Lift Master Ball Screw Type

- Cantilever lifter using a Ball screw screw

- - High efficiency and high speed

The use of Ball screw makes it possible to obtain a large thrust with a small drive source with high efficiency.

Its high efficiency allows for easier high-speed operation of the device compared to Trapezoidal Screw. - ・Operation precision and controllability

It is also compatible with servo motor drive, allowing for multi-point position control and multiple synchronized operations. - ・Long lifespan

Highly reliable Ball screw are used, allowing for predictable running life and ensuring a long service life. - ・A wide variety of options

It is also possible to perform complex movements such as rotating Lift Master and tilting the arm.

Features and structure Video content

Benefits of hiring

- ・You can freely layout your production line >>Learn more

- ・Easy to use >>More details

- ・Improved working environment >>Learn more

- ・Energy saving effect >>Learn more

Specifications (Ball screw type)

- ・Lifting load: 1.96kN to 9.80kN

- ・Stroke: 400mm/1,500mm

- ・Drive unit: with three-phase motor/servo motor

- ・Speed: 1.5-9.96m/min

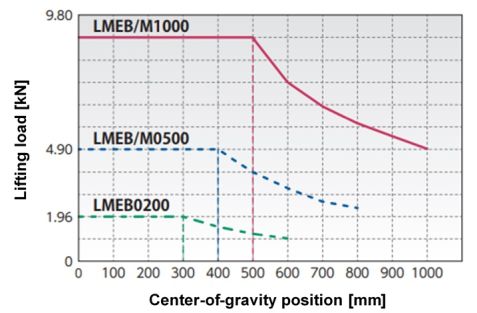

Allowable OHL load curve (based on workpiece mounting surface: see outline drawing)

Catalogs and Instruction Manuals

For a comparison of Zip Chain mechanism and the screw mechanism, please see here.

Model number display

| LME | B | 0500 | H | 10 | G | E |

| | | Lift Master |

| Screw type B: Ball screw |

| Lifting load 0200: 1.96kN {200kgf} 0500: 4.90kN{500kgf} 1000: 9.80kN {1000kgf} |

| speed S, H, U The speed of each model More information Please refer to. |

| stroke 04: 400mm 06: 600mm 08: 800mm 10: 1000mm 12: 1200mm 15: 1500mm |

| Drive unit G: With three-phase motor K: With servo motor |

| option See below for details |

Product model number navigation

What type of screws are used?

Lifting load

This is the load that can be raised or lowered at the specified center of gravity.

speed

This symbol indicates the lifting speed.

Please refer to the detailed information for the speed values of each model.

Stroke

The distance that can be raised or lowered.

Drive unit

G: Comes with a three-phase motor.

K: It comes with a servo motor.

Option symbol

J: Bellows are attached to the opening.

L1 to L3: Add one to three position detection sensors.

V: This specifies the power supply voltage will be doubled.

E: A rotary encoder is attached to the rear of the motor.

D1 to D3: Change the motor mounting direction.

D1: 90° rotation from the standard position

D2: 180° rotation from the standard installation position

D3: 270° rotation from the standard mounting position

Product model number list

*Click on the model number to display detailed information.

option

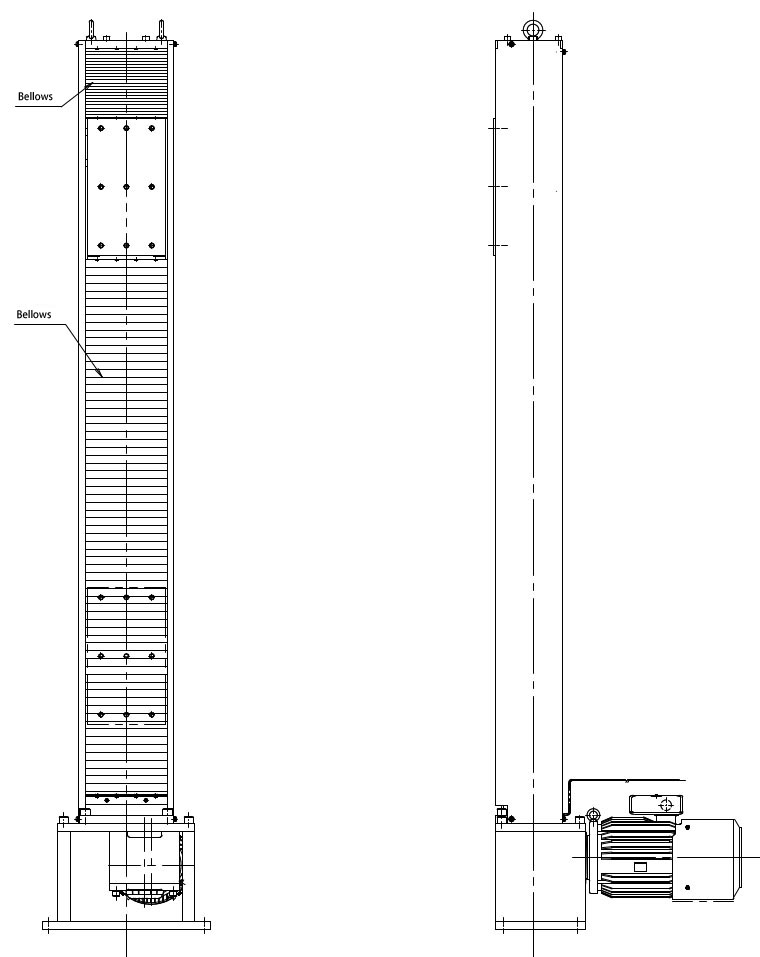

Front bellows [option code: J]

- Bellows to prevent dust from entering Lift Master from the front.

Supported stroke: 400mm to 1,200mm

*Please contact us if you require bellows mounting for strokes exceeding 1,200 mm.

*Only for LME0200 series and LME0500 series with strokes of 800mm and 1,200mm.

The effective stroke will be shorter when the front bellows is installed. Please contact us for details.

<Installation reference example>

Please contact us for dimensions.

[Click to enlarge]

Add a position detection sensor [option code: L1 to L3]

・The standard model is equipped with four position detection sensors (two for S-speed only),

Up to three sensors are available for S speed only, and one additional sensor is available for other speeds.

・The option symbol is [L1] for adding one sensor, [L2] for adding two sensors, and [L3] for adding three sensors.

If you would like to add more sensors, please contact us.

Compatible model number L1: All standard model numbers

L2, L3: LMEB0200S, LMEM0500S, LMEM1000S only

Motor voltage 400V class [option code: V]

・Change the drive motor voltage to 400V class.

Compatible models: All standard models

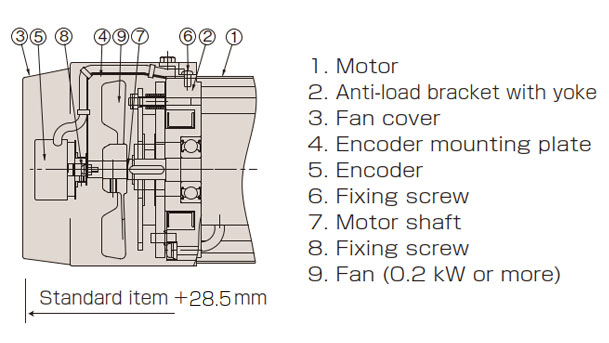

With rotary encoder [Option code: E]

- A rotary encoder can be installed on the shaft end of the non-load side of a three-phase motor, enabling the motor rotation signal to be output.

Compatible model: Standard model with three-phase motor

Features

・Controllability

An open collector output signal can be extracted from the reducer, allowing for a variety of operations.

·compact

There is no need to connect the motor shaft and rotary encoder with a coupling.

・Cost reduction

Compared to conventional separate installations, there is no need for couplings, base plates, or leveling work.

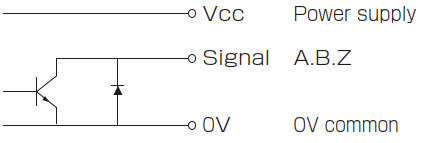

Rotary encoder specifications

| Power supply voltage | DC4.5~30V |

|---|---|

| Number of pulses | 100 |

| Output format | Open collector output (NPN type) 6 AB90° phase difference signal +Z origin signal |

| Output Circuit | |

| Current consumption | 30mA or less |

| Output Voltage | 0.5V or less (At maximum sink current) |

| Maximum sink current | 40mA MAX |

| Signal rising Fall time |

1μs or less |

| Maximum Response Frequency | 240kHz |

| Output circuit withstand voltage | 50V MAX |

| Cable length | 0.5m with connector (Hirose Electric Co., Ltd. DF3-6S-2C) |

| vibration | 4.9m/s 2 {0.5G} or less (20~50Hz) |

Structure and dimensions (rotary encoder mounting part)

Wiring Table

| Pin No. | color | connection |

|---|---|---|

| 1 | red | power supply |

| 2 | black | 0V common |

| 3 | blue | Signal A |

| 4 | white | Signal B |

| 5 | yellow | Signal Z |

| 6 | black | shield |

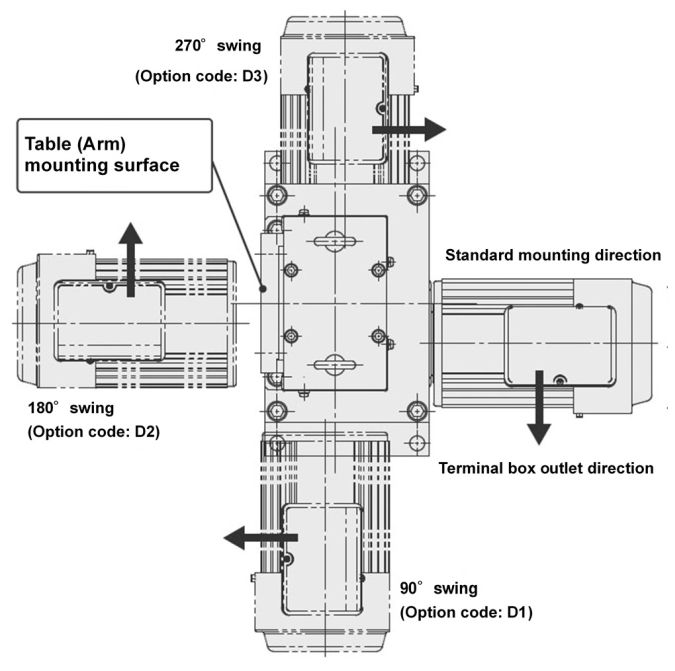

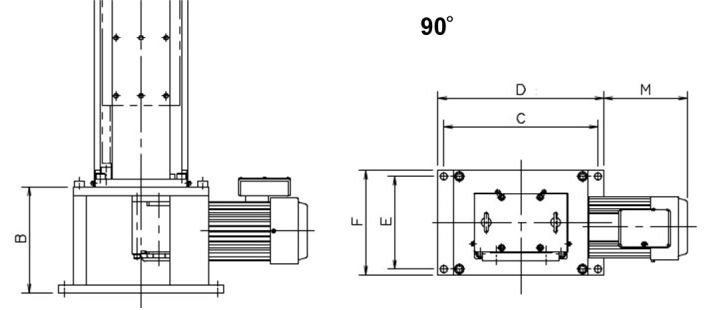

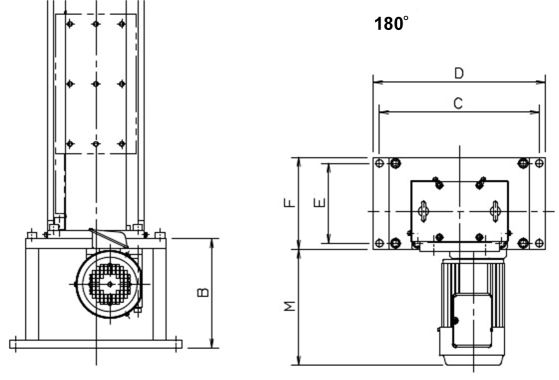

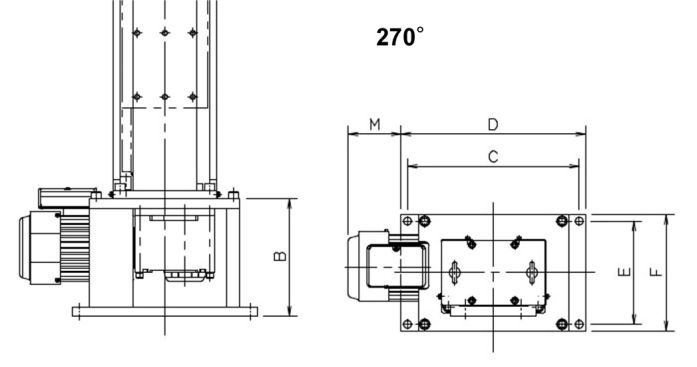

Motor mounting direction change [Option code: D1 to D3]

- The motor installation direction can be changed depending on the installation location of the equipment, the workpiece installation, the transfer direction of the transported items, etc.

*The overall height may change depending on the motor installation direction and stroke.

*The LME0200S series has the motor attached to the top, so the contact area with the floor is the same as the standard product regardless of the orientation.

Please contact us regarding the dimensions of the motor and flange that protrude from the guide.

*The drawings and dimensions below show the specifications for a three-phase motor. Servo motors are also available as an option, so please contact us for details.

Compatible models: All standard models

D1: Motor installation direction changed by 90 degrees

D2: Motor installation direction changed 180 degrees

D3: Motor installation direction changed 270 degrees

| D1: 90 degree offset | D2: 180 degree offset | D3: 270 degree offset |

|---|---|---|

|

[Click to enlarge] |

[Click to enlarge] |

[Click to enlarge] |

<D1 Dimension Comparison Table>

<D1 Dimension Comparison Table>

| Model | Motor Capacity kW |

Standard motor mounting direction | D1: 90 degree offset | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 154 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 190 | 220 | 160 | ||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 270 | 210 | 240 | 237 | |||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 318 | 400 | 430 | 255 | 285 | 283 |

| 1000S | 0.75 | 250 | 273 | 240 | 270 | 217 | |||||||

| 1000H | 1.5 | 368.5 | 318 | 255 | 285 | 293 | |||||||

| 1000U | 2.2 | 407 | 343 | ||||||||||

<D2 dimension comparison table>

<D2 dimension comparison table>

| Model | Motor Capacity kW |

Standard motor mounting direction | D2: 180 degree offset | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 172 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 223 | ||||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 265 | 300 | |||||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 273 | 400 | 430 | 200 | 230 | 366 |

| 1000S | 0.75 | 250 | 290 | ||||||||||

| 1000H | 1.5 | 368.5 | 366 | ||||||||||

| 1000U | 2.2 | 407 | 416 | ||||||||||

<D3 Dimension Comparison Table>

<D3 Dimension Comparison Table>

| Model | Motor Capacity kW |

Standard motor mounting direction | D3: 270 degree offset | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | E | F | M | B | C | D | E | F | M | ||

| 0200S | 0.1 | - | 250 | 280 | 170 | 200 | 141 | - | 250 | 280 | 170 | 200 | 80 |

| 0200H | 0.4 | 245 | 340 | 370 | 193 | 245 | 340 | 370 | 190 | 220 | 86 | ||

| 0500S | 0.4 | ||||||||||||

| 0500H | 0.75 | 270 | 270 | 210 | 240 | 163 | |||||||

| 0500U | 1.5 | 273 | 400 | 430 | 200 | 230 | 369 | 318 | 400 | 430 | 255 | 285 | 209 |

| 1000S | 0.75 | 250 | 273 | 240 | 270 | 123 | |||||||

| 1000H | 1.5 | 368.5 | 318 | 255 | 285 | 199 | |||||||

| 1000U | 2.2 | 407 | 249 | ||||||||||

Selection

Our staff will select the lifter that meets your requirements and requirements.

Please click on the "sizing" tab at the top of this page.

Special specification products

Wall mounting specifications

If Lift Master cannot be installed on the floor, it can also be mounted on a wall, making effective use of the sturdy side of the device frame to save space.

Fall prevention specifications

A manual fall prevention pin can be attached to Lift Master to prevent it from falling.

Swivel axis specifications

A manual rotation mechanism is provided at the workpiece mounting section.

Low-profile specification

Even if you cannot install Lift Master due to space limitations, we can accommodate you with a reduced height specification.

High-speed specifications

This is a high-speed specification with a maximum speed of 500 mm/s. Please provide a servo motor. Please contact us for details. *High-speed specifications up to 300 mm/sec can be operated with a general-purpose motor using inverter control.

Dustproof and waterproof

Lift Master is dustproof and drip-proof. It can also be used in environments where cutting oil and coolant are present. *Not suitable for outdoor use.

Horizontal Transfer Mechanism

We can also manufacture Lift Master for horizontal transport.

High rigidity specifications

If shaking during lifting or bending when stopped is an issue, we can address this by strengthening the support pillar itself.

Line shaft synchronous type

Lift Master can be connected to Tsubaki's ECHT-FLEX coupling and Miter Gear Box to enable synchronized operation. We provide a system that matches your usage conditions, including Gear Motor.