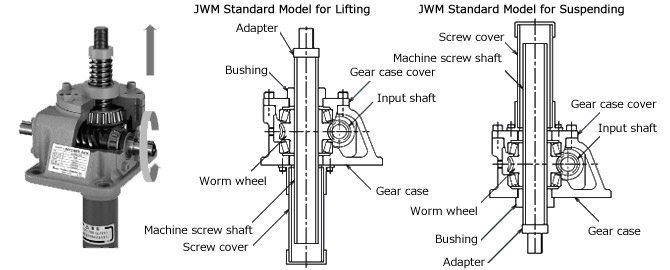

Linipower Jack JWM (Trapezoidal Screw Type)

- JWM (Trapezoidal Screw type) is a general-purpose, low-noise screw jack.

- The main components are a concentric Trapezoidal Screw and a high-precision worm gear.

- Simple, compact structure and economical. Load retention is expected. (Self-locking)

- Left-handed and stainless steel screw specifications are also available.

Features

-

Economical

Its simple and compact structure makes it economical.

-

・Low noise

It uses Trapezoidal Screw with sliding contact, making it ideal for applications where noise is a problem.

-

・Load retention

Trapezoidal Screw are calculated to have self-locking properties, and can be expected to retain load.

*The self-locking mechanism may become ineffective due to vibration, shock, etc. In such cases, a brake device is required.

-

-Trapezoidal Screw type, stainless steel screw specifications

For the two models JWM025 and JWM050, austenitic stainless steel screw shafts are now available.

Ideal for devices that require rust prevention on screw shafts, water gates and various gate opening and closing devices, environmental equipment, paper manufacturing machines, etc.

-

-Trapezoidal Screw type, left-hand screw specification

The input rotation direction is the same, but the screw moves in the opposite direction to the right-hand screw specification. When using multiple jacks driven by one motor, or when the input rotation direction is not the same due to the installation of the jacks

However, this can be easily solved if there is a left-handed thread specification.

Basic specification structure

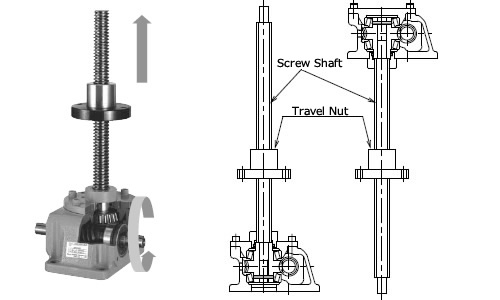

Traveling nut structure

Standard model list

・Basic capacity

| Frame No. | Basic capacity kN {tf} | Worm reduction ratio | |

|---|---|---|---|

| H | L | ||

| 002 | 1.96 {0.2} | 5 | 20 |

| 005 | 4.90 {0.5} | 5 | 20 |

| 010 | 9.80 {1} | 5 | 20 |

| 025 | 24.5 {2.5} | 6 | 24 |

| 050 | 49.0 {5} | 6 | 24 |

| 100 | 98.0 {10} | 8 | 24 |

| 150 | 147 {15} | 8 | 24 |

| 200 | 196 {20} | 8 | 24 |

| 300 | 294 {30} | 10 2/3 | 32 |

| 500 | 490 {50} | 10 2/3 | 32 |

| 750 | 735 {75} | 10 2/3 | 32 |

| 1000 | 980 {100} | 12 | 30 |

·Stroke

| Frame No. | 2 | 5 | 10 | 25 | 50 | 100 | 150 | 200 | 300 | 500 | 750 | 1000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 200 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 300 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 400 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 500 | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 600 | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 800 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 1000 | - | △ | ○ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 1200 | - | - | △ | ○ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 1500 | - | - | - | △ | ○ | ○ | ○ | ○ | △ | △ | △ | △ |

| 2000 | - | - | - | - | △ | △ | △ | ○ | △ | △ | △ | △ |

- ○: Standard product, △: Made to order, - marks are manufactured according to the conditions of use. Please contact us for details.

- Traveling nut specifications for frame numbers JWM300 and above will be manufactured on a case-by-case basis.

- *Conditions of use must be confirmed when manufacturing JWM750 and 1000 types.

Catalogs and Instruction Manuals

Model number display example

| JW | M | 050 | U | S | H | 10 | U |

| | Series Name Linipower jack |

| | | | | | | | | | | | |

| Basic capacity 002: 1.96kN{0.2tf} 005: 4.90kN{0.5tf} 010: 9.80kN{1tf} 025: 24.5kN{2.5tf} 050: 49.0kN{5tf} 100: 98.0kN{10tf} 150: 147kN{15tf} 200: 196kN{20tf} |

| | | | | | | | | | | | |

| | | | | | | |

| Worm reduction ratio L, H For the actual reduction ratio, please refer to the detailed information. |

| Nominal stroke 1: 100mm 2: 200mm 3: 300mm 4: 400mm 5: 500mm 6: 600mm 8: 800mm 10: 1000mm 12: 1200mm 15: 1500mm 20: 2000mm |

| Flange mounting direction *Notation required only for traveling nut specifications. |

| Screw specifications S: Basic form M: Anti-rotation specification R: Traveling nut specification |

|||||||

| Screw Type M: Trapezoidal Screw |

Mounting Shape U: For pushing up D: For hanging |

||||||

■ Tsubaki model No. navigation

Screw Type

M: Trapezoidal Screw type.

B: Ball screw type.

H: High lead Ball screw type.

Basic capacity

This is the basic capacity that the jack body can handle.

Mounting Shape

U: This type has a screw shaft on the opposite side of the main body mounting base.

D: This type has a screw shaft protruding from the main body mounting base side.

Screw specifications

S: This is the basic form in which the screw shaft moves.

M: The basic form in which the screw shaft moves.

The screw shaft has an anti-rotation function.

R: The screw shaft rotates and the nut moves.

Worm reduction ratio

Reduction ratio of the worm reducer.

Please refer to the detailed information for the reduction ratio values of each model.

Stroke

travel distance of the threaded shaft or traveling nut.

Flange mounting direction

For traveling nut types, specify which side of the nut the mounting flange should be on.

U: Upper side

D: Lower side

Option symbol

J: It comes with bellows.

B: Comes with End fitting of the rod.

I: Equipped with I-type end fitting.

M: Comes with table-shaped End fitting.

C: Equipped with clevis.

Y: A limit switch with a mechanical counter.

K2: Two built-in microswitches detect the stroke position.

K4: Equipped with four built-in microswitches that detect the stroke position.

P: Equipped with a potentiometer that detects the stroke position.

R: Equipped with a rotary encoder that outputs a stroke movement signal.

E: Comes with a three-phase brake motor.

The power supply supports 200/200/220V 50/60/60Hz.

EV: Comes with a three-phase motor with brake.

The power supply supports 400/400/440V 50/60/60Hz.

G1: Equipped with a three-phase gear motor with brake, the reduction ratio is 1/5.

The power supply supports 200/200/220V 50/60/60Hz.

G2: Equipped with a three-phase gear motor with brake, the reduction ratio is 1/10.

The power supply supports 200/200/220V 50/60/60Hz.

Product model number list

*Click on the model number to display detailed information. Open all Close all

Basic capacity 1.96kN {0.2tf} (model number JWM002~)

Basic capacity 1.96kN {0.2tf} (model number JWM002~)

| Mounting Shape | stroke mm |

For pushing up Worm speed ratio: H |

For pushing up Worm speed ratio: L |

For hanging Worm speed ratio: H |

For hanging Worm speed ratio: L |

|---|---|---|---|---|---|

| Basic form | 100 | JWM002USH1 | JWM002USL1 | JWM002DSH1 | JWM002DSL1 |

| 200 | JWM002USH2 | JWM002USL2 | JWM002DSH2 | JWM002DSL2 | |

| 300 | JWM002USH3 | JWM002USL3 | JWM002DSH3 | JWM002DSL3 | |

| 400 | JWM002USH4 | JWM002USL4 | JWM002DSH4 | JWM002DSL4 | |

| Anti-rotation specification | 100 | JWM002UMH1 | JWM002UML1 | JWM002DMH1 | JWM002DML1 |

| 200 | JWM002UMH2 | JWM002UML2 | JWM002DMH2 | JWM002DML2 | |

| 300 | JWM002UMH3 | JWM002UML3 | JWM002DMH3 | JWM002DML3 | |

| 400 | JWM002UMH4 | JWM002UML4 | JWM002DMH4 | JWM002DML4 | |

| Traveling nut type | 100 | JWM002URH1U JWM002URH1D |

JWM002URL1U JWM002URL1D |

JWM002DRH1U JWM002DRH1D |

JWM002DRL1U JWM002DRL1D |

| 200 | JWM002URH2U JWM002URH2D |

JWM002URL2U JWM002URL2D |

JWM002DRH2U JWM002DRH2D |

JWM002DRL2U JWM002DRL2D |

|

| 300 | JWM002URH3U JWM002URH3D |

JWM002URL3U JWM002URL3D |

JWM002DRH3U JWM002DRH3D |

JWM002DRL3U JWM002DRL3D |

|

| 400 | JWM002URH4U JWM002URH4D |

JWM002URL4U JWM002URL4D |

JWM002DRH4U JWM002DRH4D |

JWM002DRL4U JWM002DRL4D |

Basic capacity 4.90kN {0.5tf} (model number JWM005~)

Basic capacity 4.90kN {0.5tf} (model number JWM005~)

Basic capacity 9.80kN {1tf} (model number JWM010~)

Basic capacity 9.80kN {1tf} (model number JWM010~)

Basic capacity 24.5kN {2.5tf} (model number JWM025~)

Basic capacity 24.5kN {2.5tf} (model number JWM025~)

Basic capacity 49.0kN {5tf} (model number JWM050~)

Basic capacity 49.0kN {5tf} (model number JWM050~)

Basic capacity 98.0kN {10tf} (model number JWM100~)

Basic capacity 98.0kN {10tf} (model number JWM100~)

Basic capacity 147kN {15tf} (model number JWM150~)

Basic capacity 147kN {15tf} (model number JWM150~)

Basic capacity 196kN {20tf} (model number JWM200~)

Basic capacity 196kN {20tf} (model number JWM200~)

Special support

・Special support is available to suit your usage conditions.