Lock Belt Sprockets S Type

- The most standard type of Lock Belt Sprockets

- *Strong fastening allows use with Ultra PX Belt

- *Flat mounting is lightweight and space-saving

- *The pulley body is made of extra-super duralumin "S-type aluminum" and electroless nickel-plated type are also available.

- * Effective in further reducing weight and inertia

Features

- * Strong, non-backlash connection between shaft and pulley.

- *No need for keys or axial retainers, positioning and phase alignment can be easily performed.

- *Easy to install and remove with only a few bolts.

- * Easy ordering by model number. No need to create a shaft bore machining drawing.

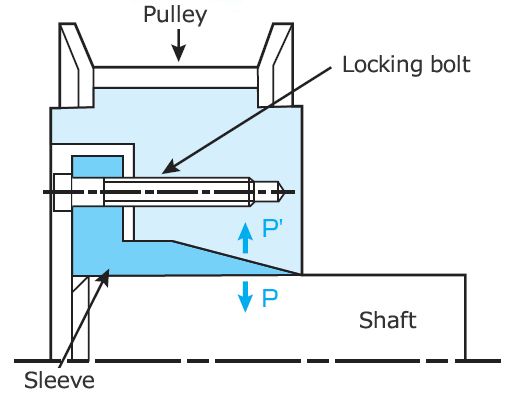

1. Fastening Principle

The inner diameter of Belt Sprockets and the outer diameter of the sleeve are tapered, and by tightening the tightening bolts,

Belt Sprockets move by sliding on a tapered surface.

At this time, a wedge action generates forces P and P' that press against the shaft and the inner surface of the tapered surface.

This P and P' force generates a frictional force that tightly fastens Belt Sprockets and shaft together.

*Click to enlarge the illustration

2. Lock Belt Sprockets S type, plated

The S-type Lock Belt Sprockets is plated with electroless nickel plating.

- - The pulley body and sleeve are electroless nickel plated, and the bolts are specially coated.

- In addition to strong, zero-backlash fastening, it also has improved corrosion resistance and dry fastening that does not require lubrication.

Catalogs and Instruction Manuals

Product model number list

*Click on the model number to display detailed information.