Connecting Links for Large Size Conveyor Chain Screw Lock Link

- With just one torque wrench, anyone can easily, safely and reliably cut and connect.

- This connecting link makes it possible for anyone to easily perform the dangerous and technically demanding cut and connect of Large size conveyor chain with just a torque wrench.

- Traditionally, cut and connect was done using a hammer, but

- ·danger

Since you have to hit it hard with a hammer, there is a risk of industrial accidents such as flying fragments or hitting your hands. - ・Technology required

If not done properly, the outer plate may be pressed too hard, resulting in poor bending. - ・Man-hours required affect productivity

As mentioned above, it requires skill, so you may need to arrange for a technician. - ・Large tools are required

As the chain gets larger, larger tools and jigs may be required. - There were various challenges, such as:

- With Screw Lock Link, all you need to do is tighten the nut to the specified torque using a torque wrench, so anyone can perform cut and connect work easily, safely, quickly and reliably.

table of contents

Catalogs and Instruction Manuals

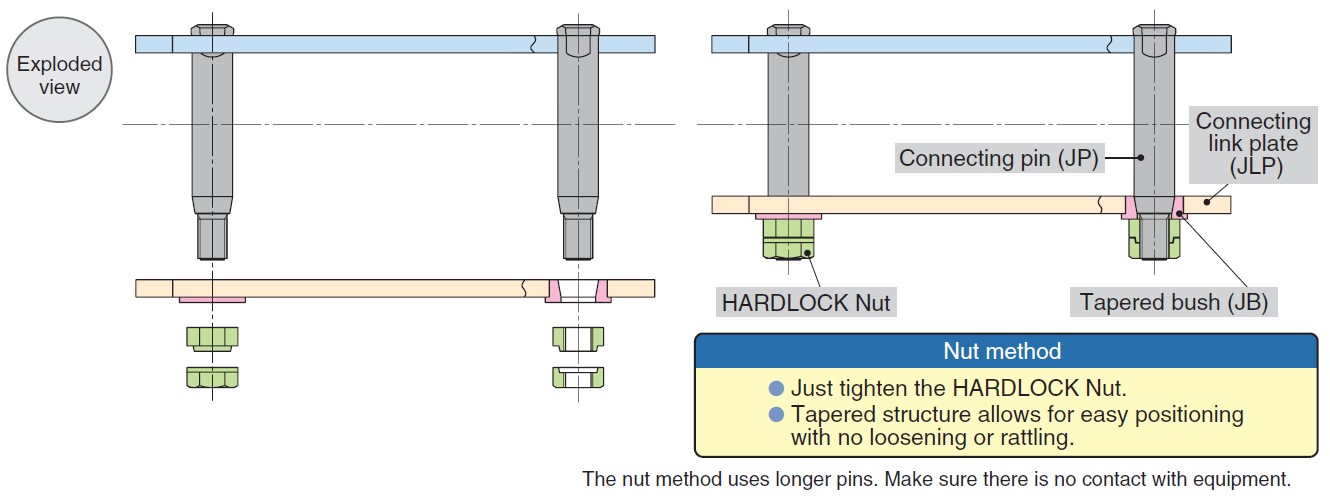

Structure

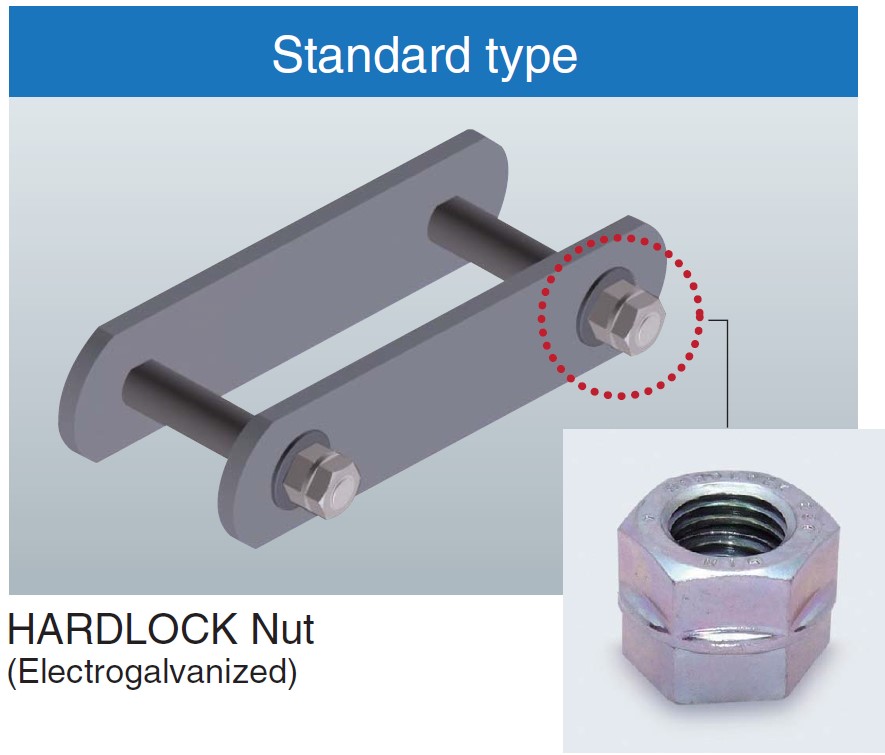

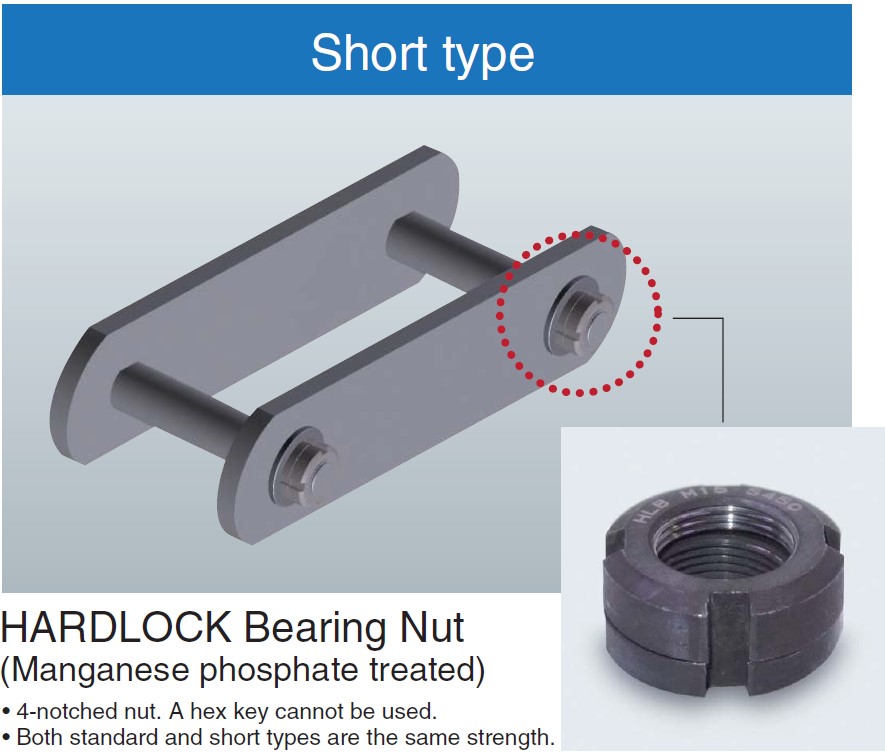

Two types of nuts available

We also offer a short type with the pin length minimized.

*Hardlock Nut and Hardlock Bearing Nut are trademarks or registered trademarks of Hardlock Kogyo Co., Ltd.

Main applicable products

Large size conveyor chain DT Series

The most economical general-purpose conveyor chain (basic model).

Large size conveyor chain DTA Series

Compared to the DT Series, wear resistance between the bush and roller is tripled.

Large size conveyor chain AT Series

Compared to DT Series, it has approximately twice Maximum allowable load, improving the wear resistance between the bushing and roller and the allowable load on the roller.

Large size conveyor chain ATA Series

Compared to AT Series, wear resistance between the bush and roller is doubled, wear resistance between the pin and bush is 1.5 times greater, and Maximum allowable load is 1.2 times greater.

Large size conveyor chain SS Series

This stainless steel chain has excellent corrosion resistance, chemical resistance, heat resistance, and cold resistance.

Large size conveyor chain GS Series

This is a stainless steel chain (stainless steel 400 series) with improved corrosion resistance compared to DT Series.

Please see below for other specifications that can be manufactured.

Handling instructions

| ⚠Caution |

For horizontal, inclined, and vertical conveyors, before cutting or cut and connect, use a chain block, wire, etc. to ensure that no tension is applied to the chain at cut and connect point. |

|---|

How to join

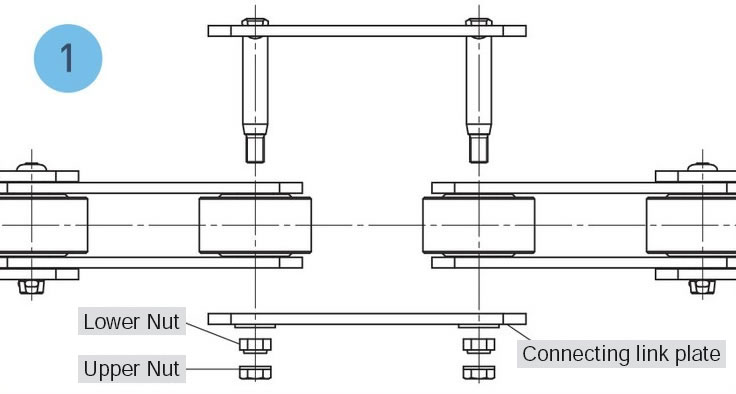

1. Remove the nuts and leave connecting link plate removed.

2. Pull both ends of the chain together, insert the connecting link into the joint of Inner link, and then cover it with connecting link plate.

3. Tighten the lower nut to the specified torque. When tightening the nut, be sure to wipe off any oil or other debris from the threads with a cloth.

4. Tighten the upper nut to the torque specified below to complete the connection.

Nut tightening torque (N・m) *1

| RF10 | RF12 | RF17 | RF26 | RF36 | RF52 | RF60 | RF90 | ||

|---|---|---|---|---|---|---|---|---|---|

| Standard type *2 | Nut Size | M12×P1.75 | M12×P1.75 | M14×P2.0 | M16×P2.0 | M20×P2.5 | M24×P3.0 | M27×P3.0 | M30×P3.5 |

| Lower nut | 27~32 | 28~33 | 46~55 | 72~82 | 120~130 | 218~228 | 250~260 | 367~377 | |

| Upper nut | 27~32 | 28~33 | 46~55 | 72~82 | 120~130 | 218~228 | 250~260 | 367~377 | |

| Short type *3 | Nut Size | M12×P1.0 | M12×P1.0 | M15×P1.0 | M17×P1.0 | M20×P1.0 | M25×P1.5 | M30×P1.5 | M35×P1.5 |

| Lower nut | 23~27 | 28~33 | 49~58 | 76~86 | 117~127 | 227~237 | 254~264 | 428~438 | |

| Upper nut | 16~19 | 16~19 | 28~33 | 37~44 | 55~65 | 80~90 | 115~125 | 130~140 | |

- *1. The above table shows the tightening torque for steel nuts. Please contact us for the tightening torque for stainless steel nuts.

- *2.When tightening the lower nut, the bolt will protrude, so we recommend using a deep socket for the standard type.

- *3. The short type is a 4-notch nut. Please use a hook wrench or socket.

How to cut

- 1. Remove the nuts in the order of upper nut and lower nut.

*The nut may not be easily removed due to adhesion or corrosion of the transported items. - 2. Remove connecting link plate and detach the connecting link from Inner link.

Maintenance and inspection precautions

Depending on the operating environment and conditions, the nuts may loosen or fall off, so be sure to check periodically to make sure they are not loose while the chain is in operation. (It will be easier to check if you mark the nuts with a marker.)

Product specifications list

Standard type

Short type

| size | Maximum allowable load | Minimum Tensile Strength | pitch P |

Pin | Nut Size | tapered bush Flange Diameter |

Approximate added mass (kg/place) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Joint pin | |||||||||||||

| DT kN{kgf} |

AT kN{kgf} |

DT kN{kgf} |

AT kN{kgf} |

L3 | standard type |

short type |

standard type |

short type |

A | standard type |

short type |

||

| L4 | L5 | ||||||||||||

| RF10100 | 17.6 {1790} |

32.3 {3290} |

107 {11000} |

169 {17000} |

100 | 33 | 48.5 | 42 | M12 | M12 | 25 | 0.13 | 0.08 |

| RF10125 | 125 | ||||||||||||

| RF10150 | 150 | ||||||||||||

| RF12200 | 26.6 {2710} |

39.9 {4060} |

160 {16500} |

249 {25500} |

200 | 40.5 | 55.5 | 49 | M12 | M12 | 28 | 0.17 | 0.11 |

| RF12250 | 250 | ||||||||||||

| RF17200 | 35.0 {3570} |

55.3 {5640} |

213 {22000} |

336 {34000} |

200 | 51.5 | 69.5 | 61.5 | M14 | M15 | 32 | 0.25 | 0.14 |

| RF17250 | 250 | ||||||||||||

| RF17300 | 300 | ||||||||||||

| RF26200 | 44.9 {4570} |

74.3 {7580} |

285 {29000} |

448 {45500} |

200 | 55.5 | 74 | 64 | M16 | M17 | 36 | 0.33 | 0.17 |

| RF26250 | 250 | ||||||||||||

| RF26300 | 300 | ||||||||||||

| RF26450 | 450 | ||||||||||||

| RF36250 | 68.0 {6930} |

97.4 {9930} |

457 {46500} |

614 {62500} |

250 | 66 | 91.5 | 78.5 | M20 | M20 | 42 | 0.55 | 0.26 |

| RF36300 | 300 | ||||||||||||

| RF36450 | 450 | ||||||||||||

| RF36600 | 600 | ||||||||||||

| RF52300 | 71.4 {7280} |

147 {15000} |

481 {49000} |

953 {97000} |

300 | 79 | 110 | 93.5 | M24 | M25 | 48 | 0.85 | 0.39 |

| RF52450 | 450 | ||||||||||||

| RF52600 | 600 | ||||||||||||

| RF60300 | 71.4 {7280} |

149 {15200} |

479 {49000} |

1010 {103000} |

300 | 72.5 | 104 | 86.5 | M27 | M30 | 55 | 1.18 | 0.53 |

| RF60350 | 350 | ||||||||||||

| RF60400 | 400 | ||||||||||||

| RF90350 | 113 {11500} |

233 {23700} |

754 {77000} |

1600 {163000} |

350 | 85.5 | 120.5 | 102 | M30 | M35 | 65 | 1.85 | 0.88 |

| RF90400 | 400 | ||||||||||||

| RF90500 | 500 | ||||||||||||

Note)

- 1. The operating temperature range is -20°C to 150°C. Please contact us regarding use outside this temperature range.

- 2. Pin lengths L4 and L5 are longer than L2, so please check for interference with the device.

- 3. Use a hook wrench or socket to tighten short type nuts.

- 4. Please refer to the "Tsubaki Large size conveyor chain & Sprocket" catalog for attachment types.

- 5. We may be able to manufacture sizes (inches, etc.) and specifications (stainless steel, etc.) other than those listed in the table above. Please contact us for details.

Price and delivery list

DT Series (standard type)

| size | attachment | |||||||

|---|---|---|---|---|---|---|---|---|

| none | A2 | K2 | GA2 | |||||

| Standard price | Delivery | Standard price | Delivery | Standard price | Delivery | Standard price | Delivery | |

| RF10100 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF10125 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF10150 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF12200 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF12250 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17200 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17250 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17300 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

AT Series (standard type)

| size | attachment | |||||||

|---|---|---|---|---|---|---|---|---|

| none | A2 | K2 | GA2 | |||||

| Standard price | Delivery | Standard price | Delivery | Standard price | Delivery | Standard price | Delivery | |

| RF10100 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF10125 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF10150 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF12200 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF12250 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17200 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17250 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

| RF17300 | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us | Please contact us |

Click here for a list of attachment types and symbols

*For specifications/sizes not listed in the table above, short types, and assembled products, quotes will be provided on a case-by-case basis, so please contact us.