Product Info Plastic modular chain Accessories

We have a wide lineup of conveyor peripheral parts such as dedicated sprockets, idlers, Plastic rail, set collars, chain guide parts, frame support parts, product guide parts, and bearing units.

- For Plastic modular chain

- Chain guide parts

- Frame Support Parts

- Product Guide Parts

- Set Color

Bearing Unit

Please click on the images below to see how to use each accessory.

- Plastic rail

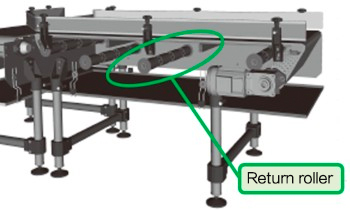

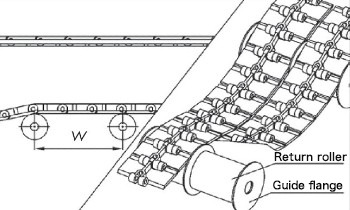

- Return roller

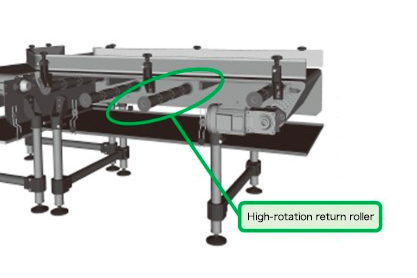

- High rotation return roller

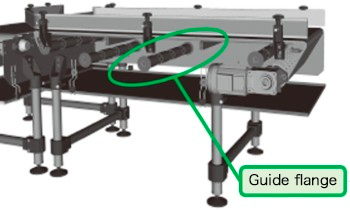

- Guide flange

- Sliding shoe

- Spacer

- Washer

- Dedicated rail

- Module Transfer

Roller plate

High rotation return roller

-

・Application

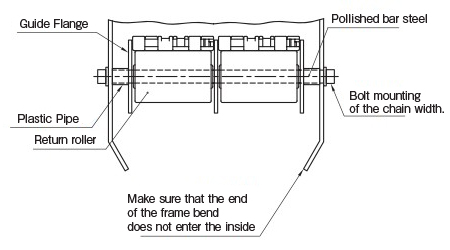

Use as a chain receiver on return-way of the conveyor.

The rotation of the rollers reduces sliding resistance and reduces scratches on the top surface of the chain.

The inner circumference is made of engineering plastic material which has low resistance to the shaft, and the outer circumference is made of soft material which has high resistance to the chain, resulting in excellent rotational performance.

It is also effective when you want to prevent scratches on the top surface of the chain and to reduce noise on return-way of the conveyor.

-

・Usage image

Sliding shoe

-

・Application

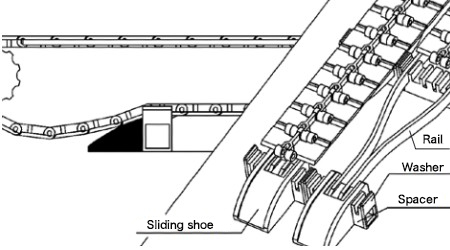

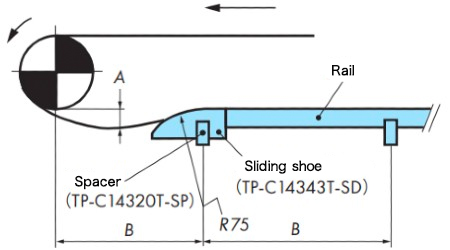

■Fixed type:

Used as a chain support on return-way of the conveyor, in combination with spacers, washers, and dedicated rails.

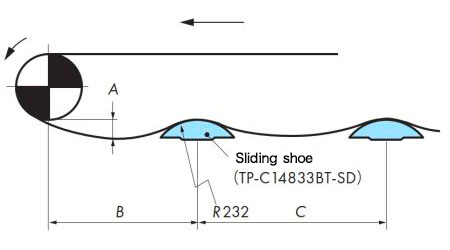

Please use it.■Swing type:

For low-speed (50m/min or less) accumulation chain and Plastic Roller table conveyors

By supporting the top of the chain on return-way, sliding resistance is reduced and scratches on the top of the chain are reduced.*Accumulation chains and Plastic Roller tables are chains with rollers,

If return rollers are used, the rollers may become tangled. -

・Usage image

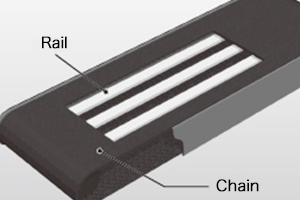

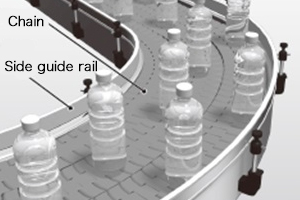

Plastic rail

-

・Application

Made from ultra-high molecular weight polyethylene (UHMWPE), it offers excellent sliding properties and abrasion resistance.

We have a wide variety of products available, and they are commonly used for rails.

-

・Usage image

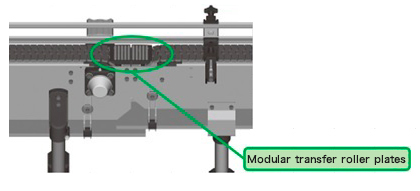

Module Transfer Roller Plate

-

・Application

Installing rollers at the transfer points between conveyors prevents items from remaining at the transfer points. The rolling of the rollers also reduces resistance at the transfer points, reducing the risk of items tipping over.

-

・Usage image