Roller chain coupling stainless steel series (wrap type coupling)

- Austenitic stainless steel is used for the roller chain and sprockets.

- It can also be used in harsh environments that were difficult for conventional steel Roller chain coupling to handle.

- ・Applicable shaft diameter: Φ11mm to Φ140mm

- Torque range: 74 to 5883 Nm

Features

-

・Excellent corrosion resistance

Suitable for use outdoors or in corrosive atmospheres such as acidic or alkaline.

[Major applications]: Water gates, food machinery (brewing, fermented foods), rigging equipment, etc.

-

・Operating temperature range

Without case: -20 to 200°C / With case: -10 to 80°C

*Please contact us if you plan to use the product with a case at temperatures exceeding 80°C.

-

・Clean quality

It has high rust prevention properties and is highly compatible with fluorine-based greases for food machinery and clean rooms.

-

・Quick delivery

CR4012 to CR6022: 2 weeks for pilot bore products, 3 weeks for processed shaft holes.

CR8018 to CR12022: Both pilot bore and bore-machined products can be delivered in 4 weeks, and large sizes can also be delivered in a Quick delivery.

Chemical resistance table

| Drug/food name | Resistance | Drug/food name | Resistance | Drug/food name | Resistance |

|---|---|---|---|---|---|

| acetone | ● | 30% hydrogen peroxide | ● | vinegar | ▲ |

| alcohol | ● | Formic acid 50% | ● | Potassium hydroxide 20% | ● |

| Ammonia water | ● | Chromic acid 5% | ● | Sodium hydroxide 25% | ● |

| Zinc chloride 50% | ▲ | Acetic acid 10% | ● | Concentrated nitric acid 65% | ● |

| Ferric chloride 5% | ▲ | calcium hypochlorite | ● | Boric acid 50% | ● |

| Sodium chloride 5% | ● | Sodium hypochlorite 10% | × | Sulfuric acid 5% | × |

| Hydrochloric acid 2% | × | Oxalic acid 10% | ● | Zinc sulfate 25% | ● |

| sea water | ▲ | Nitric acid 5% | ● | Phosphoric acid 5% | ● |

-

●: Chemical resistant ▲: Chemical resistant depending on usage conditions ×: Not chemical resistant

Chemical resistance varies considerably depending on the conditions of use, so it is not a guarantee.

Please refer to the table above and confirm chemical resistance under actual usage conditions before deciding on specifications.

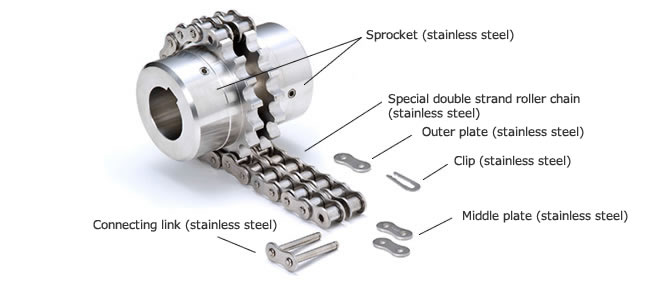

Structure

-

-The main body consists of an austenitic stainless steel sprocket and a dedicated two-row roller chain (stainless steel).

- Stainless steel joint links and spring clip are also included as special parts.

Case (sold separately)

Be sure to use the case in the following cases:

- (1) When used at high rotation speeds.

- (2) When used in an abrasive atmosphere such as dusty areas.

- (3) When used in a corrosive atmosphere such as a humid environment.

- - A dedicated case for the Roller chain coupling series.

- - By attaching it to a chain coupling, it prevents lubricant from scattering and dust from entering, extending the life of the coupling.

- - It has a split shape that can be separated perpendicular to the axis, making it convenient for installation and inspection.

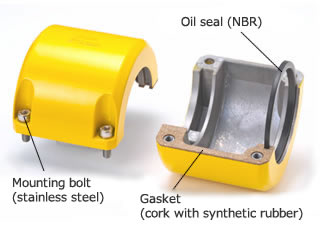

Case Structure

- -The case is made of die-cast aluminum and has a two-part structure, with gaskets (cork with synthetic rubber) attached to the mating surfaces.

- - Parts include four hex socket bolts and a dedicated oil seal (NBR).

- ・Oil seals and packings are sold as individual parts. Lubricating grease must be purchased separately.

Click here for recommended grease products

- - Install the oil seal on the side with the greatest vibration.

- - When using vertically, the oil seal side should be on the top side.

If you would like to take measures to prevent grease leakage, a quote will be required, so please contact us. - -Painting specifications: Melamine resin baked paint

- -Paint color: Munsell 8.1YR7.6/15.2 Orange Yellow

Catalogs and Instruction Manuals

Model number display example

| CR | 40 | 12 | H | - | SS |

| | Series |

| Chain number |

| Number of sprocket teeth |

| H: Main unit K: Case |

| SS: Stainless steel series |

|

Product model number list

*Click on the model number to display detailed information.