Power Cylinder Worm Series

- The worm series is an electric cylinder that is ideal for replacing hydraulic cylinders.

- The LPWB Worm Series utilizes a high-precision worm gear that utilizes the technology Tsubaki has cultivated over many years, and a highly efficient Ball screw, achieving large thrust.

- Allowable thrust: 49 to 490 kN

- Nominal speed: 5-72mm/s

Features

-

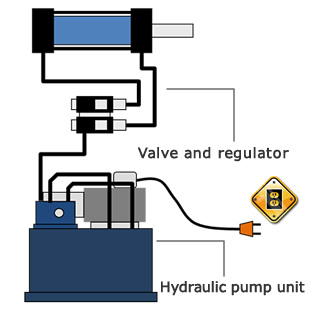

·clean

Since there are no hydraulic pumps or piping, there is no need to worry about oil leaks from joints.

-

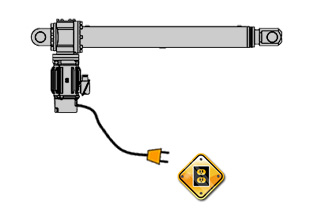

Easy to install

No hydraulic pump or piping is required. Just connect a three-phase power supply and it will operate.

-

・Accurate control possible

Speed changes and accurate positioning are possible using inverters, etc.

-

・Low cost

The number of parts has been significantly reduced, resulting in cost savings.

-

・High load capacity

By using a special alloy, it can handle heavy loads just like a jack (maximum load of 50t in the large thrust zone).

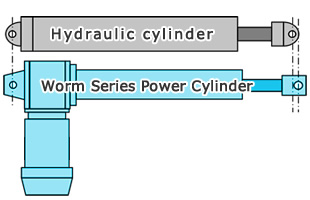

Compact shape that is as close to a hydraulic cylinder as possible

- - A high-precision worm gear made by Tsubaki is used in the reduction section, and the support structure for Ball screw and gear section is integrated.

- - Unlike conventional electric cylinders, the bracket section is not required, so the overall length can be significantly reduced.

- - The main body is mounted using clevises on both ends, which is the most popular method for mounting hydraulic cylinders.

No pump or piping required, easy to install

Hydraulic cylinder

Power Cylinder Worm Series

Power Cylinder can be operated simply by connecting the power supply

Simple thrust calculation for hydraulic cylinders

-

You can try out the thrust calculation online to convert hydraulic cylinder output into approximate Power Cylinder thrust.

option

・L: Stroke adjustment external LS (2 pieces included)

・R: Rotary encoder

・Y: Counter LS *1

・C: With clevis fittings

-

・K2, K4: Stroke adjustment internal LS

-

・J: With bellows *2

-

・P: Potentiometer

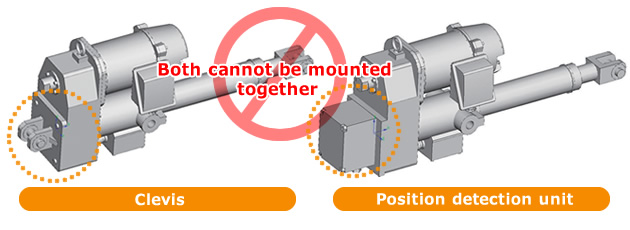

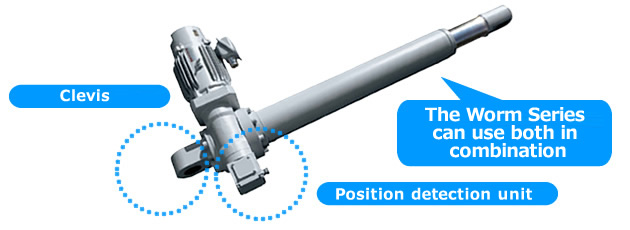

- It is now possible to combine clevis fittings and position detection units, which was not possible with conventional Power Cylinder.

Power Cylinder Worm Series

- *1 If counter LS is installed, it cannot be used in combination with K2, K4, P, or R.

- *2 Stroke remains the same.

Model number display example

| LPW | B | 5000 | DR | 10 | □□C |

| | Series Name |

| Screw Type |

| Allowable thrust |

| Body shape |

| stroke |

| option |

| Power Cylinder Worm Series |

B: Ball screw | Right angle shape | 2:200mm 5:500mm 10:1000mm |

Product model number list

| Model number | Allowable thrust *1 | Motor Capacity kW |

Reference dimensions | Rated thrust *2 (Thrust varies depending on speed ratio) |

speed mm/s |

Nominal stroke mm |

Motor Specifications | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kN | {kgf} | kN | {kgf} | ||||||||||

| LPWB5000 | 49 | 5000 | 0.4 | 0.98~28.4 | 100~2900 | 24~5 | 200~1000 | With non-excitation operated brake three phase induction motor IP55 equivalent |

|||||

| 0.75 | 3.92~49.0 | 400~5000 | 36~5 | ||||||||||

| 1.5 | 18.6~49.0 | 1900~5000 | 36~5 | ||||||||||

| LPWB10000 | 98 | 10000 | 0.75 | 3.92~38.2 | 400~3900 | 20~6.6 | 500~1500 | ||||||

| 1.5 | 1.96~96.0 | 200~9800 | 48~6.6 | ||||||||||

| 2.2 | 11.7~98.0 | 1200~10000 | 48~6.6 | ||||||||||

| 3.7 | 33.3~98.0 | 3400~10000 | 48~6.6 | ||||||||||

| LPWB20000 | 196 | 20000 | 3.7 | 3.92~196 | 400~20000 | 72~10 | 500~2000 | ||||||

| 5.5 | 25.4~196 | 2600~20000 | 72~10 | ||||||||||

| 7.5 | 49.0~196 | 5000~20000 | 72~10 | ||||||||||

| LPWB30000 | 294 | 30000 | 5.5 | 5.88~294 | 600~30000 | 72~10 | 500~2000 | ||||||

| 7.5 | 30.3~294 | 3100~30000 | 72~10 | ||||||||||

| 11 | 71.5~294 | 7300~30000 | 72~10 | ||||||||||

| LPWB50000 | 490 | 50000 | Please contact us | 500~2000 | Please contact us | ||||||||

- * Allowable thrust is the maximum load that the cylinder itself can tolerate.

- * Rated thrust is the thrust converted from the motor's rated torque.

- *If inverter driven, the rated thrust must be confirmed.

- *The above specification table shows the generating capacity at a motor time rating of S2: 30 min and Percentage duty cycle of 25% ED.

- If the frequency is low, it is possible to reduce the motor size.

- *In addition to the specifications listed above, we can also accommodate special combinations.

- *The drawing is for reference only. Dimensions may change depending on the detailed specifications.

- *Please contact us for details.

Special support

・Special support is available to suit your usage conditions.