Chain tensioner

- Adjusts chain slack to maintain normal chain transmission

- A large amount of chain slack can cause vibration and noise, and can lead to poor meshing with the sprocket, preventing smooth chain transmission.

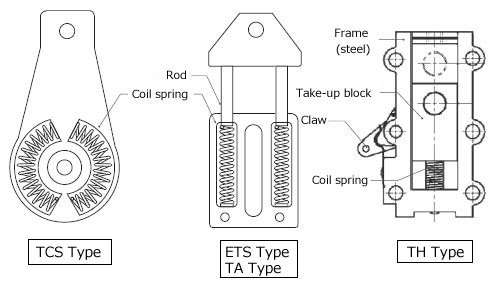

- We offer a lineup of four types of chain tensioners to eliminate chain slack: TH, TCS, ETS, and TA.

| ※ | CAD data will be provided via a link to CADENAS Web2CAD Co., Ltd.'s CAD Drawing Library site "PARTcommunity." |

| ※ | For inquiries about CAD data and PARTcommunity, please contact Cadenas Web2CAD. Cadenas Web to CAD Co., Ltd. TEL: (03)5961‐5031 FAX: (03)5961‐5032 |

Catalogs and Instruction Manuals

How to use a chain tensioner

We have four types available: TCS type, ETS type, TA type, and TH type.

Please see below for how to use each one.

Relationship between chain tensioner displacement and pressing force

- The main body of the chain tensioner contains two coil springs. The elasticity of these coil springs is used to press the idler sprocket or plastic shoe attached to the tip of the chain, adjusting the slack.

- Please refer to the formula below for the relationship between the displacement of the idler sprocket or plastic shoe and the pressing force acting at that time, and use it as a guide when installing and adjusting.

Structure

Tsubaki chain tensioners consist of a main body and an idler sprocket (the TA type is an integrated type with a plastic shoe).

The tensioner body (made of aluminum) is designed to perform tensioning using the elasticity of the built-in coil spring.

The idler sprocket section consists of a sprocket with a built-in bearing (an oil-less bush type is also available as an option for the TH type), mounting bolts and washers.

The sprocket teeth are induction hardened, the TCS and ETS types black oxide finish, and the TH type is plated.

Precautions for use

- - When the chain pulsates, the tensioner rod moves in and out in reaction, sliding against the main body. This accelerates wear on the rod and main body, so please lubricate it during this time.

- - The tensioner will be severely damaged in a dusty or corrosive environment. Avoid using it in such an environment.

- - Avoid using the tensioner in cases where thrust force is applied to it, such as in vertical drive, and where severe load fluctuations are applied, such as in forward and reverse operation, as this may cause severe damage to the tensioner.

variety

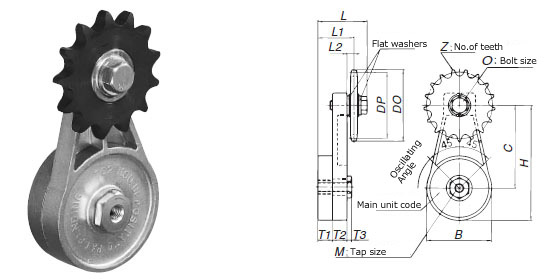

1. TCS Type (Oscillating Type) with Idler Sprocket

| Model number | Main unit code | Applicable chain |

swing angle |

Dimensions in mm | Pressing force kN { kgf } |

Estimated mass kg |

DXF Drawing 3D CAD data |

Standard price | Delivery | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | H | M | T1 | T2 | T3 | L | L1 | L2 | |||||||||

| CT-TCS40 | TC-1 | RS40-1 | 45゚ | 69 | 86.5 | 121 | M10 | 15.5 | 15.5 | 5 | 50.5 | 37.5 | 6.5 | 0 {0} ~ 0.15 {15} |

0.74 | DXF・3DCAD | Please contact us | Please contact us |

| CT-TCS50 | RS50-1 | 0.82 | DXF・3DCAD | Please contact us | Please contact us | |||||||||||||

| CT-TCS60 | TC-2 | RS60-1 | 30゚ | 90 | 100 | 145 | M12 | 18 | 18 | 7 | 60.5 | 44.5 | 8.5 | 0 {0} ~ 0.39 {40} |

1.3 | DXF・3DCAD | Please contact us | Please contact us |

| CT-TCS80 | RS80-1 | 65.5 | 47 | 11 | 1.52 | DXF・3DCAD | Please contact us | Please contact us | ||||||||||

| Model number | sprocket Number of teeth: Z |

DP mm |

DO mm |

Sprocket mounting bolt | Flat washer | |||

|---|---|---|---|---|---|---|---|---|

| Size: O | Length mm |

Strength classification | Nominal | quantity | ||||

| CT-TCS40 | 17 | 69.12 | 76 | M10 | 30 | 10.9 | 10 | 2 |

| CT-TCS50 | 15 | 76.35 | 84 | |||||

| CT-TCS60 | 13 | 79.60 | 89 | M12 | 35 | 10.9 | 12 | 2 |

| CT-TCS80 | 11 | 90.16 | 102 | 4 | ||||

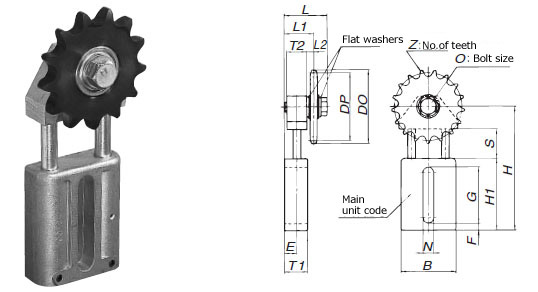

2. ETS type direct acting type with idler sprocket

| Model number | Main unit code | Applicable chain |

stroke S mm |

Dimensions in mm | Pressing force kN { kgf } |

Estimated mass kg |

DXF Drawing 3D CAD data |

Standard price | Delivery | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | H1 | F | G | B | N | T1 | T2 | E | L | L1 | L2 | |||||||||

| CT-ETS40 | TO-1 | RS40-1 | 30 | 129 | 74 | 7 | 58 | 56.2 | 11 | 23 | 20 | 12.5 | 42 | 29 | 6.5 | 0.10 {10} ~ 0.25 {25} |

0.6 | DXF・3DCAD | Please contact us | Please contact us |

| CT-ETS50 | RS50-1 | 0.69 | DXF・3DCAD | Please contact us | Please contact us | |||||||||||||||

| CT-ETS60 | TO-2 | RS60-1 | 38 | 163 | 87 | 9 | 70 | 70.5 | 12.5 | 28 | 25 | 15 | 52 | 36 | 8.5 | 0.15 {15} ~ 0.39 {40} |

1.15 | DXF・3DCAD | Please contact us | Please contact us |

| CT-ETS80 | RS80-1 | 57 | 38.5 | 11 | 1.37 | DXF・3DCAD | Please contact us | Please contact us | ||||||||||||

| Model number | sprocket Number of teeth: Z |

DP mm |

DO mm |

Sprocket mounting bolt | Flat washer | |||

|---|---|---|---|---|---|---|---|---|

| Size: O | Length mm |

Strength classification | Nominal | quantity | ||||

| CT-ETS40 | 17 | 69.12 | 76 | M10 | 35 | 10.9 | 10 | 2 |

| CT-ETS50 | 15 | 76.35 | 84 | |||||

| CT-ETS60 | 13 | 79.6 | 89 | M12 | 45 | 10.9 | 12 | 2 |

| CT-ETS80 | 11 | 90.16 | 102 | 4 | ||||

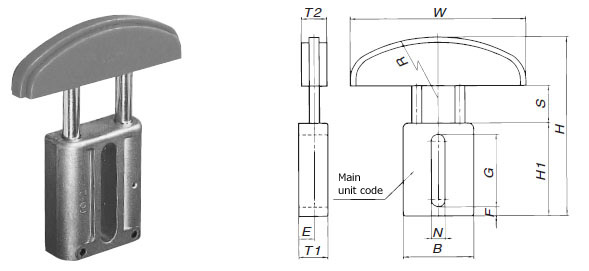

3. TA type direct acting type with plastic shoe

| Model number | Main unit code | Applicable chain |

stroke S mm |

Dimensions in mm | Pressing force kN { kgf } |

Estimated mass kg |

DXF Drawing 3D CAD data |

Standard price | Delivery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | H1 | F | G | B | N | T1 | E | W | R | T2 | |||||||||

| CT-TA40 | TO-1 | RS40-1 RS08B-1 |

30 | 143 | 74 | 7 | 58 | 56.2 | 11 | 23 | 12.5 | 140 | 120 | 20 | 0.10 {10} ~ 0.25 {25} |

0.39 | DXF・3DCAD | Please contact us | Please contact us |

| CT-TA50 | TO-2 | RS50-1 RS10B-1 |

38 | 164 | 87 | 9 | 70 | 70.5 | 12.5 | 28 | 15 | 140 | 140 | 22 | 0.15 {15} ~ 0.39 {40} |

0.65 | DXF・3DCAD | Please contact us | Please contact us |

| CT-TA60 | RS60-1 RS12B-1 |

DXF・3DCAD | Please contact us | Please contact us | |||||||||||||||

| CT-TA80 | TO-3 | RS80-1 RS16B-1 |

44 | 187 | 104 | 9 | 86 | 82 | 14.5 | 33 | 17.5 | 140 | 160 | 25 | 0.29 {30} ~ 0.59 {60} |

0.99 | DXF・3DCAD | Please contact us | Please contact us |

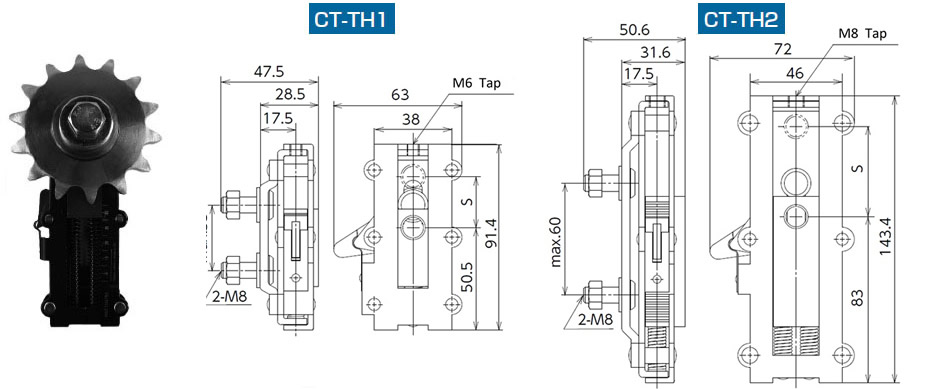

4. TH Type Linear type without idler sprocket

Main unit

Adapter (fixing base)

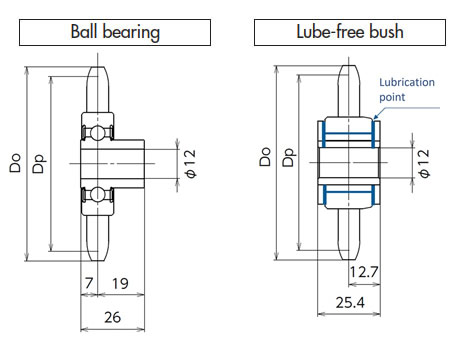

idler sprocket

| Model number | Idler Number of teeth |

Pitch Circle Diameter Dp mm |

Outer diameter Do mm |

Maximum Rotational speed r/min |

Bearing part allowable load N |

DXF Drawing 3D CAD data PDF Drawings |

Standard price | Delivery | ||

|---|---|---|---|---|---|---|---|---|---|---|

| ball bearings specification |

RS35-THB20T | 20 | 60.89 | 66 | 3000 | 3300 | DXF・3DCAD | Please contact us | Please contact us | |

| RS40-THB15T | 15 | 61.08 | 67 | DXF・3DCAD | Please contact us | Please contact us | ||||

| RS50-THB15T | 15 | 76.35 | 84 | DXF・3DCAD | Please contact us | Please contact us | ||||

| RS60-THB14T | 14 | 85.61 | 95 | DXF・3DCAD | Please contact us | Please contact us | ||||

| RS80-THB11T | 11 | 90.16 | 102 | DXF・3DCAD | Please contact us | Please contact us | ||||

| Oilless bushing specification |

RS35-THL20T | 20 | 60.89 | 66 | 2500 | 343 | DXF・3DCAD | Please contact us | Please contact us | |

| RS40-THL15T | 15 | 61.08 | 67 | DXF・3DCAD | Please contact us | Please contact us | ||||

| RS50-THL15T | 15 | 76.35 | 84 | DXF・3DCAD | Please contact us | Please contact us | ||||

| RS60-THL14T | 14 | 85.61 | 95 | DXF・3DCAD | Please contact us | Please contact us | ||||