatible with servo motor drive

- ・High efficiency allows for large thrust to be obtained with a small drive source

- ・High speed operation is possible compared to Trapezoidal Screw type

- -Long life makes it suitable for high frequency operation such as on assembly lines

- plug and play type

- cantilever type

Lifting load kN

1.96~9.80

Speed mm/s

25~166

Lift Master Trapezoidal Thread Type

Model number LMEM~

Self-locking Trapezoidal Screw type

- - It is calculated to have a self-locking function, so it can be expected to hold a load.

- ・More economical than Ball screw types

- ・Ideal for infrequent operation such as maintenance purposes

- plug and play type

- cantilever type

Lifting load kN

4.90~9.80

Speed mm/s

10~15