Power-Lock Simple Selection Tool

Target varieties

Power-Lock:

AS series, AS-KP series, AS-SS series

AD-N series, AD-N-KP series, AE series

RE-SS series, KE series, KE-KP series

KE-SS series, KE-LP series, TF series

TF-KP series, ML series, EF series, EL series

Use of Content

- Before using TSUBAKI Power Transmission Products Information Site Power-Lock Simple Selection Tool (hereinafter referred to as "this tool"), please be sure to read the following usage precautions and disclaimers, and use this tool only if you agree to all of the contents.

- If you do not agree, please refrain from using this tool.

Precautions for use and disclaimers

sizing Power-Lock

We will select the appropriate Power-Lock based on your specified conditions.

When selecting "Select from shaft diameter," select the model number that matches the specified shaft diameter and determine whether it satisfies the specified torque.

When selecting from torque, select the model number with the smallest shaft diameter that satisfies the specified torque.

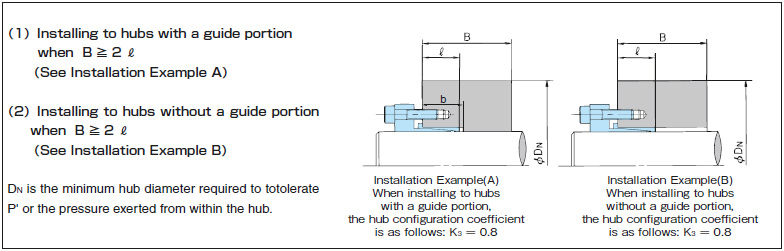

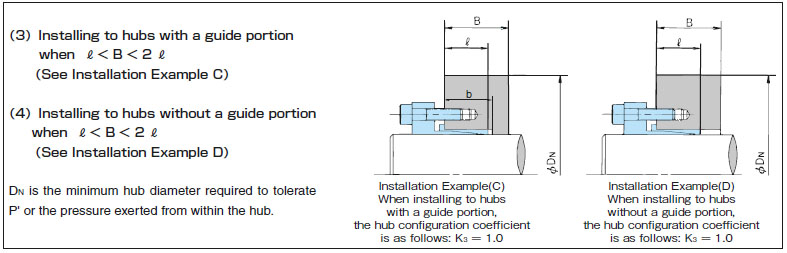

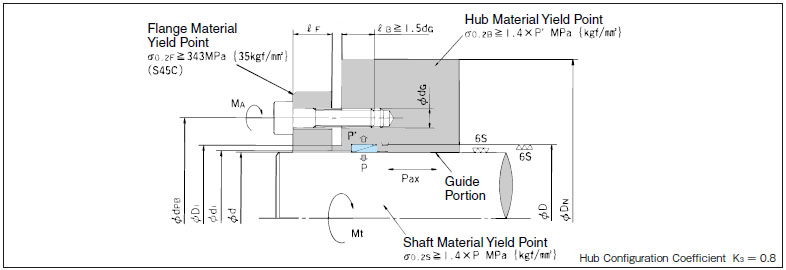

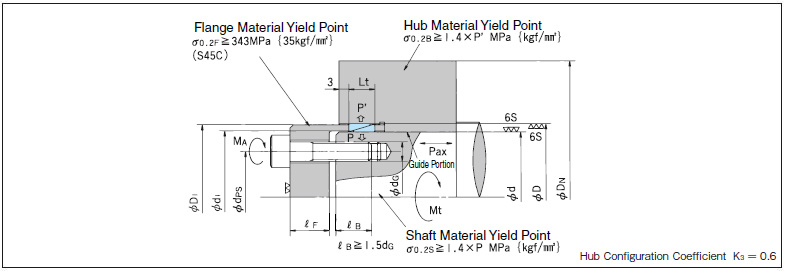

In either case, the shaft and boss surface pressure tolerance is determined, the minimum outer hub diameter required, and the maximum hollow shaft inner diameter are determined.

The radial load tolerance will be displayed, so please check it.

Enter the selection criteria

・Please use “.” for the decimal point and not “,” as the calculation error will occur.

Enter the shaft diameter

Shaft diameter: mm

Enter the transmissible torque

Transmissible Torque: N・m

Service factor:

Transmission capacity:kW

Rotational speed:r/min

If a thrust load is applied, input

Thrust load: N

If a radial load is applied, input

Radial load: N

Enter the yield point of the shaft and boss material

Shaft material yield point: MPa

Boss material yield point: MPa

Transmissible torque calculation results

N・m

*No safety factor is taken into account in the minimum required boss diameter.

For detailed selection procedures and calculation formulas, please see here.

Selection results

*For the EL series, this is the calculation result when pressure is applied using the bolt size, number of bolts, and tightening torque shown in the recommended fastening example above.

Please contact us for selection under pressure conditions other than those shown here.

| Series | Model number Click for Product Info |

Shaft diameter [mm] |

Outer diameter [mm] |

Tolerance torque [N・m] |

torque judgement |

Unit price/ delivery | series coefficient K2 |

shaft side Surface pressure [MPa] |

shaft side Surface pressure judgement |

boss Outer diameter side Surface pressure [MPa] |

boss Outer diameter side Surface pressure judgement |

need Boss material yield point |

boss strength judgement |

hollow shaft Maximum inner diameter [mm] |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SL | Candidate 1 | ||||||||||||||

| Candidate 2 | |||||||||||||||

| Candidate 3 | |||||||||||||||