Selection Guide Large size conveyor chain

- Want to reduce environmental impact

- Want to improve transport capacity

- I want to improve my problems

- I want to use it in a corrosive atmosphere

- Choose by purpose

- Want to use it for general purposes and economically

- I want to see applied equipment and accessories

Large size conveyor chain DT Series

Model number RF□□□□□R・F・S・M・N-DT~

The most economical general-purpose conveyor chain (basic model).

- -We offer a lineup of metric pitch and inch pitch types.

- Various attachments are available.

- - The pins and bushings are heat treated, but the plates are not.

- ・Operating Ambient Temperature: -20℃ to 200℃

Size

RF03トン~RF120トン

RF430~RF212

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller

Large size conveyor chain DTA Series

Model number RF□□□□□R・F-DTA~

Improved wear resistance for general-purpose Large size conveyor chain DT Series (Advanced model).

- - Compared to DT Series, this specification improves wear resistance between the bushing and roller by three times.

- ・Only R rollers and F rollers are supported.

- ・Operating Ambient Temperature: -20℃ to 200℃

Size

RF03 tons to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller

Large size conveyor chain AT Series

Model number RF□□□□□R・F・S・M・N-AT~

Compared to general-purpose conveyor chains (DT Series), it has approximately twice Maximum allowable load between the bushing and roller.

Improved wear resistance and roller allowable load (basic model).

- -We offer a lineup of metric pitch and inch pitch types.

- Various attachments are available.

- Ambient temperature: -20°C* to 400°C

*Please contact us regarding use below -20°C.

Size

RF03トン~RF440トン

RF430~RF212

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller,

N roller

Large size conveyor chain ATA Series

Model number RF□□□□□R・F-ATA~

This is a higher-end specification than AT Series. It has improved wear resistance and Maximum allowable load. (Advanced model)

- - Compared to AT Series, the wear resistance between the bush and roller is doubled, and the wear resistance between the pin and bush is 1.5 times greater.

Maximum allowable load has been increased by 1.2 times. - - Compatible with RF08 to RF36 sizes, R rollers and F rollers only.

- Ambient temperature: -20°C* to 200°C

*Please contact us regarding use below -20°C.

Size

RF08 to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller

Large size conveyor chain GS Series

Model number RF□□□□□R・F・S・M-GS~

Stainless steel chain (basic model) with improved corrosion resistance compared to DT Series

- - Improved corrosion resistance compared to general-purpose Large size conveyor chain DT Series.

- - The material used is stainless steel (stainless steel 400 series).

- ・Operating Ambient Temperature: -20℃* to 400℃

- *Please contact us for use below -20°C.

Size

RF03トン~RF26トン

RF430~RF212

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller,

N roller

Large size conveyor chain GSA Series

Model number RF□□□□□R・F・S・M-GSA~

High-end version of GS Series. Features improved wear resistance and maximum allowable load (Advanced model).

- - Compared to GS Series, the wear resistance between the bush and roller is twice as high, and the wear resistance between the pin and bush is 1.5 times higher.

Maximum allowable load and the allowable load of the R roller and F roller have been improved by 1.3 times. - Ambient temperature: -20°C* to 200°C

- *Please contact us for use below -20°C.

Size

RF03 to RF26 tons.

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller

Large size conveyor chain SS Series

Model number RF□□□□□R・F・S・M-SS~

This is a higher specification than GS Series. Stainless steel chain with excellent corrosion resistance, chemical resistance, heat resistance, and cold resistance.

(Basic model)

- - The material used is stainless steel (stainless steel 300 series).

- ・Operating Ambient Temperature: -20℃* to 400℃

- *Please contact us for use below -20°C.

Size

RF03トン~RF26トン

RF430~RF212

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller

Large size conveyor chain SSA Series

Model number RF□□□□□R・F・S・M-SSA~

Improved wear resistance between the bushing and roller of SS Series (Advanced model).

- -Compared to SS Series, this specification improves wear resistance between the bushing and roller by 1.5 times.

- - The allowable roller load for the R roller and F roller has also been improved by 1.3 times.

- ・Operating Ambient Temperature: -20℃ to 200℃

Size

RF03 to RF26 tons.

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3, GA2, GA4, etc.

Roller type

R roller, F roller,

S roller, M roller

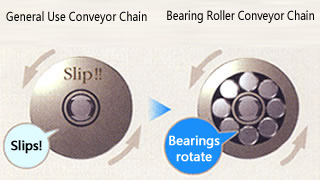

Load capacity Large size conveyor chain (Bearing Roller Conveyor Chain)

Bearing Roller Conveyor Chain has a unique structure with cylindrical bearing inside the rollers, which reduces chain running resistance, significantly improves roller allowable load, and extends the wear life between the bushing and roller.

This achieves improvements that were difficult to achieve with conventional conveyor chains, such as "higher efficiency," "lower costs," "suppression of stick-slip phenomenon *," and "extended roller and rail life."

In addition to the standard specifications, we also offer dust-resistant specifications, Lube-free specifications, Water Resistant Lube Free Series, etc., so you can choose the model that best suits your needs.

*The chain repeatedly moves and stops even though the drive unit is operating continuously.

We also offer the convenient Screw Lock Link, which allows connection and disconnection with just a torque wrench.Learn more.

1. Bearing Roller Structure

2. Function of bearing rollers

- - Reduced chain running resistance (1/3 of general-purpose products)

- - Significant increase in roller allowable load

3. Effect of bearing rollers

- -Reduction of chain tension and required power

- ・Prevents jerking during conveyor length and slow operation

- - Reduced roller rotation problems and rail wear

- - Improved wear life (between bushing and roller)

- ・Reduction of CO2 emissions and electricity bills

Product lineup

Bearing Roller Conveyor Chain Standard Series

Model number RF□□□□□BR・BF-DT・AT~

Our unique structure with cylindrical bearing inside the rollers allows for the smooth running of general-purpose conveyor chains (DT Series).

It has approximately 5 times longer wear life.

- - The motor power required can be reduced by approximately 1/3 and the chain size can be reduced by 2 sizes.

- -Contributes to reducing the cost of the entire facility.

- - The dimensions are the same as the R roller and F roller of RF conveyor chain.

- Ambient temperature: BR, BF: -20℃ to 80℃

Size

RF03 tons to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

BR roller, BF roller

Bearing roller conveyor chain Anti-Dust Series

Model number RF□□□□□DBR・DBF-DT・AT~

By using a labyrinth structure and seals, this conveyor chain is less susceptible to dust intrusion than standard Bearing Roller Conveyor Chain.

- - The labyrinth structure and seal make it difficult for dust to enter, and in dusty environments the wear life is three times longer than the standard specification.

- -There are two types of rollers: DBR and DBF.

- ・使用雰囲気温度:-10℃~80℃

Size

RF 10 tons to RF 36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

DBR roller, DBF roller

Bearing Roller Conveyor Chain Standard Lube Free Series

Model number RF□□□□□EBR・EBF-DT・AT~

Special cylindrical bearing with self-lubricating properties are used between the bushing and roller, so the roller part

It can be used Lube-free, and no additional oil is required.

- -There are two types of rollers: EBR and EBF.

- ・使用雰囲気温度:-20℃~50℃

- *Please note that Maximum allowable load differs from that of the standard series. The allowable roller load is the same.

Size

RF03 tons to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

EBR roller, EBF roller

Bearing Roller Conveyor Chain Completely Lube Free Series

Model number RF□□□□□AEBR・AEBF-DT・AT~

No additional oil is required between the pin and bushing or between the bushing and roller.

- - Steel rollers and special cylindrical bearing are installed alternately inside the roller.

Furthermore, by crimping and sealing a solid lubricant onto the inner surface of the bushing, no additional lubrication is required between the pin and bushing or between the bushing and roller. - -There are two types of rollers: AEBR and AEBF.

- Please note that Maximum allowable load differs from that of the standard series. The allowable roller load is the same.

- ・使用雰囲気温度:-20℃~50℃

Size

RF05 tons to RF26 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

AEBR roller, AEBF roller

Bearing Roller Conveyor Chain Water Resistant Lube Free Series

Model number RF□□□□□WEBR・WEBF-GS~

By alternately placing stainless steel rollers and special cylindrical rollers inside the roller, it can be used in an environment where water splashes.

It can be used without additional lubricating.

- -There are two types of rollers: WEBR and WEBF.

- ・使用温度範囲:0℃~50℃

Size

RF03 tons to RF36 tons

For inch sizes,

please contact us

Attachment Type

A1, A2, A3, K1, K2, K3

Roller type

WEBR Roller, WEBF Roller

Industry-specific products

We have compiled a lineup of industry-specific products by compiling the track record of conveyors specific to each industry.

Each specification can be applied to industries other than the relevant industry, so please contact us for more information.

Cement Industry

Steel industry

(Transportation of ultra-heavy objects)

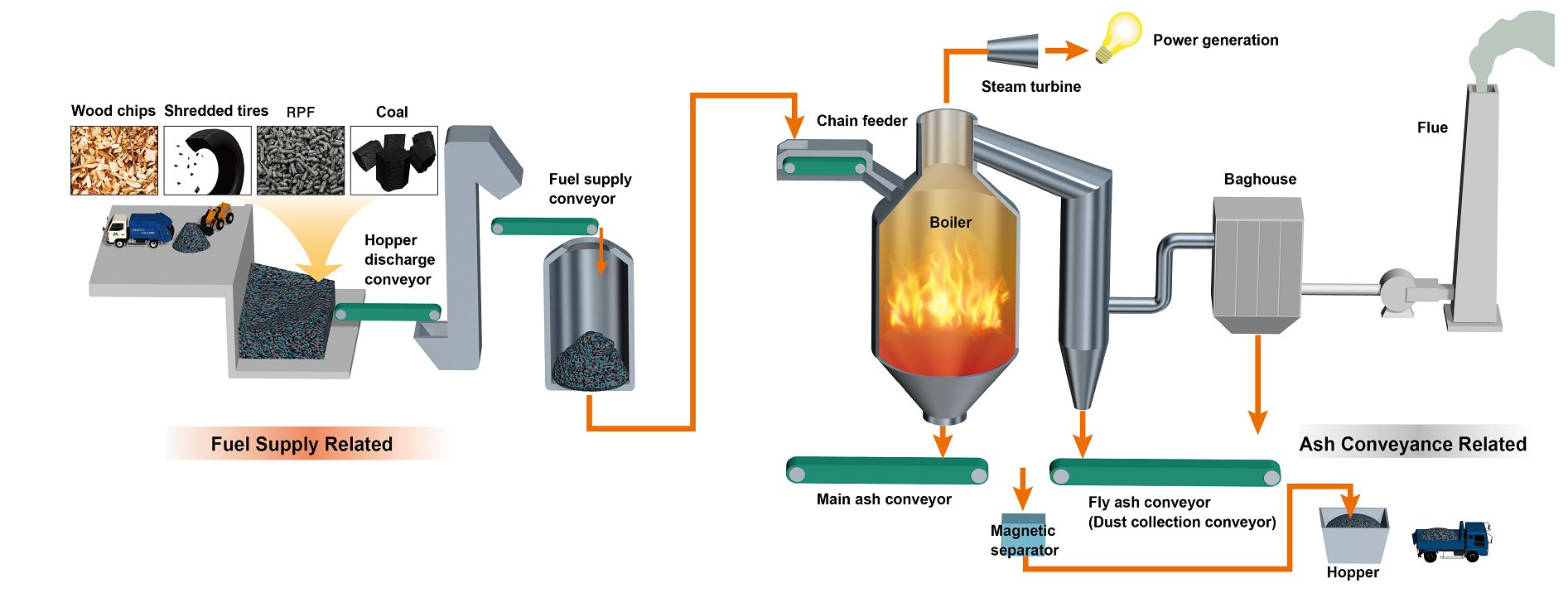

Biomass power generation facility

Waste Disposal Facility

Food Industry

Water Treatment Plant

Automotive

Cement Industry

Conveyor chains specialized for each process: "raw materials," "baking," and "finishing"

- Raw material process

- Firing process

- Finishing process

Reclaimer equipment

Reclaimer equipment

This chain is designed specifically for equipment that continuously scrapes loose stored materials and sends them to the next process. Heavy loads are applied, which can cause rapid wear on the rollers.

Reclaimer chains are specially designed to suit the transported materials and various conditions.

Apron Conveyor

Apron Conveyor

This chain is used on conveyors that transport raw materials, fuel, etc. on the apron. Dust and other particles can cause significant wear on the rollers.

| General (Basic model) |

Countermeasure specifications (Advanced model) |

|

|---|---|---|

| short conveyor length | DT Series | DTA Series |

| short conveyor length | AT Series | ATA Series |

If you want to achieve an even longer lifespan, please consider a dust-resistant Bearing Roller Conveyor Chain.

Cake transport

Cake transport

When transporting dehydrated cake, the chain corrodes due to the impact of the transported material. As a corrosion prevention measure, stainless steel chains are often used.

Outdoor Conveyor

Outdoor Conveyor

This chain is suitable for conveyors used in environments exposed to wind and rain.

Clinker transport conveyor (drag conveyor)

Clinker transport conveyor (drag conveyor)

This drag chain is used to transport clinker. The front of the bushing pushes the material being transported.

Fuel transport

Fuel transport

This chain is used to transport various fuels, including highly corrosive materials such as coal and powdered coal.

・Powdered coal transport---Y specification

Flow Conveyor

Flow Conveyor

This is a special chain for transporting powder and granular materials in a sealed case. Various attachments are available to suit the transported material.

・General

・For powdered coal

・Fly ash transportation

Bucket elevator

Bucket elevator

This chain is used to lift and transport powder and granular materials in a sealed case, with emphasis on wear resistance and fatigue strength.

・General

・For powdered coal

・Fly ash transportation

Product Delivery

Dust collection conveyor

Dust collection conveyor

・General

・Measures against corrosive environments and poor bending

・Measures to prevent roller rotation failure

We also propose optimal clearance setting specifications.

Special sprocket block with replaceable teeth

Special sprocket block with replaceable teeth

Special sprocket for conveyors in environments where wear is severe or replacement is difficult.

Steel industry (transportation of ultra-heavy objects)

"Heavy loads," "high speeds," "high temperatures"...Conveyor chains are used for a variety of purposes

- ①②Raw material yard

- ③Sintered ore plant

- ④ Iron making yard

- ⑤Rolling yard

- ⑥Product yard

- blast furnace

- Coke plant

- Cold rolling yard

①Continuous chain unloader

①Continuous chain unloader

A chain with buckets attached continuously unloads loose cargo from the ship.

Because the transport speed is fast and the load is high, a special unloader chain with reduced wear elongation is used.

②Chain scraper type reclaimer

②Chain scraper type reclaimer

This chain is designed specifically for equipment that continuously scrapes away stored loose materials and supplies them to the next process.

A large load may be applied, causing the rollers to wear out quickly.

Reclaimer chains are specially designed to suit the transported materials and various conditions.

③Sintered ore transport pan conveyor

③Sintered ore transport pan conveyor

High temperature materials are also transported using large, specially shaped conveyor chains.

We also manufacture dedicated conveyor chains that are suitable for transporting goods and corrosive environments.

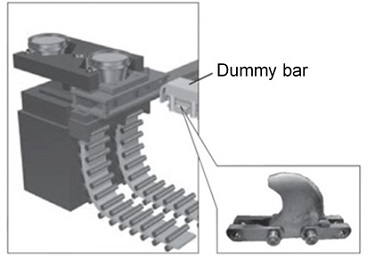

④Continuous casting process

④Continuous casting process

We will manufacture a chain to fit the shape of the dummy bar.

- Dummy Bar Receiver Chain

⑤Rolling process

⑤Rolling process

The chain is designed taking into consideration the shape, temperature, and transport atmosphere of the transported items.

For slab transport

For billet transport

For direct transport

⑥ Coil transfer

⑥ Coil transfer

Roller bearings are used between the rollers and bushings.

It reduces rolling resistance.

This allows for the transportation of heavy objects.

The saddle part is manufactured to suit the transport form.

High-temperature transport items [Steelmaking/Rolling]

High-temperature transport items [Steelmaking/Rolling]

Transporting high-temperature workpieces exceeding 400°C

Clearance settings and material selection according to the transported items and temperature

We manufacture special high-temperature conveyor chains.

Room temperature transport items [Steelmaking/hot rolling]

Room temperature transport items [Steelmaking/hot rolling]

Transporting heavy loads such as billets and coils

Billet and bar conveyor rollers wear out quickly

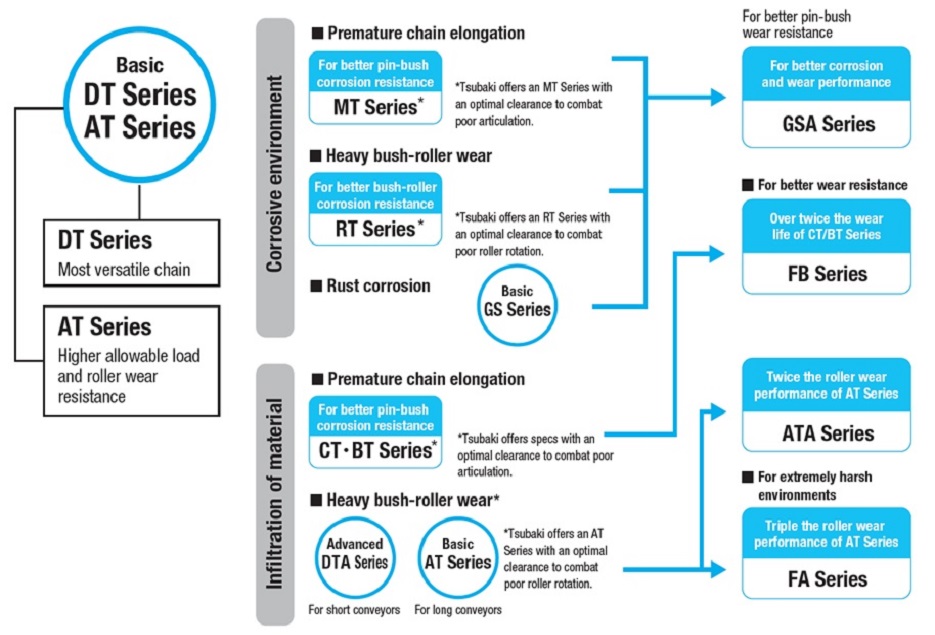

Biomass power generation facility

Conveyor chain for tough applications in biomass power plants

Waste Disposal Facility

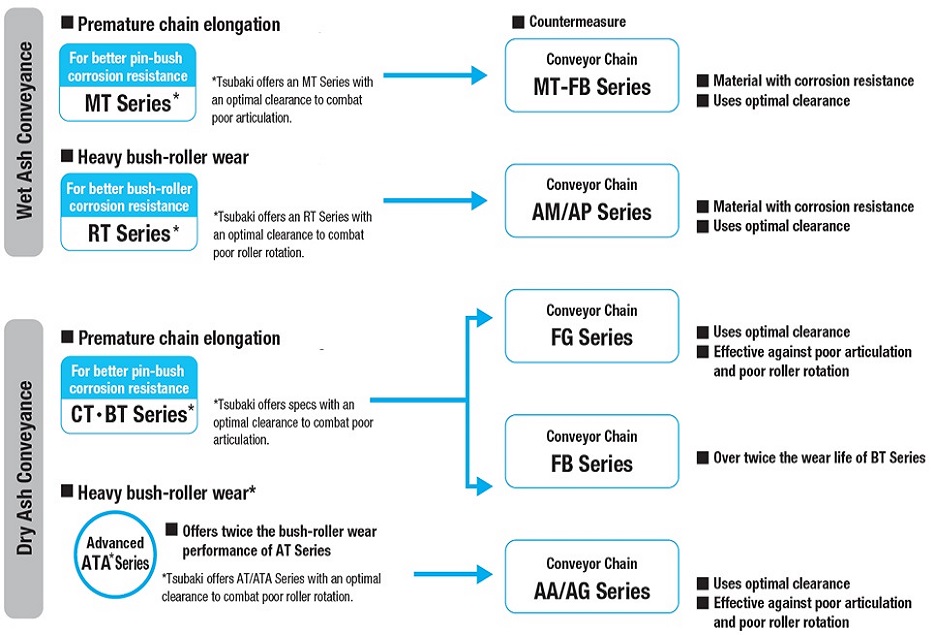

Conveyor chains that are ideal for the "harsh conditions" that vary from process to process.

- ① Receiving/supply conveyor

- ②Ash discharge conveyor

- ③Fly ash conveyor

- ④Molten slag conveyor

| ① Receiving/supply conveyor | ②Ash discharge conveyor | ③Fly ash conveyor | ④Molten slag conveyor | |||

|

This is the first line where collected waste is transported. Here, the waste may be subjected to shocks when it is put in and heavy loads from the transported items. For receiving and supply conveyors

・Transported items: Collected garbage |

This line transports ash after incineration. In some cases, it also transports ash that has been dropped into water for cooling after incineration. For ash removal (dry) conveyors

・Transported material: Ash after incineration For ash removal (wet) conveyors

・Transported material: Ash after incineration (containing moisture) |

This line transports fly ash generated after incineration or boiler use. The entire line is covered with fly ash. In some cases, it also transports fly ash that has been treated with additives. For fly ash (general) conveyors

・Transported material: fly ash after incineration For fly ash (contains corrosive) conveyor

・Transported items: Fly ash immediately after treatment with additives in a cooling tower, etc. |

This is a line that transports slag generated by the melting furnace. The slag can cause the water to become strongly alkaline or acidic. For molten slag conveyors

・Transported material: molten slag |

Food Industry

Conveyor chains that meet the diverse needs of the food industry

Grains and Feed

Flow Conveyor Chain for Grains

A specially designed flow conveyor chain that prevents grain from being crushed and ensures that no items are left behind inside the case.

meat

Chain for 3D overhead conveyors for meat transport

A specially shaped chain compatible with 3D layouts. Driven by a sprocket with a special tooth profile.

Frozen desserts and ice cream

Low temperature environment chain

This special chain prevents wear and elongation in low-temperature environments of -30°C, and moves in a spiral pattern inside the freezer for horizontal circulation.

food

Sterilizer chain

A dedicated chain with long conveyor length that can withstand harsh environments such as steam, cooling water, and air, with measures against stress corrosion cracking and wear elongation, and with reduced mutual differences between a pair of chains used in parallel.

bread making

Tunnel oven conveyor chain

A special chain that ensures wear resistance between bushing rollers even in temperatures of around 200°C, long conveyor length, and low speeds.

refined sugar

Conveyor chain for white sugar transport bucket elevator

This conveyor chain for bucket elevators reduces the generation of metal powder due to rust and wear. It also features an aesthetic specification that minimizes chain contamination.

beverage

Bottle washing machine conveyor chain

This special chain reduces wear even in detergent and water environments. It has earned high praise for its combination of materials and heat treatment to suit the customer's environment.

Product packaging

Product Packaging Conveyor Chain Lambda Plastic Roller Conveyor Chain

Even in places where lubrication is difficult, this conveyor chain can be used Lube-free, helping to maintain a clean environment.

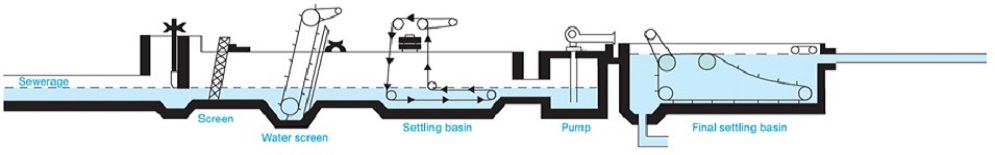

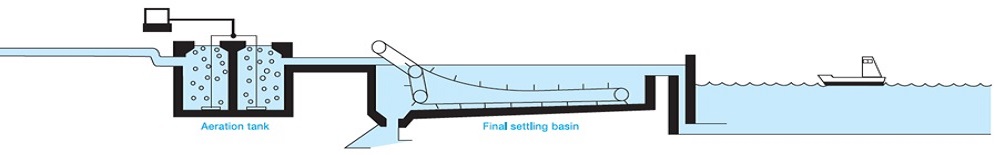

Water Treatment Plant

Water treatment system diagram

- Water screen

- Sand removal machine

- Sediment scraper

- Sand removal machine

- Sludge collector

- Drive chain

- Sludge collector

Automotive

Conveyor chains that meet various needs, including wear resistance, positioning, accumulation, heavy load capacity, jerking prevention, and long conveyor length.

press

press

Cutting, casting, forging, sheet metal pressing, resin molding, etc.

・Conveyor is subjected to impact

- Large wear between bushing and roller

(Advanced model)

・Improved wear resistance between bushing and roller

・Improved wear elongation and lifespan

Body welding

Body welding

Welding and assembly of roof and body panels

・Accurate positioning and transportation

need

- Needle bearings are used between the pin and bushing

coating

coating

Painting doors, bodies and other parts

・For towing dollies

- Dog-equipped conveyor chain

- For pallet stock

(For accumulation purposes)

- Free Flow Conveyor Chain

assembly

assembly

Car body transport, human conveyor

・Localized heavy load/long conveyor length

→ Large wear between bushing and roller

・Jerking occurs

→Workability decreases

- Bearing Roller Conveyor Chain

-cylindrical bearing are used between the bushing and roller

・Improved wear resistance between bushing and roller

- Rolling wear coefficient is 1/3

Stable, energy-saving, heavy load transport

We also offer conveyor chains that can be installed on low floors (300mm or less) even with long conveyor length and heavy loads.

inspection

inspection

Shower tester, final inspection wiping (optional installation) line

Shower tester/car wash line

It takes a lot of water

→Roller rotation failure

→ Abnormal wear of bushings and rollers

→ Rust

bearing roller

Water-resistant conveyor chain

・In an environment where water may splash

long life

Final inspection and wiping

(Optional installation) Line

Large loads are applied and conveyor length is long

→Roller rotation failure

→ Abnormal wear of bushings and rollers

- Reduces wear and jerking

Shower tester & final inspection line

<Roller type WDR/WDF>

Can be used in both wet and dry environments Lube-free

| Roller type WDR/WDF |

Bearing Roller Conveyor Chain | 【reference】 RT specifications (base chain) |

||

| Water Resistant Lube Free Series | Standard Specifications | |||

| shower tester | ○ | ◎ | × | △ |

| Inspection Line | ◎ | △ (Additional water lubrication required) |

◎ (No water splashes) |

△ (Lubricating required) |

| Roller rolling wear coefficient |

0.12 | 0.03 | 0.03 | 0.15 |

| remarks | Water + dry Lube-free realization |

For use as a shower tester Optimal |

Applications that may be exposed to water unsuitable |

SUS environment resistant chain |

◎: Optimal

○: Available

△: Can be used under certain conditions

×: Unusable

- I want to reduce chain wear elongation

- Want to extend the wear life of rollers

- Want to reduce chain wear and elongation in corrosive environments

- Want to extend the wear life of rollers in corrosive environments

I want to reduce chain wear elongation

Basic model

Upgrade STEP 1

Upgrade STEP 2

Basic model

Upgrade STEP 1

Upgrade STEP 2

Want to extend the wear life of rollers

Basic model

Upgrade STEP 1

Upgrade STEP 2

Improvement STEP 3

Conveyor Chain

Dedicated to transporting waste

Basic model

Advanced Model

Improvement STEP 3

Bulk item transport

Want to reduce chain wear and elongation in corrosive environments

Basic model

Upgrade STEP 1

Improved strength

Upgrade STEP 2

Improvement STEP1α

Advanced Model

Want to extend the wear life of rollers in corrosive environments

Basic model

Upgrade STEP 1

Improved strength

Upgrade STEP 2

Improvement STEP1α

Advanced Model

Improvement STEP 3

Toughroller

Model number TUF~

It consists of a frame body and endless rollers, and is attached to the center plate of the frame body.

Wrapped around an endless roller, it is ideal for moving, transferring and transporting heavy objects.

- - Steel roller type (basic load capacity 14.7kN to 1961kN)

The steel roller type is compact and has a large load capacity, with hardened center plate and rollers.

It's Toughroller. - -Plastic Roller type (basic load capacity 2.94kN to 34.3kN)

Plastic Roller type is Toughroller that uses engineering plastic (engineering plastic) for the roller. It adds the functionality of an engineering plastic roller to the basic features of a steel roller. In particular, the "Toughroller Jr." is an economical, lightweight, and simple type that is easy to use.

Size

Steel roller type

TUF-J to TUF200

Toughroller Jr.

TUF-JP

Plastic Roller type

TUF1P to TUF4P

Double roller type

TUF25W-ESP-TTB・TUF4WP-ESP-TTB

Axle Bearing Roller

Model number JB□□□-□~

Axle Bearing Roller has cylindrical bearing built into the roller.

Ideal for moving, transferring and transporting heavy objects.

- - Ideal for wheels, guide rollers, etc. when moving, transferring, or transporting heavy objects.

- - Grease specifications, grease-free specifications, water-resistant specifications, and heat-resistant specifications are available.

- ・JBR: R roller type

- ・JBF: F roller type

- ・JBFF: Double flanged roller

- ・JBTF: 5° tapered F roller type

- ・JBUR: Urethane roller

Chain specifications

Grease specification (standard specification),

Grease-free specification,

Water-resistant and heat-resistant

Size

JBR03~JBR36

JBF03~JBF36

Shaft type

Type 1, Type 2

Roller type

BR roller, BF roller,

BFF roller, BUR roller,

BTF roller

Attachment Bearing Roller

Model number AB□□□-□~

This is Attachment Bearing Roller has cylindrical bearing built into the roller.

- - Ideal for wheels, guide rollers, etc. when moving, transferring, or transporting heavy objects.

- - Grease specifications, grease-free specifications, water-resistant specifications, and heat-resistant specifications are available.

- ・ABR: R roller type

- ・ABF: F roller type

- ・ABFF: Double flanged roller

- ・ABUR: Urethane roller

Chain specifications

Grease specification (standard specification),

Grease-free specification,

Water-resistant and heat-resistant

Size

ABR03~ABR36

ABF03~ABF36

Roller type

BR roller, BF roller

BFF Roller, BUR Roller