Product Info Power-Lock (Fastener)

Power-Lock is a type of friction locking device that fastens a shaft and boss simply, strongly, securely and without backlash.

Because it is fastened by friction using the wedge principle, there is no need to use keys or set screws; the shaft and boss can be fastened simply by tightening the bolt, and removal is also easy.

The lineup includes steel, stainless steel, and coated materials, making it suitable for use in a variety of situations.

table of contents

Power-Lock Related Information

-

Selection

-

Materials

-

Operation

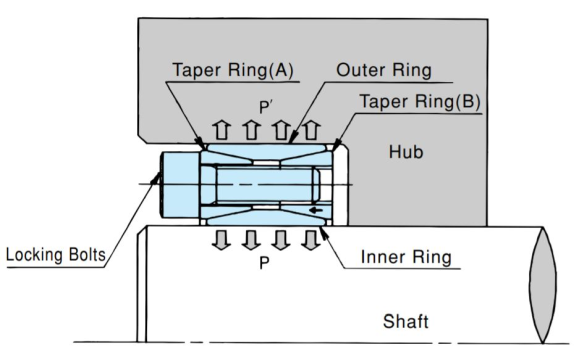

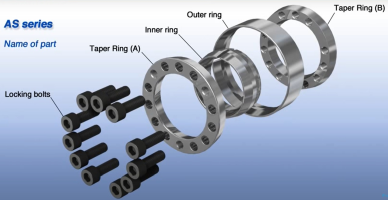

Basic structure

- Double Taper Type (e.g. AS series)

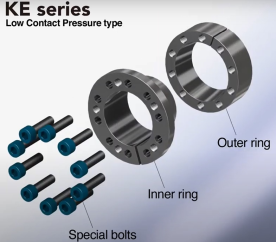

- Single Taper Type (e.g. KE series)

Fastening Principle

- Double Taper Type

The inner diameters of tapered rings A and B are tapered and come into contact with the tapers on the inner diameters of the outer and inner races.

By tightening the fastening bolts, tapered rings A and B move closer together, generating Pressing force P and P' on the inner race. These Pressing force P and P' generate a frictional force that completely fastens the boss and shaft.

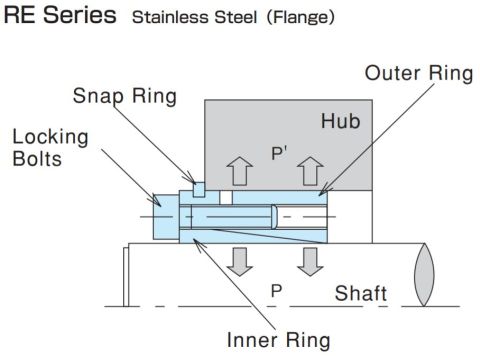

- Single Taper Type

The inner diameter of the outer ring and the outer diameter of the inner ring are tapered, and by tightening the fastening bolts, the outer ring moves while sliding along the tapered surface and the inner surface of the boss.

At this time, radial forces P and P' are generated by the wedge action, pressing the shaft and the inner surface of the hub. These forces P and P' generate frictional forces that firmly fasten the hub and shaft together.

Features

- ・The cost of machining the shaft and hub is low (no keyway machining required).

- -No backlash (play), making it ideal for high-precision position control.

- ・No need to worry about shaft thinning or seizure (no need to worry about wear)

- · Easy phase alignment, which is advantageous for positioning cams and gears.

- ・Assembly and disassembly are easy and do not require the same level of skill as shrink fitting.

- - Can withstand thrust loads, so no need for retainers.

- - The keyway does not reduce the strength of the shaft.

- · Better rotational balance compared to key fastening.

Precautions

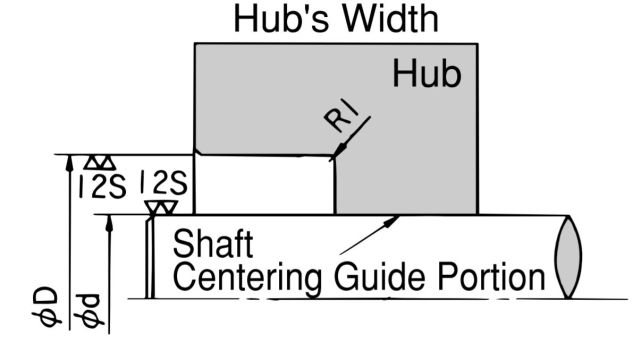

・Depending on the series, Power-Lock may or may not have a centering function.

See a detailed explanation of the centering function

See a detailed explanation of the centering function

The centering function is a function that suppresses the runout of the boss when the shaft and boss are fastened together.

In other words, it's a function of how close you can bring the axis to the center of the boss.

There are two types of Power-Lock: one with a centering function and one without.

For series without this, it is necessary to provide a guide section on the boss (the part where the shaft and boss come into direct contact).

Practical centering accuracy can be achieved by setting the guide length to half the shaft diameter.

- The boss will move during assembly depending on whether or not there is a flange.

See detailed explanation about boss movement during assembly

See detailed explanation about boss movement during assembly

*The image of the RE-SS series, which can be selected with or without a flange (retaining ring), is provided for reference.

In the series with flanges, when tightening the tightening bolts, the flange acts as a stopper to stop the boss from moving forward together with the outer ring.

The outer ring slides on the inner surface of the boss.

However, in a straight installation without a flange (upper right diagram), there is no stopper, so when the bolt is tightened, the boss moves forward along with the outer ring.

(However, since there is no loss due to sliding, the transmitted torque is higher.)

If you are concerned about the boss moving, choose a type that does not have a moving boss.

Power-Lock Product List

Standard Specifications

You can choose the most suitable Power-Lock from our extensive lineup.

Applicable shaft diameters range from a small diameter of Φ5 to a maximum of Φ500, and the series cater to a wide range of needs, from highly compatible general-purpose models to types compatible with small hub diameter (hubs), large capacity types, external tightening types, nut tightening types, and types compatible with a wide range of shaft tolerances.

KE Series

Model number PL□□X□□KE

With a lineup starting from small diameter shafts, it can be used for shafts with a wide range of tolerances.

- ・Compatible with a wide range of shaft tolerances. Standard products are compatible with plus tolerance shafts of servo motors, etc.

- - The small inner/outer diameter ratio allows for compatibility with small hub diameter. Compact design is possible.

- - With a lineup starting from small diameter sizes, it is ideal for fastening small stepping motors and servo motor output shafts.

- - Simple structure with few parts, excellent cost performance.

- -In addition to stainless steel and electroless nickel plating specifications, we also offer Low Contact Pressure series.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ5~Φ100

Torque Range

7.5~9900N・m

Applicable tolerance

Axis: h6, h7, js6, js7, k6, m6

hub bore: H8

Applicable surface roughness

Ra1.6

AS Series

Model number PL□□X□□AS

This is the most popular global standard model.

- - This series is highly compatible and is available from many manufacturers both domestically and internationally.

- - By using high-strength bolts, fewer tightening bolts are required than other companies' products, reducing assembly time.

- - The large taper angle makes it easy to tighten and remove. It is the easiest to handle in the series.

- ・We cover a wide range of shaft diameters from Φ19 to Φ500. Inch sizes are also available.

- ・Stainless steel and electroless nickel plating specifications are also available. Choose according to your application.

- *It does not have a centering function, so a guide must be provided on the boss.

- *The boss does not move during assembly.

Taper Specifications

Double Taper

Centering function

none

Applicable shaft diameter

Φ19~Φ500

Torque Range

294~555000N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

AD-N Series

Model number PL□□X□□AD-N

Large capacity torque transmission type.

- -It has a transmission torque capacity 1.5 to 3 times greater than the AS series.

- · It has the same inner and outer diameter as the AS series, making it easy to replace multiple AS series units.

- ・Electroless nickel plating specifications are also available. Ideal for transmitting large torque in clean rooms.

- ・Tsubaki is the only company that offers a lineup starting from Φ19. Leave the transmission of large torque on small diameter shafts to us.

- * Careful assembly and removal is required.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Double Taper

Centering function

Provided

Applicable shaft diameter

Φ19~Φ300

Torque Range

382~429000N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

AE Series

Model number PL□□X□□AE

It has the same inner and outer diameter as the AS series, but comes with a flange and centering function.

- - It has the same inner and outer diameter as the AS series, and is suitable for cases where a centering guide section cannot be installed.

- - A simple type consisting of three parts: inner ring, outer ring, and tightening bolt.

- - This series is highly compatible and is available from many manufacturers both domestically and internationally.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

- *When mounting on a stepped shaft, leave a gap of 1 mm or more between the boss and the stepped part.

If there is no gap, it may be difficult to remove.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ19~Φ150

Torque Range

265~27000N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

TF Series

Model number PL□□X□□TF

This series has the smallest inner and outer diameter ratio and is ideal for small hub diameter.

- - The smallest inner/outer diameter ratio in the series, so it can be used even when the boss diameter is small.

- - The number of tightening bolts is the smallest in the series, reducing assembly time.

- - This series is highly compatible and is available from many manufacturers both domestically and internationally.

- - Electroless nickel plating specifications are also available.

- - It consists of four parts: inner ring, outer ring, spacer, and tightening bolt.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ6~Φ90

Torque Range

11~8820N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

EL Series

Model number PL□□X□□E

This is the simplest element type and allows for optimal design.

- ・Bolt tightening and the number of Power-Lock ELs to be installed can be freely selected, allowing you to select the optimum tightening force depending on the required tightening force.

Design is possible. - The perfect ring shape provides excellent dynamic balance.

- - Compact and lightweight, it does not take up more space than necessary for installation.

- - It is inexpensive and suitable for large-scale use.

- - This series is highly compatible and is available from many manufacturers both domestically and internationally.

- *The pressure flange, pressure sleeve, and tightening bolts must be provided by the customer.

- *Outer ring pressure is the standard, in which case the boss does not move during assembly.

- *It does not have a centering function, so a guide must be provided on the boss.

Taper Specifications

Single Taper

Centering function

none

Applicable shaft diameter

Φ10~Φ150

Torque Range

6.9~10500N・m

Applicable tolerance

shaft:

Φ10~38 h6

Φ40 or more h8

hub bore:

Φ10~38 H7

Φ40 or more H8

Applicable surface roughness

Ra0.8

EF Series

Model number PL□□X□□EF

It is a pressure flange integrated type with the same inner and outer diameter as the EL series.

- · It is an integrated pressure flange with the same inner and outer diameter as the EL series, eliminating the need to manufacture a pressure flange.

- -It has 2 to 3 times the transmission torque of the EL series, so it can be used as a replacement for multiple ELs.

- - The small inner/outer diameter ratio allows it to be used with small hub diameter.

- - A simple type consisting of three parts: inner ring, outer ring, and tightening bolt.

- ・This is a Tsubaki-exclusive series that is not available from other companies.

- *Centering function included. No need for troublesome boss step processing.

- *When assembling, the boss will move slightly forward in the axial direction. Please contact us for details.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ10~Φ120

Torque Range

39~12600N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

ML Series

Model number PL□□X□□M/MG

A simple fastening type that can be easily fastened with just one nut.

- - Can be easily fastened with just one nut, significantly reducing assembly time.

- - The surface is plated for simple rust prevention, and the nuts also have a special surface treatment, so there is no need to apply oil during assembly.

- -The only one in the series that can be attached to bosses that are shorter than Power-Lock length.

- · The tightening torque can be changed within the range of 1/2 to 1.1 times the standard torque. It can be used to match the boss strength.

- *Shaft diameters up to Φ32 are ML type, and Φ34 and above are MG type, and the appearances are different.

- *Centering function included. No need for troublesome boss step processing.

- *When assembled, the boss will move slightly toward the rear in the axial direction. Please contact us for details.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ5~Φ75

Torque Range

6.76~2000N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

SL Series

Model number PL□□X□□SL

This is an external tightening type that tightens from the outside of the boss.

- - Ideal for fastening hollow shafts such as reducers.

- -It can also be used when the boss thickness cannot be secured due to the design.

- - Special surface treatment has been applied, so there is no need to apply oil during assembly.

- - The thicker the shaft diameter, the greater the torque that can be transmitted.

- - Simple structure makes it easy to install and remove.

- *The boss does not move during assembly.

- *If used with a hollow shaft, the inner diameter of the hollow shaft must be considered when selecting.

Taper Specifications

Double Taper

Centering function

Not required as it is an external tightening type

Applicable outer hub diameter

Φ24~Φ300

Torque Range

167~290000N・m

Applicable tolerance

outer hub diameter: h7 hub bore: H7

Applicable surface roughness

Ra1.6