Power-Lock KE Series

- The lineup includes shafts with small diameters and can be used with shafts with a wide range of tolerances (except for KE-KP).

- ・Compatible with a wide range of shaft tolerances. Standard products are compatible with plus tolerance shafts of servo motors, etc.

- - The small inner/outer diameter ratio allows for compatibility with small-diameter hubs, enabling compact designs.

- * Centering function included. No need for troublesome boss step processing.

- * The boss does not move during assembly.

Standard Specifications

- - With a lineup starting from small diameter sizes, it is ideal for fastening small stepping motors and servo motor output shafts.

- - Simple structure with few parts, excellent cost performance.

- Applicable shaft diameter: Φ5 to Φ100

- トルク範囲:7.5~9900N・m

- Applicable tolerance: Axis: h6, h7, js6, js6, k6, m6, (h9, h10) hub bore: H8

- Applicable surface roughness: Ra1.6

*When the shaft tolerance is h9 or h10, the transmission torque will be 90% of the catalog value.

Stainless steel specifications

- - The main body is made of austenitic stainless steel, which provides high corrosion resistance.

- - The tightening bolts have a special lubricating coating, so there is no need to apply oil during assembly.

- - It has a higher transmission torque than other companies' products, but is designed to reduce the surface pressure generated, so it can also be used with small hub diameter.

In addition, the number of tightening bolts is small, which reduces assembly work. - · As with the KE series, this standard product is compatible with positive tolerance shafts of servo motors, etc.

- Applicable shaft diameter: Φ5 to Φ50

- トルク範囲:5.0~836N・m

- Applicable tolerance: Axis: h6, h7, js6, js6, k6, m6, (h9, h10) hub bore: H8

- Applicable surface roughness: Ra1.6

*When the shaft tolerance is h9 or h10, the transmission torque will be 90% of the catalog value.

Electroless nickel plating specifications

- · Both dimensions and transmission torque are the same as the KE standard series. There is no torque reduction.

- - The main body is electroless nickel plated, which does not peel off.

- The tightening bolts have a special surface treatment that provides lubrication, eliminating the need to apply oil during assembly. They are chrome-free and environmentally friendly.

- *Please note that unlike other specifications, the applicable shaft tolerance is h8 and hub bore tolerance is H8.

- Applicable shaft diameter: Φ5 to Φ100

- トルク範囲:7.5~9900N・m

- Applicable tolerance: Shaft: h8 Hub bore: H8

- Applicable surface roughness: Ra1.6

Low Contact Pressure series

- - By using a special bolt, the generated surface pressure is reduced. (Bolt color: blue)

- ・It can be used for small hub diameter that were previously insufficient in strength to withstand the surface pressure generated due to insufficient thickness.

- ・It can also be considered when the shaft strength is insufficient.

- - As with the standard specification, it can accommodate a wide range of shaft tolerances.

- *Transmission torque is lower than the standard specification, so please check the product details screen from the product list.

- Applicable shaft diameter: Φ5 to Φ100

- トルク範囲:6.3~8290N・m

- Applicable tolerance: Axis: h6, h7, js6, js6, k6, m6, (h9, h10) hub bore: H8

- Applicable surface roughness: Ra1.6

*When the shaft tolerance is h9 or h10, the transmission torque will be 90% of the catalog value.

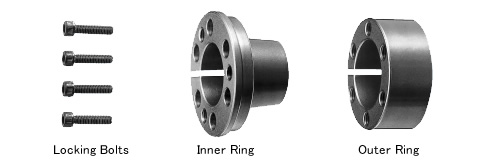

Structure

Single Taper

The Power-Lock KE series has a simple structure consisting of three parts: an inner ring, an outer ring, and a fastening bolt.

It can be firmly fastened by simply tightening the fastening bolts.

Video content

Features and Structure

Handling Instructions

Catalogs and Instruction Manuals

Model number display example

| PL | 005 | X | 016 | KE | - | SS |

| | Shaft diameter |

| Outer diameter |

| Series Name |

| specification |

|||

| None: Standard specification SS: Stainless steel KP: Electroless nickel plating LP: Low Contact Pressure series |

||||||

Product List

*Click to display detailed information.