Zip Master

- Zip Chain adopted cantilever type Electric Lifter

- - High-speed driving

It is capable of high speed lifting and lowering at a maximum of 1000mm/s (60m/min). - - High frequency operation

High frequency operation is possible even with multiple stops. - ・Long lifespan

It has a long life of 1 million lifting movements and is easy to maintain. - ・High lift

Standard Long travel length of over 2m are also possible.

What is Zip Chain?

- High-speed, high-frequency operation

- Multi-point stop function

- By far the most space-saving

Zip Chain is a chain developed exclusively by our company, in which two chains interlock like a zipper to form one strong pillar that can be pushed and pulled.

The Tsubaki Zip Chain Actuator is a commercialized linear actuator that uses this chain.

Compared to conventional pneumatic and hydraulic cylinders, they have many features, including environmental friendliness, such as space saving, high speed and high frequency operation, multi-point stopping function, high stopping accuracy, and freedom of installation direction, and are used in a wide range of applications from small actuators to large lifters.

Video content

Tsubaki Zip Master ZME Series

Features

High-speed, high-frequency operation that surpasses other drive systems

The use of Zip Chain that allows for continuous operation enables high-speed, high-frequency operation that surpasses other methods.

- ・High speed: max. 1000mm/s

- ・High frequency: 300 round trips per hour possible

- ・Long life: Over 1 million lifts and down strokes

Self-standing type with excellent rigidity even with Long travel length

It uses a compact yet highly rigid support column. It has a built-in linear guide, so it can withstand overhang loads even with Long travel length.

- ・High lift: Supports over 2000mm

- -High rigidity: Uses the same linear guide as Lift Master

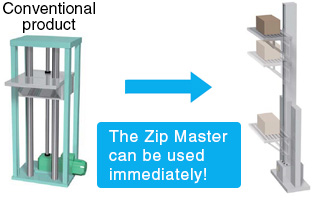

Easy installation of the "plug and play type reduces assembly time

"plug and play type that integrates Zip Chain, linear guide, and motor

Unlike conventional elevators, which require a lot of design and assembly time, Zip Master can be used simply by placing it.

* Can also be used as a vertical conveyor.

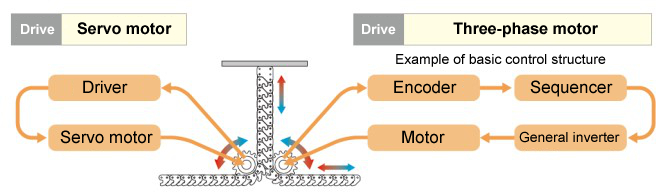

Multi-point stopping and multi-stage positioning

Zip Master 's simple control configuration makes it easy to achieve multi-point stopping and multi-stage positioning.

Structure and comparison with other methods

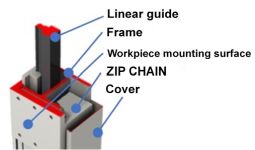

■ Unique internal structure

Comparison with drop lifter

Conventional vertical transport lifters require on-site assembly, and scaffolding must be set up on the ceiling to install and inspect the drive unit.

Zip Master 's one-piece structure makes it easy to assemble and install, and the drive unit is located on the floor, making inspection and maintenance safe and easy.

For a comparison of Zip Chain mechanism and the screw mechanism, please see here.

Specification

- ・Lifting load: 1.96kN to 9.80kN

- ・Stroke: 1,500mm/2,000mm

- ・Speed: 330~1,000mm/s (19.8~60m/min)

- ・Drive unit: with three-phase motor/servo motor

Catalogs and Instruction Manuals

Model number display

| ZME | L | 0500 | H | 20 | G | E |

| | | Zip Master |

| | Linear guide system |

| Lifting load 0200: 1.96kN {200kgf} 0500: 4.90kN{500kgf} 1000: 9.80kN {1000kgf} |

| speed M, H, U The speed is as follows Product model number list Please refer to. |

| stroke 15: 1500mm 20: 2000mm |

| Drive unit G: With three-phase motor K: With servo motor |

| option See below for details |

■ Tsubaki model No. navigation

What type of screws are used?

Lifting load

This is the load that can be raised or lowered at the specified center of gravity.

speed

This symbol indicates the lifting speed.

Please refer to the detailed information for the speed values of each model.

Stroke

The distance that can be raised or lowered.

Drive unit

G: Comes with a three-phase motor.

K: It comes with a servo motor.

Option symbol

L1: Add one position detection sensor.

V: This specifies the power supply voltage will be doubled.

E: A rotary encoder is attached to the rear of the motor.

Product model number list

*Click on the model number to display detailed information.

| Lifting load kN{kgf} |

stroke mm |

Drive unit | Speed M (19.8m/min) |

Speed H (48m/min) |

Speed U (60m/min) |

|---|---|---|---|---|---|

| 1.96 {200} | 1500 | G (with three-phase motor) | --- | --- | ZMEL0200U15G |

| 2000 | --- | --- | ZMEL0200U20G | ||

| 4.90 {500} | 1500 | --- | ZMEL0500H15G | --- | |

| 2000 | --- | ZMEL0500H20G | --- | ||

| 9.80 {1000} | 1500 | ZMEL1000M15G | --- | --- | |

| 2000 | ZMEL1000M20G | --- | --- | ||

| 1.96 {200} | 1500 | K (with servo motor) | --- | --- | ZMEL0200U15K |

| 2000 | --- | --- | ZMEL0200U20K | ||

| 4.90 {500} | 1500 | --- | ZMEL0500H15K | --- | |

| 2000 | --- | ZMEL0500H20K | --- | ||

| 9.80 {1000} | 1500 | ZMEL1000M15K | --- | --- | |

| 2000 | ZMEL1000M20K | --- | --- |

option

Add a position detection sensor [Option symbol: L1]

- The standard product is equipped with four position detection sensors, but one additional sensor can be added.

・If you would like to add more sensors, please contact us.

Compatible sizes: All standard model numbers

Motor voltage 400V class [option code: V]

・Change the drive motor voltage to 400V class.

Compatible sizes: ZMEL0200U□□G, ZMEL0200U□□K, ZMEL0500H□□K, ZMEL1000M□□K

*If you have selected ZMEL0500H□□G or ZMEL1000M□□G and require a motor voltage of 400V class, please contact us.

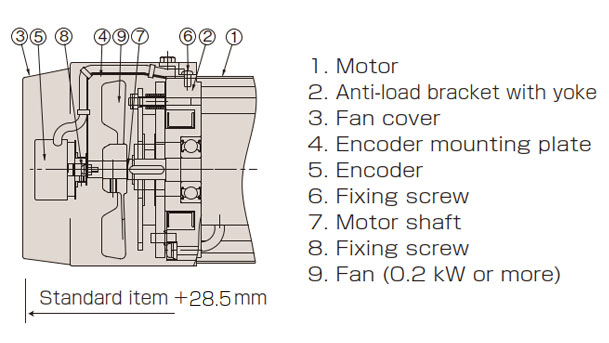

With rotary encoder [Option code: E]

- A rotary encoder can be installed on the shaft end of the non-load side of a three-phase motor, enabling the motor rotation signal to be output.

Compatible size: ZMEL0200U□□G

*If you have selected ZMEL0500H□□G or ZMEL1000M□□G and would like a rotary encoder, please contact us.

Features

・Controllability

An open collector output signal can be extracted from the reducer, allowing for a variety of operations.

·compact

There is no need to connect the motor shaft and rotary encoder with a coupling.

・Cost reduction

Compared to conventional separate installations, there is no need for couplings, base plates, or leveling work.

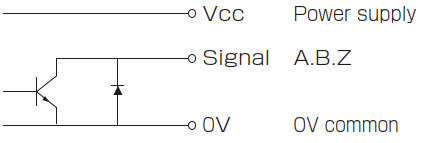

Rotary encoder specifications

| Power supply voltage | DC4.5~30V |

|---|---|

| Number of pulses | 100 |

| Output format | Open collector output (NPN type) 6 AB90° phase difference signal +Z origin signal |

| Output Circuit | |

| Current consumption | 30mA or less |

| Output Voltage | 0.5V or less (At maximum sink current) |

| Maximum sink current | 40mA MAX |

| Signal rising Fall time |

1μs or less |

| Maximum Response Frequency | 240kHz |

| Output circuit withstand voltage | 50V MAX |

| Cable length | 0.5m with connector (Hirose Electric Co., Ltd. DF3-6S-2C) |

| vibration | 4.9m/s 2 {0.5G} or less (20~50Hz) |

Selection

Our staff will select the lifter that meets your requirements and requirements.

Please click on the "sizing" tab at the top of this page.

Points to note when considering Zip Master

- - Because Zip Master has a fast lifting speed, inverter control is required and sufficient acceleration and deceleration time must be provided.

Sudden acceleration or stopping may result in a decrease in stopping accuracy or vibration of the workpiece.

If Zip Master vibrates when starting and stopping due to the installation surface, arm rigidity, or load conditions, please use it with a longer acceleration/deceleration time.

Also, if you want to reduce the amount of vibration, consider fixing the top of Zip Master.

- ・ Zip Master 's nominal speed is the maximum speed.

When calculating the lift time, please include the acceleration and deceleration time in the calculation.

- ・Servo motor drive is recommended when further reductions in lifting time, high frequency operation, multi-point positioning, linked operation, etc. are required.

Please contact us as we can accommodate your desired servo motor manufacturer.

- - A large regenerative current is generated when descending, so please provide an inverter regenerative resistor with sufficient capacity based on your usage conditions.

Please consult the inverter manufacturer regarding the capacity of the regenerative resistor.

- ・We recommend using an inverter with a capacity one frame larger than the motor.

- - Create a sequence that activates the brake when the inverter trips.

- ・ Zip Master uses a motor with a non-excitation brake.

If you are providing your own motor as a servo motor, please use the brake-equipped keyway shaft specification.

In addition, please prepare a fall prevention mechanism in case of an accidental fall.

We can also manufacture special-order drop prevention pins.