Large Conveyor Sprocket Fit bore

- This sprocket is designed specifically for Large size conveyor chain.

- Fit Bore is a finished product with a finished shaft hole.

- You can use it immediately after delivery.

- The processing details are coded, so you can easily order just by entering the model number.

Features

- - The details of shaft hole processing and keyway processing are coded in the product name, so the customer's order details can be communicated accurately.

- - The shaft hole, keyway, tapped hole, etc. are already processed, so the product can be used as is after it arrives to the customer.

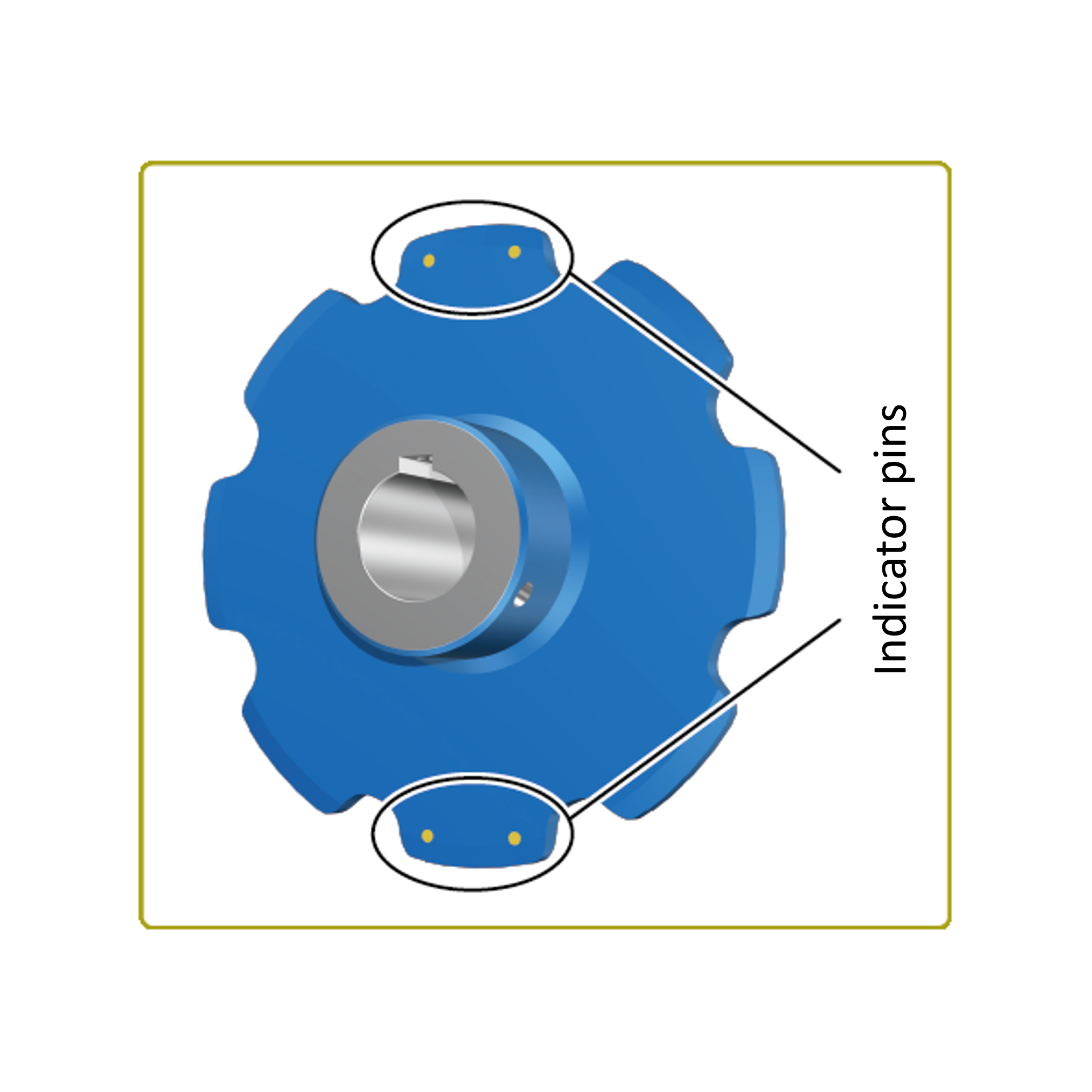

- -You can choose Indicator pins option, which allows you to see at a glance the limit of tooth use.

Catalogs and Instruction Manuals

Model number display example

| RF17200S12T-BW1 | Q | - | H | 090 | N | - | J | 25 | D3 | M16 | - | H1 | - | L2 | -E | |

| | Main unit model number |

| | | | |

| Shaft bore tolerance H:H8 |

| | | | | | | |

| Shaft bore chamfer N: Tsubaki standard A: C1 B: C2 C: C3 |

| | | | |

| Keyway tolerance |

| | | | |

| Tap Size |

| Parallel symbols (2) |

| Paint Code (3) |

| | | | |

|||||

| Tooth tip hardening N: No tooth tip hardening Q: Hardened teeth |

Keyway tolerance W: No keyway J: New JIS Js9 P: New JIS P9 E: Old JIS E9 |

Tap hole machining package (1) |

Indicator pins No markings: None E: Indicator pins |

|||||||||||||

| Shaft Bore Diameter mm |

||||||||||||||||

| (1) Tap hole machining package | (2) Parallel symbols *Set of two | |||||

|---|---|---|---|---|---|---|

* Tap arrangement for H1 and H3 in parallel use is |

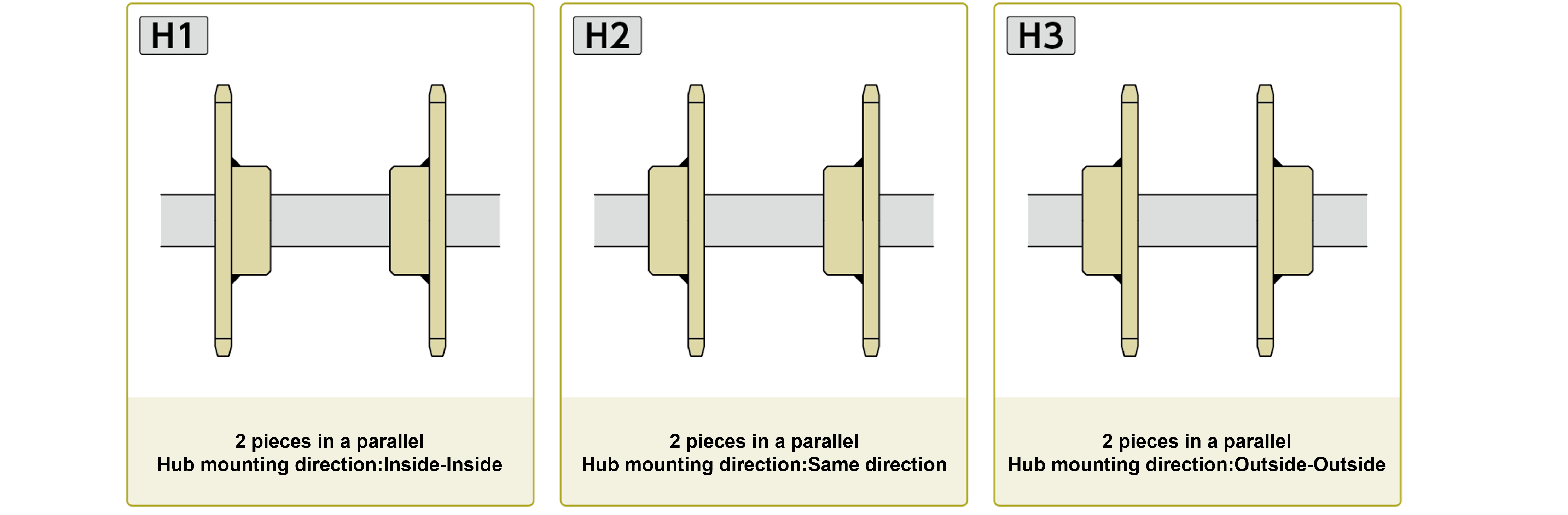

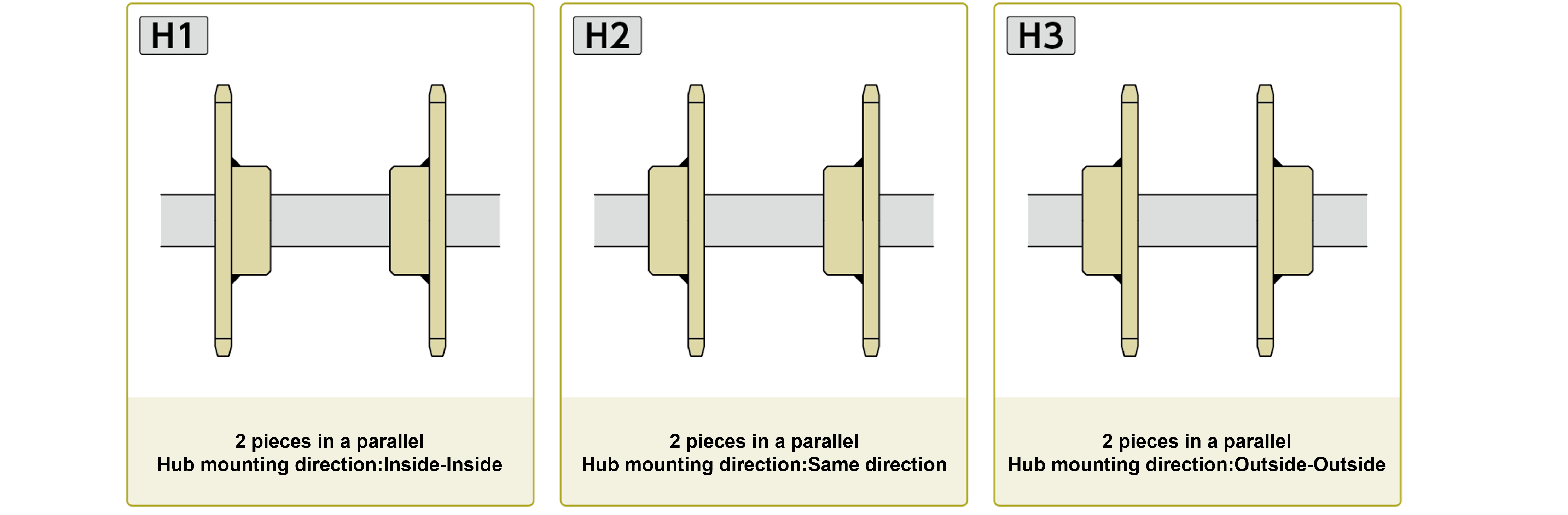

Hub installation direction image

*For H1 and H3, half-assembled in mirror image, Mirror Image. half-assembled in mirror image, Mirror Image For general sprockets used in parallel, the tap arrangement is machined symmetrically. Example: For D2M16-H1-L0

|

|||||

| (3) Paint code | ||||||

|

Product List

Metric pitch

| Model number | R Roller | F Roller | S Roller | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of teeth | Number of teeth | Number of teeth | ||||||||||

| 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | |

| RF03075 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF03100 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF05075 | - | - | - | - | - | - | - | - | - | ● | ● | ● |

| RF05100 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF05125 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF05150 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF08125 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF08150 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF10100 | ● | ● | ● | ● | - | - | - | - | ● | ● | ● | ● |

| RF10125 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF10150 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF12200 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF12250 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF17200 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF17250 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF17300 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Inch pitch

| Model number | R Roller | F Roller | S Roller | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of teeth | Number of teeth | Number of teeth | ||||||||||

| 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | |

| RF430 | ● | ● | ● | ● | - | - | - | - | ● | ● | ● | ● |

| RF204 | - | - | - | - | - | - | - | - | - | ● | ● | ● |

| RF450 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF650 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF214 | ● | ● | ● | ● | - | - | - | - | ● | ● | ● | ● |

| RF205 | - | - | - | - | - | - | - | - | - | ● | ● | ● |

| RF6205 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| RF212 | ● | ● | ● | ● | - | - | - | - | ● | ● | ● | ● |

Machining contents

*Click to display detailed information.

| Shaft hole processing (L) | Keyway processing (K) | Tap hole processing (D) |

|---|---|---|

|

|

|

|

・Processing dimensions are integers in 1mm increments only ・Processing tolerance: H8 only |

・Parallel keyway only ・Processing tolerance...selectable |

・Processing size can be selected ・You can select up to two processing locations -Hex socket set screw included (recessed tip) |

Shaft hole machining dimensions list

Shaft hole machining dimensions list

In the case of JS9/P9 (new JIS)

| Applicable shaft hole diameter (mm) |

Keyway width (mm) |

Tap Size (Tsubaki standard) |

Selected size |

|---|---|---|---|

| 19~22 | 6 | M6 | M5 |

| 22~30 | 8 | M6 | M5, M8 |

| 30~38 | 10 | M8 | M6, M10 |

| 38~44 | 12 | M8 | M6, M10 |

| 44~50 | 14 | M8 | M6, M10 |

| 50~58 | 16 | M10 | M8, M12 |

| 58~65 | 18 | M10 | M8, M12 |

| 65~75 | 20 | M12 | M10, M16 |

| 75~85 | 22 | M12 | M10, M16 |

| 85~95 | 25 | M16 | M12, M20 |

| 95~110 | 28 | M16 | M12, M20 |

| 110~130 | 32 | M20 | M16 |

| 130~150 | 36 | M20 | M16 |

| 150~170 | 40 | M20 | M16 |

| 170~175 | 45 | M24 | M20 |

In the case of E9 (old JIS)

| Applicable shaft hole diameter (mm) |

Keyway width (mm) |

Tap Size Tsubaki Standard |

Selected size |

|---|---|---|---|

| 19~20 | 5 | M5 | M4 |

| 21~30 | 7 | M6 | M5 |

| 31~40 | 10 | M8 | M6, M10 |

| 41~50 | 12 | M8 | M6, M10 |

| 51~60 | 15 | M8 | M6, M10 |

| 61~70 | 18 | M10 | M8, M12 |

| 71~80 | 20 | M12 | M10, M16 |

| 81~95 | 24 | M12 | M10, M16 |

| 96~110 | 28 | M16 | M12, M20 |

| 111~125 | 32 | M20 | M16 |

| 126~140 | 35 | M20 | M16 |

| 141~160 | 38 | M20 | M16 |

| 161~175 | 42 | M20 | M16 |

Tsubaki standard shaft hole chamfer

Tsubaki standard shaft hole chamfer

| Applicable shaft hole diameter (mm) | Chamfer |

|---|---|

| ~50 | C0.6 |

| 51~80 | C1 |

| 81~120 | C1.6 |

| 121~175 | C2 |

| Shaft Hole Diameter | Selectable chamfer amount | |||

|---|---|---|---|---|

| ~44 | N | A | B | - |

| 45~ | N | A | B | C |

| H0 | None |

| H1 | Hub installation direction: Inner-inner |

| H2 | Hub installation direction: Same direction |

| H3 | Hub mounting direction: Outer-outer |

- - For parallel use, when two sprockets are used on the same axis, the keyway position is aligned in the specified installation direction.

- - Please select the hub mounting direction from the three patterns shown in the diagram below.

Hub installation direction image

| L0 | No paint (rust prevention oil applied) |

| L1 | Lacquer paint (standard paint color) |

| L2 | Lacquer paint (Indicator pins paint color) |

・If Indicator pins specification is painted, L2 will be blue.

| E | Indicator pins |

| Anonymous | None |

- - Brass pin embedded specification.

- - Embed into two teeth on each side of the sprocket tooth section, aiming for 0 degrees and 180 degrees.

If keyway processing is available, one is embedded in the tooth above the keyway

others

| Limitations | Please contact us for inspection report and material certificate. (If submission is required, it will be treated as a general special form.) |

|---|