Product Info Power-Lock (Fastener)

Power-Lock is a type of friction locking device that fastens a shaft and boss simply, strongly, securely and without backlash.

Because it is fastened by friction using the wedge principle, there is no need to use keys or set screws; the shaft and boss can be fastened simply by tightening the bolt, and removal is also easy.

The lineup includes steel, stainless steel, and coated materials, making it suitable for use in a variety of situations.

table of contents

Power-Lock Related Information

-

Selection

-

Materials

-

Operation

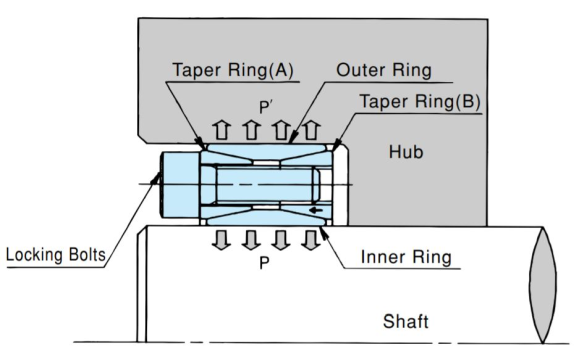

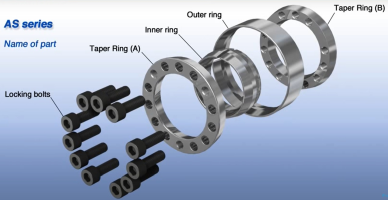

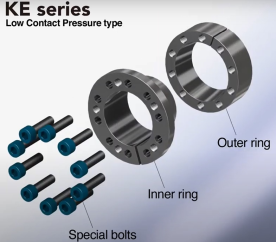

Basic structure

- Double Taper Type (e.g. AS series)

- Single Taper Type (e.g. KE series)

Fastening Principle

- Double Taper Type

The inner diameters of tapered rings A and B are tapered and come into contact with the tapers on the inner diameters of the outer and inner races.

By tightening the fastening bolts, tapered rings A and B move closer together, generating Pressing force P and P' on the inner race. These Pressing force P and P' generate a frictional force that completely fastens the boss and shaft.

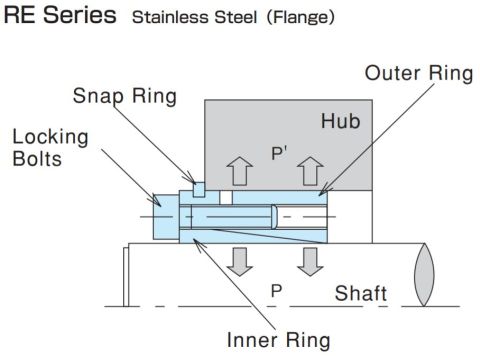

- Single Taper Type

The inner diameter of the outer ring and the outer diameter of the inner ring are tapered, and by tightening the fastening bolts, the outer ring moves while sliding along the tapered surface and the inner surface of the boss.

At this time, radial forces P and P' are generated by the wedge action, pressing the shaft and the inner surface of the hub. These forces P and P' generate frictional forces that firmly fasten the hub and shaft together.

Features

- ・The cost of machining the shaft and hub is low (no keyway machining required).

- -No backlash (play), making it ideal for high-precision position control.

- ・No need to worry about shaft thinning or seizure (no need to worry about wear)

- · Easy phase alignment, which is advantageous for positioning cams and gears.

- ・Assembly and disassembly are easy and do not require the same level of skill as shrink fitting.

- - Can withstand thrust loads, so no need for retainers.

- - The keyway does not reduce the strength of the shaft.

- · Better rotational balance compared to key fastening.

Precautions

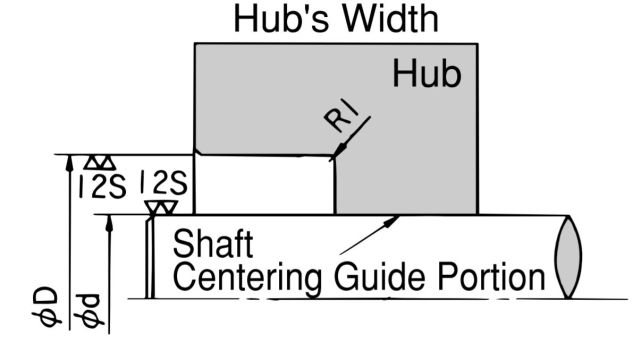

・Depending on the series, Power-Lock may or may not have a centering function.

See a detailed explanation of the centering function

See a detailed explanation of the centering function

The centering function is a function that suppresses the runout of the boss when the shaft and boss are fastened together.

In other words, it's a function of how close you can bring the axis to the center of the boss.

There are two types of Power-Lock: one with a centering function and one without.

For series without this, it is necessary to provide a guide section on the boss (the part where the shaft and boss come into direct contact).

Practical centering accuracy can be achieved by setting the guide length to half the shaft diameter.

- The boss will move during assembly depending on whether or not there is a flange.

See detailed explanation about boss movement during assembly

See detailed explanation about boss movement during assembly

*The image of the RE-SS series, which can be selected with or without a flange (retaining ring), is provided for reference.

In the series with flanges, when tightening the tightening bolts, the flange acts as a stopper to stop the boss from moving forward together with the outer ring.

The outer ring slides on the inner surface of the boss.

However, in a straight installation without a flange (upper right diagram), there is no stopper, so when the bolt is tightened, the boss moves forward along with the outer ring.

(However, since there is no loss due to sliding, the transmitted torque is higher.)

If you are concerned about the boss moving, choose a type that does not have a moving boss.

Power-Lock Product List

Depending on the environment in which you will be using it, you can choose the most suitable Power-Lock from our extensive lineup.

This is Power-Lock that can be used in a variety of environments.

We offer a range of products, including stainless steel specifications that can be used in applications where water comes into direct contact with the product or in environments where high corrosion resistance is required, and electroless nickel plating specifications that are ideal for simple rust prevention in clean rooms, etc.

Stainless steel specifications

It is suitable for applications requiring high corrosion resistance, such as applications where it will be exposed to direct water. Choose from three series depending on your application.

Although the dimensions are compatible with the standard series, please note that the transmission torque will be reduced.

The tightening bolts are made of stainless steel with a special lubricating coating on the surface, so there is no need to apply oil during assembly.

KE-SS series

Model number PL□□X□□KE-SS

Stainless steel specification of the KE series for small diameter shafts.

- - The main body is made of austenitic stainless steel, which provides high corrosion resistance.

- - The tightening bolts have a special lubricating coating, so there is no need to apply oil during assembly.

- ・Compared to other companies' products, it has a high transmission torque while being designed to suppress generated surface pressure, so it can be used on small hub diameter.

Additionally, the number of tightening bolts is small, which reduces assembly work. - · As with the KE series, this standard product is compatible with positive tolerance shafts of servo motors, etc.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ5~Φ50

Torque Range

5.0~836N・m

Applicable tolerance

Axis: h6, h7, js6, js7, k6, m6

hub bore: H8

Applicable surface roughness

Ra1.6

AS-SS Series

Model number PL□□X□□AS-SS

This is the stainless steel specification of the global standard model AS series.

- - Suitable for use in harsh environments with corrosive atmospheres.

- The main body is made of austenitic stainless steel, and the fastening bolts (M12 and below) are made of stainless steel (SUH660) with a special lubricating coating on the surface. This prevents rust and provides a stable friction coefficient, maintaining high performance.

- ・Due to the above, there is no need to apply oil during assembly.

- This reduces assembly work.

- *It does not have a centering function, so a guide must be provided on the boss.

- *The boss does not move during assembly.

Taper Specifications

Double Taper

Centering function

none

Applicable shaft diameter

Φ19~Φ150

Torque Range

196~20900N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

RE-SS Series

Model number PL□□X□□RE-SS

This is a series designed specifically for stainless steel, with two installation methods to choose from.

- - By attaching or detaching the included retaining ring, you can choose between two mounting methods: flange type and straight type.

- - The main body is made of austenitic stainless steel, which provides high corrosion resistance.

- - The tightening bolts have a special lubricating coating, so there is no need to apply oil during assembly.

- - The product lineup includes small diameter shafts and has higher transmission torque than the KE-SS series.

- *Centering function included. No need for troublesome boss step processing.

- * In the case of flange type, the boss does not move during assembly, but in the case of straight type, the boss moves during assembly.

It moves slightly forward in the axial direction. Please contact us for details.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ5~Φ50

Torque Range

5.01~1170N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

Electroless nickel plating specifications

Suitable for relatively simple rust prevention applications such as use in clean rooms. Dimensions are compatible with the standard series, and there is no reduction in transmission torque.

The tightening bolts have been given a special surface treatment that provides lubrication, so there is no need to apply oil during assembly.

Choose from four series to suit your needs.

KE-KP series

Model number PL□□X□□KE-KP

Electroless nickel plating specification for the KE series, which supports small diameter shafts.

- · Both dimensions and transmission torque are the same as the KE standard series. There is no torque reduction.

- - The main body is electroless nickel plated, which does not peel off.

- - The tightening bolts have been given a special surface treatment that provides lubrication, so there is no need to apply oil during assembly.

It is chrome-free and environmentally friendly. - *Please note that the applicable shaft tolerance is h8 and hub bore tolerance is H8.

- *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ5~Φ100

Torque Range

7.5~9900N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

AS-KP Series

Model number PL□□X□□AS-KP

This is the global standard model AS series with electroless nickel plating.

- - The main body is electroless nickel plated, which does not peel off.

- - The tightening bolts have been given a special surface treatment that provides lubrication, so there is no need to apply oil during assembly.

It is chrome-free and environmentally friendly. - - Like the standard specification, it uses fewer tightening bolts than other companies' products, reducing assembly time.

- · The dimensions are the same as the standard AS series specifications, making switching easy.

- *It does not have a centering function, so a guide must be provided on the boss.

- *The boss does not move during assembly.

Taper Specifications

Double Taper

Centering function

none

Applicable shaft diameter

Φ19~Φ300

Torque Range

245~151000N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

TF-KP series

Model number PL□□X□□TF-KP

TF series for small hub diameter, electroless nickel plating specification.

- · Both dimensions and transmission torque are the same as the TF standard series. There is no torque reduction.

- · With a small inner and outer diameter ratio and a lineup starting from Φ10, it is ideal for small hub diameter, just like the standard series.

- - The main body is electroless nickel plated, which does not peel off.

- - The tightening bolts have been given a special surface treatment that provides lubrication, so there is no need to apply oil during assembly.

It is chrome-free and environmentally friendly. - *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Single Taper

Centering function

Provided

Applicable shaft diameter

Φ10~Φ90

Torque Range

44~8820N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6

AD-N-KP Series

Model number PL□□X□□AD-N-KP

This is the electroless nickel plated version of the large-capacity torque transmission type AD-N series.

- - Mainly suitable for applications requiring large torque, such as fixing the wheel axles of trolleys in clean rooms.

- · Both dimensions and transmission torque are the same as the AD-N standard series. There is no torque reduction.

- - The main body is electroless nickel plated, which does not peel off.

- - The tightening bolts have been given a special surface treatment that provides lubrication, so there is no need to apply oil during assembly.

It is chrome-free and environmentally friendly. - *Centering function included. No need for troublesome boss step processing.

- *The boss does not move during assembly.

Taper Specifications

Double Taper

Centering function

Provided

Applicable shaft diameter

Φ50~Φ100

Torque Range

4210~26500N・m

Applicable tolerance

Shaft: h8 Hub Bore: H8

Applicable surface roughness

Ra1.6