Mini Keeper

- Ultra-compact slipping clutch and brake

- - By using engineering plastic materials throughout, we have achieved an ultra-lightweight and compact design.

- - Fine chemicals are used on the friction surface, achieving a long life, stable slip torque, and accurate torque reproducibility.

- - The easy-to-read torque scale makes it easy to set the torque.

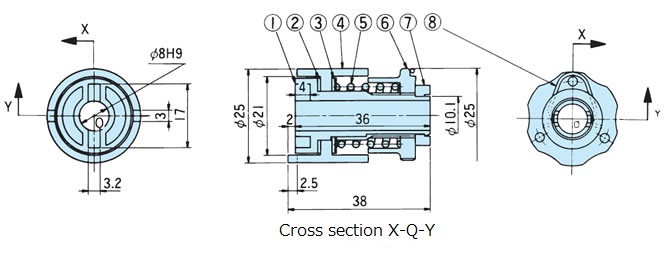

Structure

(1) Hub (2) Friction Plate A (3) Friction Plate B (4) Flange (5) Coil Spring (6) Adjustment Nut (7) Stop Collar

(8) Anti-rotation spring clip

*Dimensions are for MK08.

Specifications (standard model)

| Torque setting range N・cm | Backlash | Reset method |

|---|---|---|

| 1.96~39.2 | None (only when driving in one direction) | Automatic |

(Note) Backlash will occur if the rotation direction is reversed.

Catalogs and Instruction Manuals

Model number display

| MK | 08 |

| | Mini Keeper |

| size (shaft hole diameter mm) |

Product model number list

Selection

When using Mini Keeper in personnel transport or lifting equipment, please take measures on the equipment side to prevent accidents involving personnel or falls.

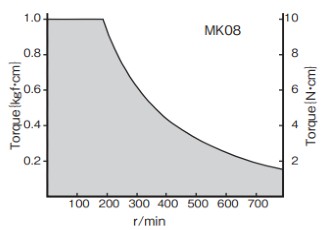

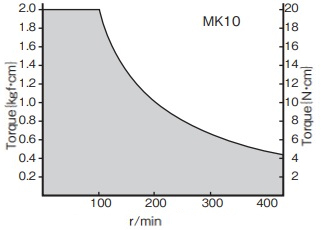

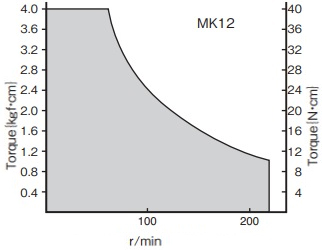

The set torque and slip rotation speed are shown in the TN curve below. Please decide the size so that it fits in the

Please decide the size so that it fits in the

*The TN curve indicates the limit value due to heat generation during continuous slip. If the slip time per slip is short and the interval is long, it is possible to exceed the TN value.

In that case, please contact us.

*Please contact us for non-standard specifications.

*However, please note that if the rotation speed is below 30 r/min, stick-slip may occur and the torque may not be stable.

The stick-slip phenomenon is a phenomenon in which friction surfaces repeatedly stop and slide.

TN curve diagram

The TN curve should be used for ambient temperatures up to 35°C. If this range is exceeded, please contact us.

Torque setting/mounting

Please refer to Instruction Manuals for details.