Product Info Large size conveyor chain

Large size conveyor chain can be freely combined to transport materials in any direction, including horizontal, vertical, and inclined orientations. They can withstand temperatures up to about 200°C without the need for special materials, and heat-resistant steel is used for higher temperatures. They also come in specifications that are corrosion-resistant and chemical-resistant to water and chemicals, making them suitable for a wide range of applications.

Almost any material can be transported, from powders such as pulverized coal and cement to granular materials such as wheat and soybeans, lumps such as ore and rocks, and even products weighing several tonnes each, and there are almost no restrictions on the materials that can be transported.

Table of contents

Large size conveyor chain related information

-

Selection

-

Materials

-

Operation

Structure

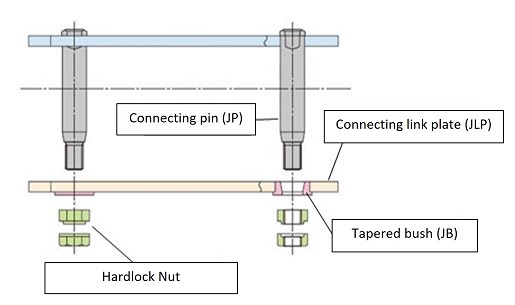

Screw Lock Link

A connecting link that enables safe and fast work.

Note: Due to the nut system, the pin length is long. Please check that it does not interfere with the device.

*The overall length tolerance for Large size conveyor chain is ±0.25%.

■ slip fit

A fit that always has a gap when the shaft and hole are combined.

A fit in which the tolerance area of the hole is entirely above the tolerance area of the shaft (pin or bush).

■ press fit

A fit that always creates an interference when the shaft and hole are combined.

A fit in which the tolerance range of the hole is completely below the tolerance range of the shaft (pin or bush).

Learn more about the components and their functions

Learn more about the components and their functions

| 1. Pin (CP) | 2. Bush (B) | |

|---|---|---|

| The most important role of pins is to connect outer link and Inner link. Like the plates, they receive chain tension in the direction of travel and reaction force from the transported goods in the perpendicular direction. Furthermore, when the chain articulate, the outer circumference of the pin slides against the inner circumference of the bushing, causing wear. Pins are an important strength component, but they also need to be wear-resistant. | The bushing is a strength component that receives the tension of the chain when it meshes with the sprocket, but its main function is as a bearing component. The outer circumference of the bushing wears out as it slides against the inner circumference of the roller when the roller rotates, and the inner circumference of the bushing wears out as it slides against the outer circumference of the pin when the chain articulate. Wear on the inner circumference of the bushing directly appears as pitch elongation. | |

| 3.Roller (RR, FR, SR, MR, NR) | 4. Plates (PLP-A, PLP-B, BLP) | |

| It has a slip fit with the bushing.. When it meshes with the sprocket, it acts as a roller, mitigating impact and wear on the tooth surface. It also rolls when traveling, reducing rolling resistance. | The plates are primarily subjected to tensile loads in the direction of chain travel, and to reaction forces at right angles to support the transported load. When the chain articulate, the outer and inner plates slide against each other, and when it engages with the sprocket, they slide against the side of the teeth. Generally, the outer plates have round or notched holes. | |

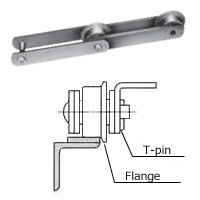

| 5. T-PIN | 6. Attachment | |

|

After press-fitting the pin into the outer plate, insert a T-pin and bend it to prevent the pin from falling out. Bend it by more than 30 degrees or until the end of the T-pin fits within the width of the plate. | This is the part that secures the attachment. For information on attachment types, see "Attachment Types" below. |

■The three basic dimensions of chains

Pitch, roller diameter, and inner link width are called the three basic dimensions of a roller chain. When these dimensions are the same, the roller chain and sprocket are dimensionally compatible.

Attachments are parts for attaching transport fixtures to chains. They can be installed at desired link intervals.

Standard Attachment

This is an economical and versatile attachment.

A attachment

It has a blade on one side.

They are called A1, A2, and A3 depending on the number of bolt holes.

A1 Attachment

A2 attachment

A3 attachment

K attachment

It has wings on both sides.

They are called K1, K2, and K3 depending on the number of bolt holes.

K1 Attachment

K2 Attachment

K3 Attachment

GA Attachment

This type has bolt holes on one side of the plate.

They are called GA2 and GA4 depending on the number of bolt holes.

GA2 attachment

GA4 attachment

Dedicated attachment

Attachments for specific applications.

Deep Link

Top Roller

outboard roller

For flow

Special attachments (Plus α conveyor chain)

A variation of the special attachment.

With SA attachment

A type with a vertical blade on one side

SK attachment included

A type with vertical blades on both sides

CA2 attachment included

Net installation

For gap-free slat installation

AA3 attachment included

Powerful type that clamps attachments

AR2 attachment included

Improved bending rigidity of A attachment

(with reinforcing ribs)

MG2 attachment included

Can be used with one type of mounting jig

With AS2 attachment

Scraper and flight mounting

AF2 attachment included

Deep scraper and flight mounting

WSA0 attachment included

Prevents transported items from spilling

With extension pin

Can be attached to the end of a pin

(Format: EN)

With stay pin

Directly mounted on connecting pin

Installation of nets, etc.

(Format: TN)

With top plate

No scratches on transported items

(Format: TP)

With trolley roller

For horizontal long distances

(Format: TRO)

With outboard roller

Supporting heavy loads

(Format: RO)

With guide shoe

Prevents lateral vibration

(Format: GS)

With guide roller

horizontal use

(Format: GR)

With fixed dog

Push and transport

(Format: KD)

With dog roller

Pushing and transporting round objects

(Format: RD)

With tilting dog

Conveyor storage

(Format: CD)

With roller tilting dog

Round object storage

(Format: RCD)

With ducking dog

Leave the transported item in its designated position

(Format: DD)

Roller type

Large size conveyor chains come in three basic roller types depending on the application.

| Large size conveyor chain basic roller type | ||

|---|---|---|

| R Roller | F Roller | S, M, N roller |

|

|

|

|

|

It helps to reduce shock and wear when the sprockets engage.

|

Learn more about how to guide the rollers

Learn more about how to guide the rollers

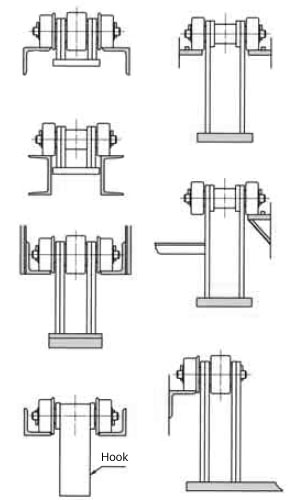

Below are examples of roller-type guide methods for the Carrying side and return-way to ensure smooth operation of Large size conveyor chain.

Guide method example

| R roller (S roller) type chain | F roller chain | Chain with outboard roller | |

|---|---|---|---|

| Carrying way |  |

|

|

| return-way |  |

|

|

Safety Precautions

Never weld additional parts to an assembled chain, as this can cause the chain to bend or twist due to plate distortion and can also cause the parts to lose hardness or become brittle due to heat.

Large size conveyor chain product list

- General-purpose and powerful

- Environmental resistance

- Bearing Roller

Conveyor Chain - Cement Conveyance

- Steel Equipment

- Biomass

- Waste Disposal Facility

- Food Industry

- Water Treatment Plant

- Automotive

- Other special uses

- Applied Equipment

Accessories

Special Large size conveyor chain (automotive industry)

This conveyor chain meets various needs for automobile manufacturing equipment, including wear resistance, positioning, accumulation, heavy load capacity, jerking prevention, and long conveyor length.

You can choose the optimal chain for each process: pressing, body welding, painting, assembly, and inspection.

Please refer to the section guide for the chains that are compatible with each process.

Bearing Bush Chain

Model number RF□□□□□R-NB~

A conveyor chain for high-precision positioning.

- - A needle bearing is used between the pin and bushing to minimize wear and elongation.

- - Suitable for transport such as positioning and tactile operation.

- ・使用雰囲気温度:-20℃~60℃

Size

RF03 tons to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

R Roller

Double Plus Conveyor Chain

Model number RF□□□□□VR~

This chain can transport and accumulate.

- During transportation, the friction between the large diameter roller and the small diameter roller causes them to rotate simultaneously, and the ratio of the roller diameters

The cargo speed is 2.3 times the chain speed. - - During accumulation, braking force acts on the large diameter roller, causing slippage between the large diameter roller and the small diameter roller, resulting in free flow.

- ・Cost reduction through energy saving:

The low coefficient of friction reduces the required power, allowing for smaller chain sizes and lower costs. - ・Long life:

Due to the large chain speed difference (1/2.3) and allowable roller load, it has more than twice the lifespan of a top roller chain. - ・Stable running:

The height from the rail to the transported goods is low, allowing for stable running.

Size

RF03トン~RF17トン

Attachment Type

None

Roller type

VR Roller

*Special sprocket

It is necessary.

Outboard Roller Chains

Model number RF□□□□□S-□□-□LSR□□~

This chain is based on the S rollers of each conveyor chain specification and has outboard roller attached.

- - The sprocket meshes with the central S roller and travel is controlled by outboard roller, resulting in stable travel.

- - Conveyor chains can be manufactured to various specifications.

- ・Application example 1:

When attaching a special attachment to the plate. - ・Application example 2:

When it is difficult to support the load with the central S roller. - ・Application example 3:

When it is difficult to guide the return side of the chain. - ・Application example 4:

When using R roller type outboard roller with double speed and accumulation functions.

Chain specifications

Manufactured to various specifications.

Size

RF03トン~RF36トン

RF430S~RF6205S

Attachment Type

Special attachments also available

We will produce it.

Roller type

S Roller

Top Roller Chains

Model number RF□□□□□S-□□-□LTR□~

A top roller is attached to the top of the chain mid-pitch, and this top roller directly transports the transported goods.

I will.

- - Top rollers can also be manufactured from engineering plastic or with bearing rollers.

- *Standard sprockets cannot be used.

A special sprocket is required, so please contact us. - ・Application example 1:

The chain operates continuously, and the conveyed items are accumulated or temporarily stopped at the stopper on the conveyor.

When you let it. - ・Application example 2:

When transport and stopping work are carried out simultaneously on the same chain.

Chain specifications

Manufactured to various specifications.

Size

RF03 ton to RF17 ton

RF6205

Attachment Type

None

Roller type

S roller, R roller, F roller

Conveyor Chain for Shower Tester and Final Inspection Lines

Model number RF□□□□□WDR・WDF~

This is an Lube-free conveyor chain that can be used in both wet and dry environments.

- - A special resin is used for the inner circumference of the roller, allowing it to be used in wet and dry conditions Lube-free, resulting in a long life.

It's a chain. - ・In automobile production facilities, shower tester lines and final inspection lines are integrated into one line, and water is often carried out.

It is effective in preventing corrosion and wear on final inspection lines.

Chain specifications

Please contact us

Size

RF10125WD~RF26300WD

Attachment Type

Please contact us

Roller type

WDR roller, WDF roller