Product Info Top chain

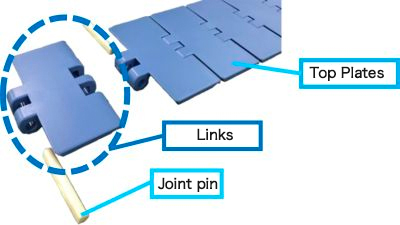

Top chain is a conveyor chain in which the top plate and chain section are integrated and connected by a joint pin.

There are Plastic top chain, which has plastic plates that prevent scratches on the transported objects, and Stainless Steel Top chain which has stainless steel plates that are highly corrosion-resistant and suitable for transporting heavy objects.

Our lineup also includes Snap top chain, which are steel chains with plastic plates attached, and accumulation chains, which have rollers built into the top plate.

Table of contents

Top chain Related Information

-

Selection

-

Materials

-

Operation

Top chain Features

Common Features

- Feature 1Protection of transported items: Prevents scratches on products caused by sliding >>See details

- Feature 2: A wide range of top plate widths and shapes are available >>See details

- Feature 3: Extensive lineup of curved conveyor chains >>See details

Protection of transported items: Reduces scratches caused by sliding

Its excellent sliding properties prevent scratches on valuable products and parts caused by sliding.

A lineup of various top plate widths and shapes

With a wide variety of types available, you can select a chain that best suits the items you are transporting.

A wide range of curved conveyor chains are also available

A wide variety of chain pitches and widths are available, allowing for a variety of curved conveyances.

Features of Plastic Top Chain and Stainless Steel Top chain

Prevents scratches on transported items

This conveyor chain is made by molding the chain and plastic plate, which prevents scratches on the transported items, into one piece and connecting them with joint pins.

The self-lubricating properties of the plastic mean that it can be used without oiling, helping to keep the work site clean.

It can be used in a wide range of applications, such as in environments where oil is undesirable and to prevent scratches on products, and is used in a wide range of industries.

We have a wide range of chain specifications (materials) available, allowing you to choose the one that best suits your usage environment.

Other Plastic top Chains

Snap Top Chain

- - It consists of a main chain and a top plate, and the legs of the top plate are snapped onto outer link of the main chain.

- - Large allowable tension makes it ideal for conveyors with large transport capacity (excluding SS Series and PC specifications)

- ・Only the top plate can be replaced

- ・A lineup of chain specifications suited to corrosion conditions

Plastic Universal Chain

- ・The small bending radius allows for effective use of narrow spaces

- ・The structure minimizes gaps between chain links, making it ideal for stable transport of transported items.

Gripper Chain

- - It consists of a main chain, top plate, and grip rubber, and the top plate and grip rubber are replaceable.

- - Grips the transported item from both sides, making it ideal for lifting and lowering the transported item.

- ・Grip rubber shape and material can be selected

Plastic Crescent Chain

- ・Ideal for horizontal circulation transport

- ・The gap between the chain links is constant, allowing for more stable transport of transported goods.

Accumulation Chain

- - Rolling of the rollers on the chain surface prevents scratches on transported items

- ・Ideal for reducing scratches on the bottom of transported items and line pressure in applications with accumulation

Plastic Roller Table

- ・Free-flow chain that can be directly loaded without a pallet

- ・The rolling of the rollers prevents scratches on the transported items.

- ・ Plastic Rollers are attached to the chain pitch line, so the spacing of Plastic Rollers does not change even when the chain is bent.

- For straight running

- For curved transport

- Snap Top Chain

- Gripper Chain

- Accumulation Chain

- Plastic Crescent Chain

- Plastic Roller Table

Accumulation chain list

- チェーンピッチ

38.1mm - For straight running

Please click here for details.

- - The rolling of the rollers prevents scratches on the transported items.

- - Ideal for applications involving accumulation where you want to reduce scratches on the bottom of the transported items and line pressure.

- - Rolling friction coefficient between Plastic Roller and conveyed object: 0.10

Top plate width mm

190.5, 254.0, 304.8

- チェーンピッチ

38.1mm - For curved transport

Please click here for details.

- - The rolling of the rollers prevents scratches on the transported items.

- - Ideal for applications involving accumulation where you want to reduce scratches on the bottom of the transported items and line pressure.

- - Rolling friction coefficient between Plastic Roller and conveyed object: 0.10

Top plate width mm

95.3, 190.5

- チェーンピッチ

38.1mm - For curved transport

- - The rolling of the rollers prevents scratches on the transported items.

- - Ideal for applications involving accumulation where you want to reduce scratches on the bottom of the transported items and line pressure.

- - By increasing the roller diameter from Φ9.5 to Φ11, the gap between the rollers is narrowed, preventing the transported items from getting caught.

- - Coefficient of rolling friction between Plastic Roller and conveyed object: 0.07

Top plate width mm

95.3

- チェーンピッチ

30mm - For curved transport

- - The rolling of the rollers prevents scratches on the transported items.

- - Ideal for applications involving accumulation where you want to reduce scratches on the bottom of the transported items and line pressure.

- - Coefficient of rolling friction between Plastic Roller and conveyed object: 0.07

Top plate width mm

80

- チェーンピッチ

36mm - For curved transport

- - The rolling of the rollers prevents scratches on the transported items.

- - Ideal for applications involving accumulation where you want to reduce scratches on the bottom of the transported items and line pressure.

- - Coefficient of rolling friction between Plastic Roller and conveyed object: 0.07

Top plate width mm

120