Product Info Drive chain

Drive chains are also called roller chains.

Drive chains are mechanical elements that transmit the power of a motor or other driver as tension to a driven shaft via gear-like rotating elements called sprockets.

It consists of five parts: an inner plate, an outer plate, a pin, a bushing, and a roller, and is generally used for low-speed, heavy-load power transmission and hanging drives.

It has excellent features such as a large reduction ratio, high flexibility in shaft distance, and double-sided use for multi-axis shaft transmission. It also has long life, high strength, and corrosion resistance, making it suitable for use in a variety of situations.

Table of contents

Drive chain Related Information

-

Selection

-

Materials

-

Operation

Drive chain transmission features

- ・A large reduction ratio can be achieved (generally up to 1:7).

- ・Long shaft distances (usually 4m or less) are possible. Another feature is the high degree of freedom in shaft distance.

- - Both sides of the chain can be used, allowing for multi-axis shaft transmission.

- - Easy to install and replace (easy to cut and connect)

- - If the chain is supported with a short shaft distance, it can be driven even if the shaft is vertical.

- - Compared to belt drive, the sprocket diameter can be smaller for the same torque.

- - Since force is transmitted through a large number of teeth, wear on the sprocket teeth is more advantageous than with gears.

- - It has a higher shock absorption capacity than gears.

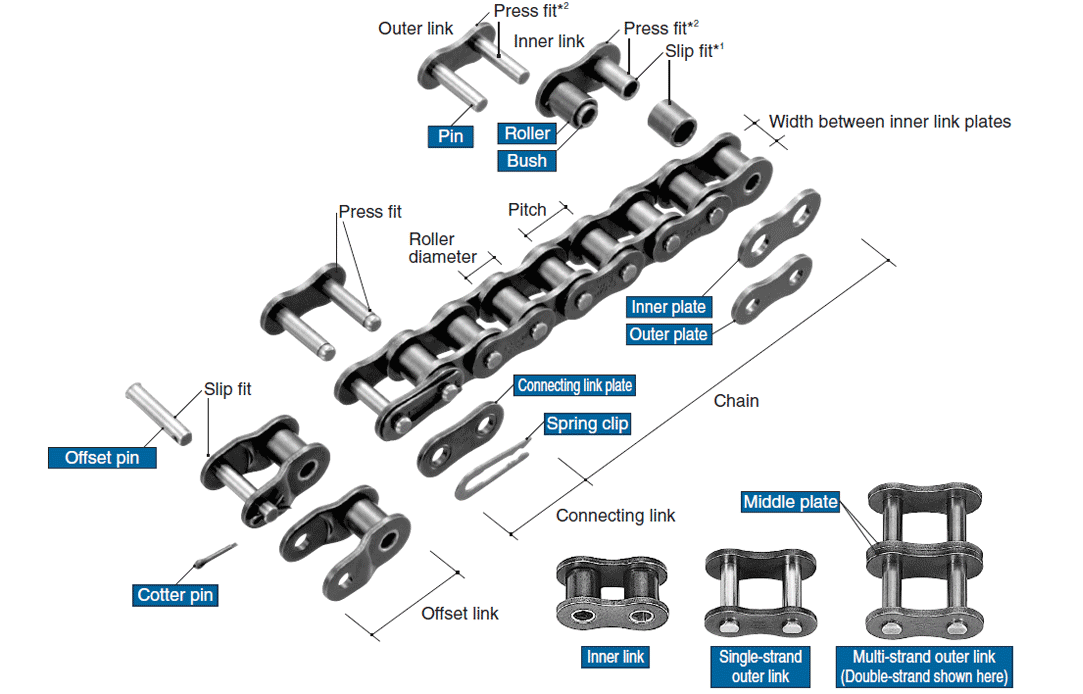

Structure

■The three basic dimensions of chains

Pitch, roller diameter, and inner link width are called the three basic dimensions of a roller chain. When these dimensions are the same, the roller chain and sprocket are dimensionally compatible.

*1 Slip fit

A fit that always has a gap when the shaft and hole are combined.

A fit in which the tolerance area of the hole is entirely above the tolerance area of the shaft (pin or bush).

*2 Press fit

A fit that always creates an interference when the shaft and hole are combined.

A fit in which the tolerance range of the hole is completely below the tolerance range of the shaft (pin or bush).

Learn more about the components and their functions

Learn more about the components and their functions

Plate

Plates are members that bear the tension applied to the roller chain during power transmission. This tension is usually a repeated load, but can sometimes be accompanied by impact. Therefore, plates are required to have not only static tensile strength, but also high fatigue strength, impact strength, and dynamic toughness.

Pin

The pins are subjected to shear and bending forces through the plate, and at the same time, when the roller chain bends and meshes with the sprocket, they form the bearing together with the bushing. Therefore, they need to have shear strength, bending strength, toughness, and wear resistance.

Bush

The bushing receives complex forces through various parts, but in particular, when it engages with the sprocket, it receives repeated impact loads through the rollers, so it must have high impact fatigue strength.In addition, it must be wear-resistant because it acts as a bearing when mated with the pin.

Roller

When the roller chain engages with the sprocket, the roller is subjected to repeated impact loads due to collisions with the front teeth. In addition, after engaging, the equilibrium position of engagement with the teeth changes depending on the magnitude of tension, so the roller moves along the tooth surface while being pinched between the teeth and the bushing, and is subjected to compressive loads and frictional forces. Therefore, impact fatigue strength, compressive strength, and abrasion resistance are required.

Note: RS11-SS, 15, 25, and 35 do not come with rollers.

Inner link

Two bushings are press fit fitted into two inner plates, and rollers are fitted to the outside of the bushings so that they can rotate. The same design is used for both single- and multiple-strand chains.

Outer link and intermediate plate

Outer link has two pins press fit into two outer plates. In the case of multiple strand roller chain, an intermediate plate is added to outer link. The intermediate plate of RS roller chain is slip fit (*1), while that of Super chain is press fit (*2).

Learn more about connecting parts

Learn more about connecting parts

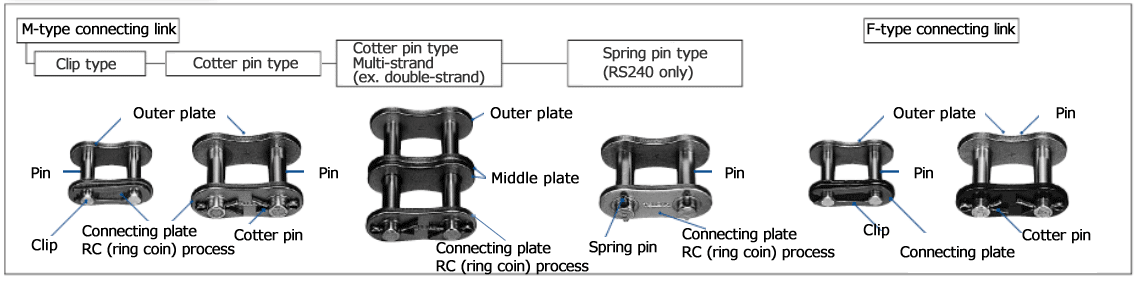

Roller chains are usually made up of many connected links and are used either as endless chains or with the ends fixed, but in either case a connecting link is required (and special connecting links are used for hanging applications, etc.). Also, if a roller chain has an odd number of links, offset links can be used, but it is best to design it with an even number of links whenever possible.

Connecting Link

| Chain Type | Connecting link name | Between pin and connecting link plate |

Connecting link plate Fastening method |

Precautions |

|---|---|---|---|---|

| RS roller chain | M-type connecting link Model: JL |

Slip fit (M) |

Spring clip pin Cotter pin Spring pin |

For multiple strand connecting links, install connecting link plate with RC processing (Note 3) on the outermost side. The operating speed is within the range indicated by the white area on kW ratings table. |

| F-type connecting link* Model: FJL |

Press fit (F) |

Spring clip Cotter pin Spring pin T-pin |

Be sure to use the product for the specified purpose and within the speed ranges indicated in the colored sections of kW ratings table. If you require an F-type connecting link, please be sure to specify this when ordering. |

|

| Lambda Chain | M-type connecting link Model: JL |

Slip fit (M) |

Spring clip Cotter pin |

Can be used across the entire range of Lambda Chain kW ratings table. Connecting link plate is RC processed. |

| Super chain | M-type connecting link Model: MJL |

Slip fit (M) |

Spring pin | Connecting link plate is RC processed. |

| F-type connecting link Model: FJL |

Press fit (F) |

Spring pin | Use in harsh conditions such as transmissions with large impacts, especially transmissions with large loads or where side forces may be applied. | |

| Super-H chain Ultra Super chain |

F-type connecting link Model: JL |

Press fit (F) |

Spring pin | Please use the dedicated connecting links for each chain. |

| RS-HT chain | M-type connecting link Model: MJL |

Slip fit (M) |

Split pin Spring pin |

Connecting link plate is RC processed. Use the special connecting links for RS-HT chain. |

| F-type connecting link* Model: JL |

Press fit (F) |

Split pin Spring pin |

Use the special connecting links for RS-HT chain. | |

| Catalogue description Other roller chains |

M-type connecting link Model: JL |

Slip fit (M) |

Cotter pins and spring clip Spring pin T-pins and Z-pins |

Please refer to the dimension diagram for each chain. Please note that only NP, NEP and SNS chains have RC processed connecting link plate. |

| Note) | |

| 1. | Connecting link plate fastening style for each chain size is as shown in the dimension drawings and respective notes. |

| 2. | *Only the F-type connecting link plate for RS roller chain and RS-HT chain have a black exterior color. |

| 3. | Ring coin (RC) processing is a unique Tsubaki process that creates a plastically deformed area along the pin hole in the connecting link plate, with the aim of generating residual stress around the hole.Even with slip fit, there is no reduction in strength and the chain can be used with the same strength as the main chain. |

Ring coin processing

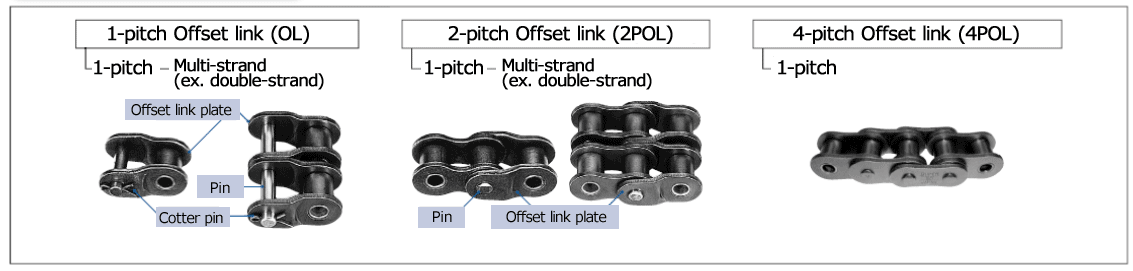

Offset Link

| Note) | |

| 1. | Please refer to the dimension drawing for the types and sizes of roller chains that can be used with offset links. |

| 2. | The transmission capacity and maximum allowable load of offset links may be lower than that of the main chain. |

Drive chain product list

- General-purpose Drive chain

- Lube-free Drive chain

- Heavy duty drive chain

- Environmentally resistant Drive chain

- Miniature Drive chain

(Miniature roller chain) - Special Chain

- Drive Chain Accessories

Lube-free and long life significantly reduces maintenance man-hours and costs

Lubrication is extremely important in chain transmission, and oiling can reduce wear and elongation between the pins and bushings at bending points.

Tsubaki Lambda Chain is the first in the industry to use special oil-impregnated bush, which eliminates the need for chain lubrication.

In applications where chain oiling is not possible, the frequency of chain replacement can be significantly reduced, reducing the amount of waste generated.

There is no contamination of the equipment due to additional oiling, and a clean work environment is maintained.

You can choose from a wide range of products, including Lambda Chain cold resistant series and other environmentally resistant chains, as well as Heavy-duty Lambda Chain.

The lubricant for special oil-impregnated bush has been improved.

special oil-impregnated bush are lubricated with NSF H1 compliant lubricant, so they can also be used in food processing machinery.

- *Please be aware that NSF H1 non-compliant rust prevention oil and assembly oil are also attached in the process of manufacturing.

- *NSF H1: NSF is an organization that certifies the safety of lubricants for food processing machinery.

- NSF H1 is a standard established by NSF that states, "Lubricants can be used in areas where accidental contact with food may occur."

Lambda Chain Structure

The inner plate thickness is one size larger, ensuring strength such as tensile strength. Therefore, the pin length is longer than that of general-purpose roller chains. Please check for interference with the equipment when replacing.

Lambda Chain

Model number RS□□-LMD~

Lube-free chain using special oil-impregnated bush

- -Due to the effect of special oil-impregnated bush, it can be used Lube-free.

- ・Maintenance man-hours can be reduced

- ・Compatible with RS roller chain. RS sprockets can be used.

- - The lubricant used for the oil-impregnated bushings is NSF H1 standard certified.

Size

RS40~RS160

Long Life Lambda Chain

Model number RS□□-LMDX~

Significantly improved wear resistance of Lambda Chain

- - The effect of special oil-impregnated bush and oil-impregnated felt seal provides an even longer life.

- - Compatible with Lambda Chain.

- - the lubricant used for the oil-impregnated bushings and oil-impregnated felt seals is NSF H1 certified.

Size

RS40~RS120

ラムダチェーン 耐寒仕様

Model number RS□□-LMDKT~

Lube-free chain that can be used in low-temperature environments

- - The minimum operating temperature limit for standard Lambda Chain specifications has been expanded to -30°C.

- -Can be used up to -30°C with the same transmission capacity as standard Lambda Chain.

- - the lubricant used for special oil-impregnated bush is NSF H1 standard certified.

Size

RS40~RS100

ラムダチェーン KF仕様

Model number RS□□-LMDKF~

Lube-free chain that can be used in high-temperature environments

- In addition to the specified temperature range of Lambda Chain, the operating range has been expanded to 230°C. Particularly suitable for temperatures between 150°C and 230°C.

- - the impregnating oil used is NSF H1 standard certified and can withstand High temperatures.

Size

RS40~RS80

ラムダ 強力チェーン

Model number RS□□-LMDH~

High-strength Lube-free chain

- ・By making the outer plate one size thicker, the transmission capacity is increased to a level higher than that of double-strand Lambda Chain.

- - the lubricant used for special oil-impregnated bush is NSF H1 standard certified.

Size

RS40~RS100

ラムダ コーティングチェーン NP仕様

Model number RS□□-LMDNP~

Lambda Chain with improved corrosion resistance thanks to coating

- NP Series: Special nickel plating is applied to the inner and outer plates and rollers, providing mild corrosion resistance.

- - the lubricant used for special oil-impregnated bush is NSF H1 standard certified.

Size

RS40~RS160

ラムダ 強力チェーン NP仕様

Model number RS□□-LMDHNP-2~

Heavy-duty Lambda Chain with mild corrosion resistance

- ・The plates and rollers of Heavy-duty Lambda Chain are specially nickel plated for mild corrosion resistance.

*Only available in two-row configuration. - · Even with the double-strand specification, it has the same strength as a general-purpose roller chain.

- -The sprocket is a special item.

Size

RS50-2~RS100-2

ラムダチェーン BS/DIN規格

Model number RS□□B-LM~

Lambda Chain that complies with European standards

- -Lambda Chain that complies with the ISO606 standard B series (European standard, BS/DIN standard).

- - It is possible to replace the existing BS standard roller chain.

- - The lubricant used for the oil-impregnated bushings is NSF H1 standard certified.

Size

RF06B~RS24B

ラムダ カーブドチェーン

Model number RS□□-LMCCU~

Lube-free chain that bends widely in the lateral direction

- -This chain allows for curved transmission by taking into account the clearances at each part, allowing for large lateral bends.

- - The lubricant used for the oil-impregnated bushings is NSF H1 standard certified.

- -RS sprockets can be used as is.

Size

RS40~RS60

ラムダチェーン 2列RS互換仕様

Model number RS□□-LMDS-2~

The standard RS sprocket for two rows can be used as is.

- This chain has the same transverse pitch as a double-strand RS roller chain, allowing use with double-row RS sprockets.

(Standard Lambda double-strand sprockets are required.) - - Transmission capacity is improved by approximately 20% compared to the standard 2-strand Lambda Chain.

- - The lubricant used for the oil-impregnated bushings is NSF H1 standard certified.

Size

RS40~RS160

Points to note when considering and adopting Lambda Chain

- 1. Foreign matter contamination prevention: Do not use the chain in cases where it comes into direct contact with food or where there is a risk that peeling debris or wear debris may get into the food.

Even when using in environments other than food where peeling debris or wear debris is a problem, please take measures to prevent foreign matter from entering, such as by installing an appropriate cover.

Nickel plating is not subject to regulation under the Food Sanitation Act or the Industrial Safety and Health Act, but please be careful if you are concerned about the plating peeling. - 2. Regarding product oil: Depending on the conditions of use, the oil impregnated in the bushings may splash out.

Due to manufacturing reasons, Lambda Chain has a small amount of oil on it that is not NSF H1 compliant.

If the oil impregnated in the bushing is lost, it will rapidly run out of oil, leading to wear elongation and the end of its life. - 3. If dust or other debris is present in the operating environment, the product may wear out and reach the end of its service life earlier than expected.

Do not use the bushing in an environment containing chemicals, solvents, or degreasing agents that may remove the oil impregnated in the bushing, or in water or under vacuum.

Lambda Chain is not coated with anti-rust oil, so please store it away from high temperatures, humidity, and dust. - 4. Regarding double-strand chains: transverse pitch of Lambda Chain and Heavy-duty Lambda Chain (including coated and KF Series) differs from that of RS roller chain.

Please use the dedicated sprocket instead of the RS sprocket.

RS Double Strand Compatible Lambda Chain has the same transverse pitch as RS roller chain. RS double-strand sprockets can be used.

LMD-2 and LMDS-2 chains cannot be used together, including connecting parts such as connecting links. When replacing the chain, please select a compatible sprocket. - 5. Check for interference with the equipment. The pin lengths for Lube-free chains vary depending on the thickness of the outer and inner plates and whether or not a felt seal is used.

The pins are longer than those of RS roller chain, so please check for interference with equipment when replacing.