Product Info Large size conveyor chain

Large size conveyor chain can be freely combined to transport materials in any direction, including horizontal, vertical, and inclined orientations. They can withstand temperatures up to about 200°C without the need for special materials, and heat-resistant steel is used for higher temperatures. They also come in specifications that are corrosion-resistant and chemical-resistant to water and chemicals, making them suitable for a wide range of applications.

Almost any material can be transported, from powders such as pulverized coal and cement to granular materials such as wheat and soybeans, lumps such as ore and rocks, and even products weighing several tonnes each, and there are almost no restrictions on the materials that can be transported.

table of contents

Large size conveyor chain related information

-

Selection

-

Materials

-

Operation

Structure

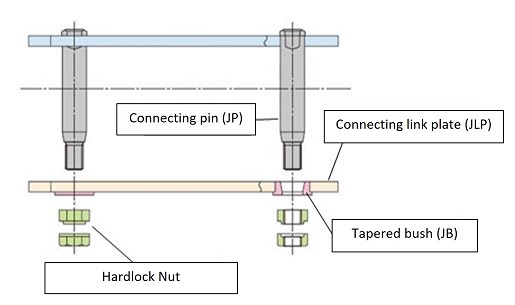

Screw Lock Link

A connecting link that enables safe and fast work.

Note: Due to the nut system, the pin length is long. Please check that it does not interfere with the device.

*The overall length tolerance for Large size conveyor chain is ±0.25%.

■ slip fit

When a shaft and a hole are fitted together, there is always a gap.

A fit in which the tolerance area of the hole is entirely above the tolerance area of the shaft (pin or bush).

■ press fit

A fit that always creates an interference when the shaft and hole are combined.

A fit in which the tolerance range of the hole is completely below the tolerance range of the shaft (pin or bush).

Learn more about the components and their functions

Learn more about the components and their functions

| 1. Pin (CP) | 2. Bush (B) | |

|---|---|---|

| The most important role of pins is to connect outer link and Inner link. Like the plates, they receive chain tension in the direction of travel and reaction force from the transported goods in the perpendicular direction. Furthermore, when the chain articulate, the outer circumference of the pin slides against the inner circumference of the bushing, causing wear. Pins are an important strength component, but they also need to be wear-resistant. | The bushing is a strength component that receives the tension of the chain when it meshes with the sprocket, but its main function is as a bearing component. The outer circumference of the bushing wears out as it slides against the inner circumference of the roller when the roller rotates, and the inner circumference of the bushing wears out as it slides against the outer circumference of the pin when the chain articulate. Wear on the inner circumference of the bushing directly appears as pitch elongation. | |

| 3.Roller (RR, FR, SR, MR, NR) | 4. Plates (PLP-A, PLP-B, BLP) | |

| It has a slip fit with the bushing.. When it meshes with the sprocket, it acts as a roller, mitigating impact and wear on the tooth surface. It also rolls when traveling, reducing rolling resistance. | The plates are primarily subjected to tensile loads in the direction of chain travel, and to reaction forces at right angles to support the transported load. When the chain articulate, the outer and inner plates slide against each other, and when it engages with the sprocket, they slide against the side of the teeth. Generally, the outer plates have round or notched holes. | |

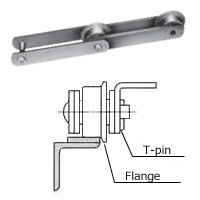

| 5. T-PIN | 6. Attachment | |

|

After press-fitting the pin into the outer plate, insert a T-pin and bend it to prevent the pin from falling out. Bend it by more than 30 degrees or until the end of the T-pin fits within the width of the plate. | This is the part that secures the attachment. For information on attachment types, see "Attachment Types" below. |

■The three basic dimensions of chains

Pitch, roller diameter, and Inner link width are called the three basic dimensions of a roller chain. When these dimensions are the same, the roller chain and sprocket are dimensionally compatible.

Attachments are parts for attaching transport fixtures to chains. They can be installed at desired link intervals.

Standard Attachment

This is an economical and versatile attachment.

A attachment

It has a blade on one side.

They are called A1, A2, and A3 depending on the number of bolt holes.

A1 Attachment

A2 attachment

A3 attachment

K attachment

It has wings on both sides.

They are called K1, K2, and K3 depending on the number of bolt holes.

K1 Attachment

K2 Attachment

K3 Attachment

GA Attachment

This type has bolt holes on one side of the plate.

They are called GA2 and GA4 depending on the number of bolt holes.

GA2 attachment

GA4 attachment

Dedicated attachment

Attachments for specific applications.

Deep Link

Top Roller

outboard roller

For flow

Special attachments (Plus α conveyor chain)

A variation of the special attachment.

With SA attachment

A type with a vertical blade on one side

SK attachment included

A type with vertical blades on both sides

CA2 attachment included

Net installation

For gap-free slat installation

AA3 attachment included

Powerful type that clamps attachments

AR2 attachment included

Improved bending rigidity of A attachment

(with reinforcing ribs)

MG2 attachment included

Can be used with one type of mounting jig

With AS2 attachment

Scraper and flight mounting

AF2 attachment included

Deep scraper and flight mounting

WSA0 attachment included

Prevents transported items from spilling

With extension pin

Can be attached to the end of a pin

(Format: EN)

With stay pin

Directly mounted on connecting pin

Installation of nets, etc.

(Format: TN)

With top plate

No scratches on transported items

(Format: TP)

With trolley roller

For horizontal long distances

(Format: TRO)

With outboard roller

Supporting heavy loads

(Format: RO)

With guide shoe

Prevents lateral vibration

(Format: GS)

With guide roller

horizontal use

(Format: GR)

With fixed dog

Push and transport

(Format: KD)

With dog roller

Pushing and transporting round objects

(Format: RD)

With tilting dog

Conveyor storage

(Format: CD)

With roller tilting dog

Round object storage

(Format: RCD)

With ducking dog

Leave the transported item in its designated position

(Format: DD)

Roller type

Large size conveyor chains come in three basic roller types depending on the application.

| Large size conveyor chain basic roller type | ||

|---|---|---|

| R Roller | F Roller | S, M, N roller |

|

|

|

|

|

It helps to reduce shock and wear when the sprockets engage.

|

Learn more about how to guide the rollers

Learn more about how to guide the rollers

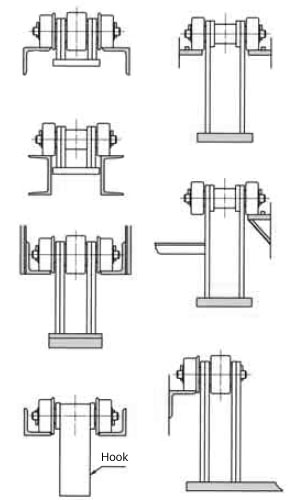

Below are examples of roller-type guide methods for the Carrying side and return-way to ensure smooth operation of Large size conveyor chain.

Guide method example

| R roller (S roller) type chain | F roller chain | Chain with outboard roller | |

|---|---|---|---|

| Carrying way |  |

|

|

| return-way |  |

|

|

Safety Precautions

Never weld additional parts to an assembled chain, as this can cause the chain to bend or twist due to plate distortion and can also cause the parts to lose hardness or become brittle due to heat.

Large size conveyor chain product list

- General-purpose and powerful

- Environmental resistance

- Bearing Roller

Conveyor Chain - Cement Conveyance

- Steel Equipment

- Biomass

- Waste Disposal Facility

- Food Industry

- Water Treatment Plant

- Automotive

- Other special uses

- Applied Equipment

Accessories

Special Large size conveyor chain (water treatment facility)

This conveyor chain is designed specifically for water treatment equipment.

The drive chains for the scraper, sand scraper, water screen and each device can be selected from the most suitable materials (stainless steel, engineering plastic).

Please refer to Selection Guide for chains that can be used in each process of a water treatment facility.

Sediment Collector Chain ACR, ACP, ACS types

Model number ACP04152/P~, ACR8□□~, ACS□□□□□~

Sediment Collector Chain used in settling tanks at water treatment facilities.

- ACP type:

Combined with a plastic sprocket, it has excellent wear resistance and corrosion resistance, and is lighter than steel chains.

This reduces power consumption and improves economy. - ・ACR type:

The roller chain and tooth block sprocket allow for rolling contact, improving wear resistance.The lightweight chain also reduces drive power, improving economy. - ・ACS type:

This chain is the first in the industry to use tempered stainless steel material, improving wear resistance and corrosion resistance.

The chain is bushed chain with no rollers. It can also be manufactured using the stainless steel 300 series.

(Please contact us for details)

size

ACP04152,

ACR810~ACR819

ACS13~ACS35

Attachment Type

SF4 etc.

Roller type

ACR:

S Roller

ACP, ACS:

bushed chain

Water Screen Chain JAC type

Model number JAC□□□□□~

This chain is used in water screens and drainage machines at water treatment facilities.

- By combining materials, you can select the chain that best suits your application.

- ・NVJ:

The most economical, strongest and most wear-resistant chain. - ・PJ(PJH):

This chain has excellent wear resistance and corrosion resistance. - ・PJW (PJWH):

Compatible with two PJ series flanges, suitable for preventing falling off from guide channel. - ・SJ:

This chain has the best corrosion resistance. - ・SJW:

Compatible with two SJ series flanges, suitable for preventing falling off from guide channel. - ・NSJ:

Compared to the SJ specification, the wear resistance between the bushing and roller is 1.5 times higher. NETIS registered (Registration number: KT-230284-A) - ・NSJW:

Compared to the SJW specification, the wear resistance between the bushing and roller is 1.5 times higher. NETIS registered (Registration number: KT-230284-A) - ・FP-SJW:

This chain uses resin F rollers to reduce running noise.

*PJH and PJWH are heavy-duty models. The heavy-duty models have wider plates on Inner link.

Chain specifications

NVJ specification, PJ specification, PJW specification, SJ specification, SJW specification, NSJ specification, NSJW specification, FP-SJW specification

size

JAC08 ton to JAC26 ton

JAC6205

Attachment Type

Y, A2

Roller type

R roller, F roller,

S roller, FP roller

For water screens WAC type

Model number WAC□□610~

Chain for automatic dust removal machines at water intakes of thermal power plants, etc.

- - The pins, bushings and rollers are made of stainless steel 400 series, and all are tempered.

- - Excellent corrosion resistance and abrasion resistance required for reciprocating movement between seawater and air.

- ・Special resin is used as the bearing material for the inner diameter of the roller, and seawater is used as a lubricant (no grease required).

Easy to maintain.

size

WAC25610~WAC120610

Attachment Type

none

Roller type

R Roller

Conveyor Chain for Water Treatment Plants BF Type

Model number BF□□□~, ACS4124~

This drive chain uses refined stainless steel material to improve wear resistance and corrosion resistance.

- -Can also be manufactured using stainless steel 300 series materials.

- - Roller chain sprockets can be used.

- -It is a bushed chain.

size

BF120~BF240

ACS4124, BF2120

Conveyor Chain for Water Treatment Plants ACRD Type

Model number ACRD□□~

A drive roller chain made of stainless steel 400 series, exclusively for water treatment equipment.

- - The roller chain allows for rolling contact with the sprocket, improving wear resistance.

size

ACRD08~ACRD17

Conveyor Chain for Water Treatment Plants EPCD Type

Model number EPC□□D~

This is a dedicated drive chain for resin scrapers that combines engineering plastic and stainless steel 300 series pins.

- -It is a bushed chain.

size

EPC78D, EPC90D