Power Cylinder Eco series CDS type

- This electric cylinder is ideal for use in two-point operation like an air cylinder. It has a current detection type self-contained function.

- As part of our efforts to address environmental issues, we have developed an environmentally friendly Power Cylinder.

- Not only does it have advantages over air and hydraulic systems, but it also does not use parts that contain harmful substances, making it a more environmentally friendly product than conventional products.

It can be used for a variety of purposes, including replacing air or hydraulic cylinders. - Rated thrust: 250N to 1000kN

- Rated speed: 90-200mm/s

Features

-

・Self-contained

The spring built into the actuator and the CDS (Current Detective System) installed inside the terminal box detect overcurrent when pressing and stopping, or in the unlikely event of an overload, and automatically stop the motor.

When stopped, Pressing force is maintained by the built-in spring. Pressing and stopping is possible at any position within the stroke, and no electrical position command or limit switch is required.CDS: Current Detective System. Detects overcurrent and stops the motor.

-

・Reduced running costs and environmental friendliness

Because it is electrically operated, it consumes electricity only when in use, making it economical. Unlike air systems, there is no need to run a compressor all the time, which significantly reduces running costs.

Furthermore, unlike air and hydraulic systems, there is no need to worry about noise, mist scattering, or oil leakage, and the cylinder is environmentally friendly and complies with the RoHS Directive. -

- High frequency operation - Long life

High frequency operation of up to 15 times per minute is possible. In addition, the use of Ball screw can be expected to have a long life of 1 million strokes.

-

・Easy operation

It can be operated simply by connecting a three-phase power supply. There is no need for a limit switch for stroke adjustment, so there is no need for complicated wiring. Long wiring distances are also possible.

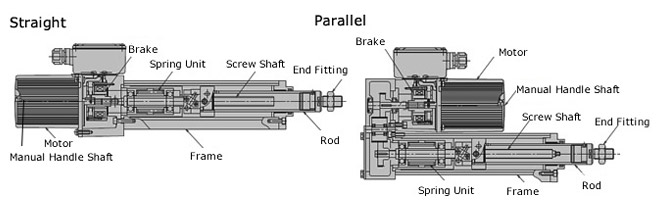

Structure

Standard model list

| Model | speed symbol |

Main unit shape |

Rated thrust N {kgf} |

Nominal speed mm/s 50/60/60Hz |

Motor Output N・m |

stroke mm |

|---|---|---|---|---|---|---|

| LPE025 | H | T or K | 250 {25.5} | 160/190/200 | 0.25 (equivalent to 50W) | 100 200 300 400 500 600 |

| LPE050 | L | 500 {51.0} | 90/100/110 | 0.25 (equivalent to 50W) | ||

| H | 160/170/190 | 0.50 (equivalent to 90W) | ||||

| LPE100 | L | 1.00k {102} | 90/90/110 | 0.50 (equivalent to 90W) |

- * Pressing force varies depending on the model and is 2 to 3 times the rated thrust.

Option List

Back to top of this page

Back to top of this page

Catalogs and Instruction Manuals

Model number display example

| LPE | 100 | L | K | 5 |

| | Series Name |

| Rated thrust |

| Rated speed |

| Body shape |

| stroke |

| Power Cylinder Eco Series |

025: 250N{25.5kgf} 050: 500N{51.0kgf} 100:1000N{102kgf} |

L, H Please refer to the detailed information for actual speeds. |

T: Straight K: Parallel |

1:100mm 2:200mm 3:300mm 4:400mm 5:500mm 6:600mm |

■ Tsubaki model No. navigation

Rated thrust

This is the rated thrust at which the motor can operate.

Rated speed

This is the operating speed when the rated thrust is generated.

Please refer to the detailed information for the speed values of each model.

Body shape

T: A straight shape in which the motor and actuator are arranged in a straight line.

K: A parallel configuration with a gearbox placed between the motor and actuator.

Stroke

The stroke distance of the operating part.

Option symbol

M: The rod is fitted with a rotation stopper.

S: Equipped with a magnetic sensor to detect stroke.

Can be selected as a set with the rod anti-rotation specification.

I: Comes with an I-shaped End fitting.

U: Comes with a U-shaped End fitting.

J: It comes with bellows.

Product model number list

*Click on the model number to display detailed information.

| thrust N {kgf} |

stroke mm |

Speed L | Speed H | ||

|---|---|---|---|---|---|

| Straight type | Parallel type | Straight type | Parallel type | ||

| 250 {25.5} |

100 | --- | --- | LPE025HT1 | LPE025HK1 |

| 200 | LPE025HT2 | LPE025HK2 | |||

| 300 | LPE025HT3 | LPE025HK3 | |||

| 400 | LPE025HT4 | LPE025HK4 | |||

| 500 | LPE025HT5 | LPE025HK5 | |||

| 600 | LPE025HT6 | LPE025HK6 | |||

| 500 {51.0} |

100 | LPE050LT1 | LPE050LK1 | LPE050HT1 | LPE050HK1 |

| 200 | LPE050LT2 | LPE050LK2 | LPE050HT2 | LPE050HK2 | |

| 300 | LPE050LT3 | LPE050LK3 | LPE050HT3 | LPE050HK3 | |

| 400 | LPE050LT4 | LPE050LK4 | LPE050HT4 | LPE050HK4 | |

| 500 | LPE050LT5 | LPE050LK5 | LPE050HT5 | LPE050HK5 | |

| 600 | LPE050LT6 | LPE050LK6 | LPE050HT6 | LPE050HK6 | |

| 1000 {102} |

100 | LPE100LT1 | LPE100LK1 | --- | --- |

| 200 | LPE100LT2 | LPE100LK2 | |||

| 300 | LPE100LT3 | LPE100LK3 | |||

| 400 | LPE100LT4 | LPE100LK4 | |||

| 500 | LPE100LT5 | LPE100LK5 | |||

| 600 | LPE100LT6 | LPE100LK6 | |||

Special support

・Special support is available to suit your usage conditions.