Pin gear drive Unit

- Proposing cost reduction for rotary and linear drives

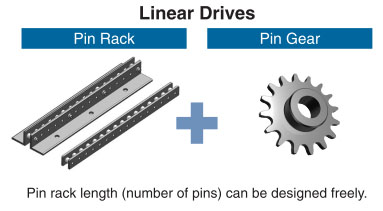

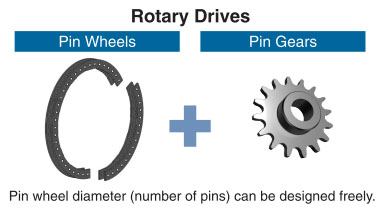

- Pin gear drive is a new drive unit that replaces gears and racks.

- The combination of a pin-mechanical wheel/rack and a special tooth gear greatly expands the design freedom of the rotary and linear drive parts.

- *Easy installation: The split segment system makes installation easy. It can also be used with rough installation accuracy.

- *Large transmission torque: The pin gear is designed with a generous module, and the good balance with the pin wheel and rack allows for large transmission torque.

- *Can be used in large equipment: By increasing the number of segments, the wheel type can be used in large drive equipment.

- * A lineup of sizes ideal for large equipment in the steel industry, etc.: Achieves cost and tangential force that surpasses large gears.

Catalogs and Instruction Manuals

composition

Pin gear drive unit is a drive unit that comes with a pin rack (or pin wheel) that meshes with a pin gear.

Features

Easy to install and allows for rough installation.

- - All pins on the pin racks and pin wheels are Hollow Pins for installation, so installation can be easily done using these holes.

Combining segmented units can accommodate large machines.

- - In the case of racks, by aligning the joint surfaces, the pitch intervals between units can be maintained and they can be joined, enabling long linear drives.

- - Pinwheels for large machines are assembled in segments, so by combining segments, large diameter pinwheels can be accommodated.

Compared to the chain system, the transmission force is greater and the size can be reduced.

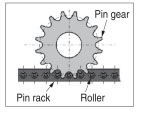

Structure

The pin gear has a special tooth profile that meshes smoothly and continuously with the roller.

The teeth are hardened to improve strength and abrasion resistance.

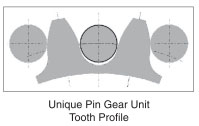

Pin gear dedicated tooth profile

The pin gear tooth profile is based on an approximate involute curve, which enables smooth engagement with the pin rack/wheel, while also using a Tsubaki original tooth profile for further strength.

Model number example (for linear drive)

Pin rack

| PDU050 | - | S | P | A | 080P | - | R |

| | Frame number |

| | |

| Pin rack |

| | |

| Total number of pins |

| specification No symbol: Standard steel type K: Steel type with electroless nickel plating R: Steel type with high rust prevention Y: Flexible type S: Stainless steel type standard specification |

||

| | Drive system S: Linear drive |

| Mounting Method F: Flat type A: Angle type |

||||||

Pin gear

| PDU050 | - | S | G | B | 014T | - | R |

| | Frame number |

| | |

| Pin gear |

| | |

| Number of teeth |

| specification No symbol: Standard steel type K: Steel type with electroless nickel plating R: Steel type with high rust prevention Y: Flexible type S: Stainless steel type standard specification |

||

| | Drive system S: Linear drive |

| Pin gear type B: Single hub type C: Double hub type |

||||||

Model number example (for rotary drive)

Pinwheel

In the case of full circumference

| PDU070 | - | G | P | F | 300P | - | R |

| | Frame number |

| | |

| Pinwheel |

| | |

| Total number of pins |

| specification No symbol: Standard steel type K: Steel type with electroless nickel plating R: Steel type with high rust prevention Y: Flexible type S: Stainless steel type standard specification |

||

| | Drive system G: Outer rotary drive N: Inner rotary drive |

| Mounting Method F: Flat type |

||||||

・Only a portion of the circumference (less than 360°)

| PDU070 | - | G | P | F | 300P | 090P | - | R |

| | Frame number |

| | |

| Pinwheel |

| | |

| Total number of pins |

| Required number of pins |

| specification No symbol: Standard steel type K: Steel type with electroless nickel plating R: Steel type with high rust prevention Y: Flexible type S: Stainless steel type standard specification |

||

| | Drive system G: Outer rotary drive N: Inner rotary drive |

| Mounting Method F: Flat type |

|||||||

Pin gear

| PDU070 | - | G | G | C | 017T | 300P | - | R |

| | Frame number |

| | |

| Pin gear |

| | |

| Number of teeth |

| Total number of pins on pinwheel |

| specification No symbol: Standard steel type K: Steel type with electroless nickel plating R: Steel type with high rust prevention Y: Flexible type S: Stainless steel type standard specification |

||

| | Drive system G: Outer rotary drive N: Inner rotary drive |

| Pin gear type B: Single hub type C: Double hub type |

|||||||

Specification

Corresponding frame numbers by type and specifications

Please be careful when selecting Pin gear drive unit as applicable frame numbers vary depending on the type and specifications.

| Variety | Frame No. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PDU020 | PDU022 | PDU030 | PDU035 | PDU040 | PDU050 | PDU055 | PDU070 | PDU080 | PDU090 | PDU120 | PDU150 | PDU180 | PDU240 | |||

| Steel type |

Standard Specifications | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Electroless Nickel-plated |

○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | - | - | ||

| Highly rust-resistant | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○※ | ○※ | - | - | - | - | ||

| Flexible Type | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

| Stainless steel type | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | ||

*Angle type is not supported for frame numbers above PDU080.

Standard specifications list

There are three types available: steel type, flexible type, and stainless steel type. Please select the type that best suits your environment.

| Frame No. | Pitch mm |

Allowable tangential load kN | ||

|---|---|---|---|---|

| Steel Type | Flexible Type | Stainless steel type | ||

| PDU020 | 20 | 4.7 | - | 0.8 |

| PDU022 | 22 | 7.7 | - | 1.1 |

| PDU030 | 30 | 12.8 | - | 1.9 |

| PDU035 | 35 | 19.5 | - | 2.6 |

| PDU040 | 40 | 27.3 | - | 4.1 |

| PDU050 | 50 | 31.7 | 25.3 | 5.1 |

| PDU055 | 55 | 52.9 | 37.0 | 7.0 |

| PDU070 | 70 | 60.7 | 48.5 | 9.9 |

| PDU080 | 80 | 71.5 | 57.2 | 12.0 |

| PDU090 | 90 | 98.9 | 79.1 | 16.8 |

| PDU120 | 120 | 122.5 | - | - |

| PDU150 | 150 | 240 | - | - |

| PDU180 | 180 | 347 | - | - |

| PDU240 | 240 | 525 | - | - |

| Steel type/flexible type | Stainless steel type | ||

|---|---|---|---|

| Maximum usage speed | Tangential speed: 50m/min | ||

| Usage atmosphere | Indoors (a place not exposed to rain or water) | Corrosive atmosphere | |

| Operating temperature | ‐10℃~150℃ | ‐20℃~400℃ | |

| Material | frame | Rolled steel | Austenitic stainless steel |

| Bush | alloy steel | Precipitation hardening stainless steel | |

| Roller | alloy steel | Austenitic stainless steel | |

| Pin gear | Carbon steel (hardened tooth tip) | Austenitic stainless steel | |

| Frame No. | Backlash mm | Center distance accuracy mm | ||||

|---|---|---|---|---|---|---|

| Steel Type | Flexible Type | Stainless steel type | Steel Type | Flexible Type | Stainless steel type | |

| PDU020 | 0.26 ~ 0.47 | - | 0.26 ~ 0.47 | ±0.25 | - | ±0.25 |

| PDU022 | 0.32 ~ 0.57 | - | 0.32 ~ 0.57 | ±0.3 | - | ±0.3 |

| PDU030 | 0.32 ~ 0.66 | - | 0.32 ~ 0.67 | ±0.4 | - | ±0.4 |

| PDU035 | 0.33 ~ 0.88 | - | 0.33 ~ 0.88 | ±0.5 | - | ±0.5 |

| PDU040 | 0.41 ~ 0.86 | - | 0.41 ~ 0.86 | ±0.6 | - | ±0.6 |

| PDU050 | 0.53 ~ 0.98 | 0.77 ~ 1.22 | 0.53 ~ 1.08 | ±0.7 | ±1.57 | ±0.7 |

| PDU055 | 0.61 ~ 1.06 | 1.01 ~ 1.46 | 0.61 ~ 1.26 | ±0.75 | ±1.72 | ±0.75 |

| PDU070 | 0.86 ~ 1.24 | 1.36 ~ 1.74 | 0.86 ~ 1.61 | ±0.9 | ±2.02 | ±0.9 |

| PDU080 | 0.89 ~ 1.20 | 1.49 ~ 1.80 | 0.89 ~ 1.74 | ±1 | ±2.2 | ±1 |

| PDU090 | 0.97 ~ 1.42 | 1.57 ~ 2.02 | 0.97 ~ 1.92 | ±1.2 | ±2.7 | ±1.2 |

| PDU120 | 1.30 ~ 1.57 | - | - | ±1.6 | - | - |

| PDU150 | 1.63 ~ 1.96 | - | - | ±2 | - | - |

| PDU180 | 1.95 ~ 2.36 | - | - | ±2.4 | - | - |

| PDU240 | 2.60 ~ 3.14 | - | - | ±3.2 | - | - |

Electroless nickel plating specifications

Electroless nickel plating provides a lineup of specifications that achieve excellent wear resistance and corrosion resistance.

This specification ensures effective coating with a uniform surface treatment.

- Examples of use: transport machinery, machine tools, etc.

- Users can select the same size as they would with the standard series since the allowable tangential loads are the same.

-This product is made to order.

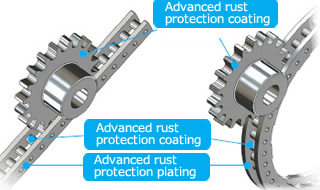

Highly rust-resistant

We offer a lineup of highly rust-resistant specifications that have been enhanced by special surface treatment.

Each part is treated with appropriate rust prevention, providing strong rust prevention in harsh corrosive environments such as outdoors, near water, and in coastal areas.

- Example applications: multi-story parking lots, large transport vehicles, casting lines, water gates, etc.

- Users can select the same size as they would with the standard series since the allowable tangential loads are the same.

- This product is made to order.

Flexible Type

The lineup now includes a flexible type with a wider center distance tolerance and a wider gap between the pin rack/pin wheel and pin gear.

It is effective not only for equipment that requires strict installation precision, but also when the installation position changes during operation due to thermal expansion, etc.

- Examples of use: kiln dryers and civil engineering machinery

- Allowable tangential load is lower than standard series. Refer to the Leafletfor selection.

-This product is made to order.

Special backlash specification (different from the standard allowable tangential load)

-Large backlash specification

Increasing the backlash allows for easy installation.

-Small backlash specification

Backlash can be reduced (2/3 of the standard backlash, compatible frame numbers: PDU020 to PDU120).

Lubrication

Before operation, apply extreme pressure grease to the outer surfaces of all rollers. The inner surfaces of the rollers on the pin wheel or pin rack are pre-lubricated with grease.

Please contact us if you plan to use the product in an environment where lubricating grease cannot be used, such as underwater use, or in a high-temperature environment of 130°C or higher.

Installation Method

Pinwheel, pin rack flat type

A hollow pin is used, so the hole can be used to secure the side to the mating device with a bolt.

When installing, positioning can be done by providing a stopper or guide on the surface with the convex part.

Pin rack angle type

The angled linear rack can be fixed to the mating device using the bolt fastening holes on the leg surface.

More Information

For detailed information on pin wheels, pin racks, and pin gears, please refer to the links below.