Product Info: Linear Actuator

Tsubaki's linear actuator include a lineup of electric cylinders and jacks that use high-quality screws manufactured in-house, as well as our proprietary Zip Chain Zip Chain Actuator.

Both the screw mechanism and Zip Chain mechanism make the most of the product's features and can be used for a wide range of applications, including high-speed, high-frequency operation and operation requiring high precision.

* Zip Chain mechanism is our proprietary technology in which two chains interlock like a zipper to form a single, strong pillar that can be used for both pushing and pulling.

Table of contents

linear actuator related information

-

Selection

-

Materials

-

Operation

Linear motion mechanism type

Zip Chain Mechanism

- High speed

- High frequency

- High durability

- compact

This mechanism uses Tsubaki's proprietary technology, "Zip Chain."

It is highly compact and has the high speed, high frequency and durability required for high tact operation.

By interlocking two chains together to form one rod, it is possible to push and pull.

It was named Zip Chain because it interlocks like a zipper.

(Click here for the special website for the Zip Chain mechanism)

Ball screw mechanism/ Trapezoidal Screw mechanism

- High frequency

- Maximum allowable load

- Quietness

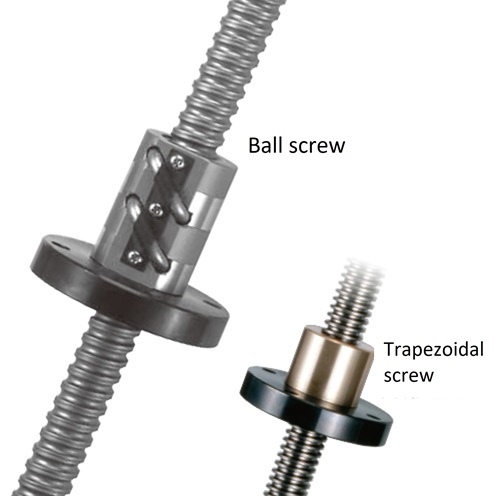

Ball screw mechanism

This mechanism uses steel balls placed between the screw shaft and nut to create rolling friction, allowing for highly efficient operation.

Compared to Trapezoidal Screw mechanisms, it is suitable for high-speed, high-frequency applications, making it suitable for assembly lines where productivity is required.

In addition, its high efficiency allows the drive source to be made smaller.

As we use highly reliable Ball screw manufactured in-house, it is possible to predict the running life.

Ball screw screw with a longer lead per rotation than a regular Ball screw is called a high-lead Ball screw, and can achieve higher speeds even with the same input rotation speed as a regular Ball screw.

Trapezoidal Screw mechanism

This mechanism works by the sliding friction between the screw shaft and nut, and is suitable for low-speed, low-frequency operation such as for maintenance purposes.

It has a self-locking property that Ball screw mechanisms do not have, making it possible to hold loads.

In addition, its simple structure makes it economical.

Tsubaki's linear actuator Product Line

| Electric cylinder: Power Cylinder | Screw jack: Linipower Jack |

Ball screw lifting unit: Linispeed Jack |

Interlocking chain actuator: Zip Chain Actuator |

||

|---|---|---|---|---|---|

|

|

|

|

||

| Mechanism Type | Ball screw Trapezoidal Screw |

Ball screw High Lead Ball screw |

Trapezoidal Screw | Ball screw | Zip Chain |

| the purpose | Pushing and pulling loads | Pushing and pulling loads | Load retention | Pushing and pulling loads | Pushing and pulling loads |

| Features | Motor integrated for easy wiring Realizing a clean environment |

Various screw types available | High Speed/High Frequency, Low Profile, Long Life | High speed and frequency that surpasses other mechanisms, Low profile, long life |

|

| Thrust | Max 490kN | 4.90kN~980kN | 1.96kN~980kN | 15kN~50kN | 400N~2000N |

| Stroke | Maximum 2000mm | Maximum 2000mm | Maximum 1500mm | Maximum 2000mm | |

| Speed and Operating Frequency | Maximum speed: 333mm/s Percentage duty cycle: 50%ED *1 |

Maximum screw shaft speed: 50 to 120 mm/s *2 Allowable Percentage duty cycle: 30%ED |

Maximum screw shaft speed: 40mm/s Allowable Percentage duty cycle: 20%ED |

Maximum screw shaft speed: 200mm/s Allowable Percentage duty cycle: 100%ED *3 |

Maximum speed: 1000mm/s Percentage duty cycle: 100%ED |

| Application example |

Tilting device

Stopper |

Table lift

Rolling Mill |

traverser 's

Take-out |

Stacking and unstacking

Pallet |

|

- *1 Eco series servo type

- *2 Varies depending on screw type

- *3 Varies depending on conditions.

Linear Actuator Product List

An innovative drive unit that achieves high-speed, high-frequency operation and low profiles

Linispeed Jack is an innovative Ball screw unit optimized for servo motor drive.

Normally, lifting mechanisms using Ball screw require the separate procurement and assembly of related parts such as reducers and Ball screw.

With Linispeed Jack, all of these components are unitized, which greatly reduces the effort required for selection and installation.

We also have a proven track record of replacing hydraulic and pneumatic cylinders.

Linispeed Jack

Model number SJ~

Ball screw lift unit that maximizes servo motor performance

- ・Reduction of selection and installation man-hours:

Ball screw and reduction unit are compactly unitized, which means fewer components and less time is required for selection and design. If the optional servo motor flange is used, a servo motor coupling is not required. Also, with fewer components, fewer areas require adjustment, making installation easier. - ・Super high speed:

A "constant thrust" has been achieved that allows heavy loads to be transported at high speeds of 200 mm/s without increasing the size. - ・High frequency operation:

High frequency operation of up to 100% ED is now possible.

(*%ED: Percentage of operating time within a certain operating cycle. Therefore, 100%ED = continuous operation possible) - ・Low profile and compact size:

A low profile has been achieved by incorporating the ball nut into the gear case. - ・Long life:

The high-performance Ball screw achieves a much longer running life than conventional products.

Allowable thrust kN

15, 30, 50

Screw type

Special Ball screw

Stroke mm

100~1500