Product Info Synchronous Belts and Belt Sprockets

Tsubaki Synchronous Belts are rubber belts with teeth and are also known as toothed belts.

By meshing the teeth on the belt pulley (gear), rotation can be transmitted reliably without slipping, unlike flat belts and V-belts, which transmit power solely through friction.

By embedding glass fiber, aramid fiber, or carbon fiber core wires inside, they have high tensile strength and are used in applications that require accurate positioning and high synchronization.

table of contents

Synchronous Belts related information

-

Selection

-

Materials

-

Operation

Synchronous Belts Features

-

High precision operation is possible.

The meshing transmission allows for accurate operation, and there is almost no belt stretch during operation.

-

Low noise.

It allows for quieter and smoother operation than other transmission elements such as gears.

-

It's a clean transmission.

No lubrication is required.

-

High efficiency.

It can efficiently transmit power from motors and other devices, with almost no energy loss.

-

High speed operation is possible.

Compared to other transmission elements such as gears, it is possible to operate at high speeds.

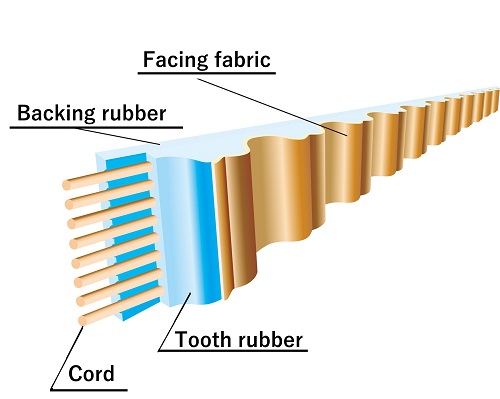

Structure

Backing rubber

耐久性、耐摩耗性を向上させた、クロロプレンゴム(または高強度合成ゴム)により、

心線を保護し長寿命を可能にしました。core wire

伸びが極めて少ない高抗張力グラスファイバー(またはアラミド繊維)を使用し、

高精度伝動を可能にしました。Tooth rubber

背ゴムと一体成形された歯ゴムは、高負荷のかみ合い伝動を可能にしました。Tooth fabric

耐摩耗性および自己潤滑により、スムーズなかみ合いと低騒音を可能にしました。

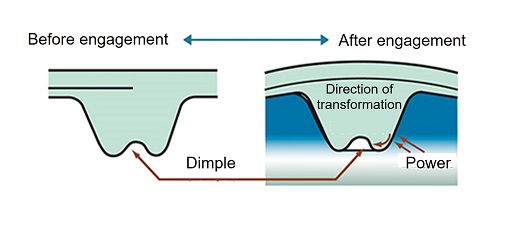

dimple

Low noise due to the effect of special dimples on the tooth tips.

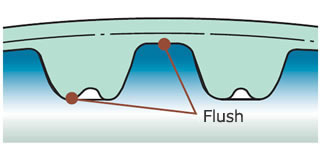

Just Touch Method

The just-touch method of engagement with the pulley, in which both the tooth tip and tooth root come into contact, enables high-precision transmission.

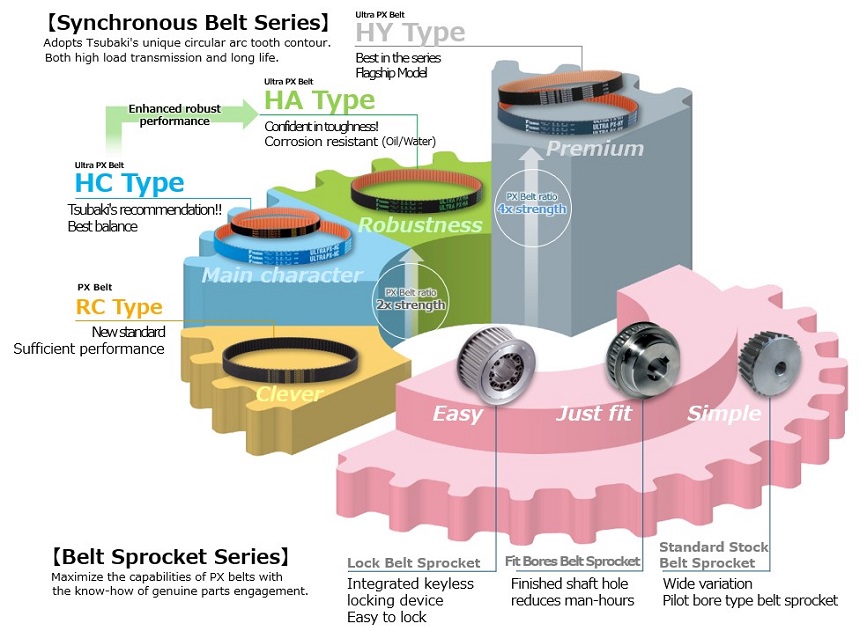

Synchronous Belts and Belt Sprockets lineup

Synchronous Belts and Belt Sprockets product list

Synchronous Belt

Tsubaki's Synchronous Belts use a rational arc tooth profile based on precise meshing theory, and the PX belt and its water-resistant specifications have achieved dramatic improvements in performance, with each component material also being upgraded.

Our lineup includes Ultra PX belts, Open-ended long belts that are ideal for reciprocating motion, and SHINAYAKA 530 specification, which generates minimal rubber powder and is low in dust.

Ultra PX Belt includes HC Type, which has more than twice the power transmission capacity of PX Belt; HY Type, which achieves ultra-high strength and rigidity with a hybrid core wire made of carbon and glass; and the oil-resistant specification, which has the same power transmission capacity as HC Type but can be used in environments where it is exposed to oil and water.

Ultra PX Belt HC type

Model number BG□□□UP□M□□-HC

Power transmission belts with even greater precision and strength

- - Minimal decrease in installation tension allows for stable, high-precision operation

- -High-strength materials are used to support high-load transmission

- - Improved wear resistance of tooth fabric minimizes scattering of wear debris

- - It is easy to know when to replace tooth fabric due to wear.

size

UP3M~UP14M

Ultra PX Belt HA type(Oil proof/Water proof type)

Model number BG□□□UP□M□□-HA

In addition to the same high strength and precision as Ultra PX-HC, this belt also has oil and water resistance.

- - Oil-resistant rubber is used, so the belt's physical properties are hardly affected even in environments where it is exposed to oil or water.

- - It has the same transmission capacity as Ultra PX Belt HC Type, and has extremely little operating elongation.

size

UP5M~UP14M

Ultra PX belt HY type

Model number BG□□□UP□M□□-HY

The strongest and most rigid belt

- - Uses a hybrid core of carbon and glass

- - Transmission capacity 1.3 to 2.0 times that of Ultra PX Belt HC Type

- - High-precision transmission achieved by significantly reducing load elongation

size

UP3M~UP14M

PX belt RC type

Model number BG□□□P□M□□-RC

High-performance belt with our unique arc tooth profile

- ·clean

- ・Long lifespan

- - Reduced operating elongation

- - Visualization of lifespan judgment

size

P5M~P14M

PX Belt

Model number BG□□□P□M□□

With the release of PX Belt RC Type, PX Belt will be sold while supplies last.

Learn more

High-performance belt with our unique PX tooth profile

- - PX tooth profile allows for rational meshing to handle high loads

- -Large belt teeth for high tooth skipping torque

- - Low noise due to special dimples on the tooth tips

- - High precision with just-touch engagement with the pulley

size

P5M~P14M

PX Belt SHINAYAKA 530

Model number BG□□□P□M□□-530

A lightweight belt with minimal scattering of rubber powder

- - Low dust generation allows it to be used in equipment and environments where dirt is undesirable.

- -Because the belt is flexible, installation tension can be low and there is no strain on the mounting shaft.

- ・This specification is available as standard for P2M and P3M.

size

P2M, P3M

PX Belt Waterproof

Model number BG□□□P□M□□-W

Belt ideal for use in wet environments

- -Because they are Synchronous Belts, they are quieter and cleaner than other mechanical elements.

- -PX Standard Stock Belt Sprockets can be used.

- - It has a transmission capacity approximately 1.2 times that of PX Belt, allowing for a compact design.

size

P5M, P8M

Open-ended belt

Model number BG-P□M-H+□□□.□M, BG-P□MT□□□M

With the release of Open-ended belt (PX Belt RC Type), Open-ended belt (PX Belt) will be available while supplies last.

For details, Here

Open-end belt that can be used over Gliding arrangement

- ・Ideal for reciprocating drives and Gliding arrangement transmission

- ・A wide range of models

- PX Belt RC Type, Ultra PX Belt HC Type, HA Type, and HY Type can be selected

- ・Three length patterns can be specified

- Specify number of teeth / Specify metric / Specify standard length

- - Features similar to each series

- Clean / Low operating elongation / Thin / Easy to determine end of life / Wide range of purchasing options

size

P2M~P8M

UP3M~UP8M