Product Info Synchronous Belts and Belt Sprockets

Tsubaki Synchronous Belts are rubber belts with teeth and are also known as toothed belts.

By meshing the teeth on the belt pulley (gear), rotation can be transmitted reliably without slipping, unlike flat belts and V-belts, which transmit power solely through friction.

By embedding glass fiber, aramid fiber, or carbon fiber core wires inside, they have high tensile strength and are used in applications that require accurate positioning and high synchronization.

table of contents

Synchronous Belts related information

-

Selection

-

Materials

-

Operation

Synchronous Belts Features

-

High precision operation is possible.

The meshing transmission allows for accurate operation, and there is almost no belt stretch during operation.

-

Low noise.

It allows for quieter and smoother operation than other transmission elements such as gears.

-

It's a clean transmission.

No lubrication is required.

-

High efficiency.

It can efficiently transmit power from motors and other devices, with almost no energy loss.

-

High speed operation is possible.

Compared to other transmission elements such as gears, it is possible to operate at high speeds.

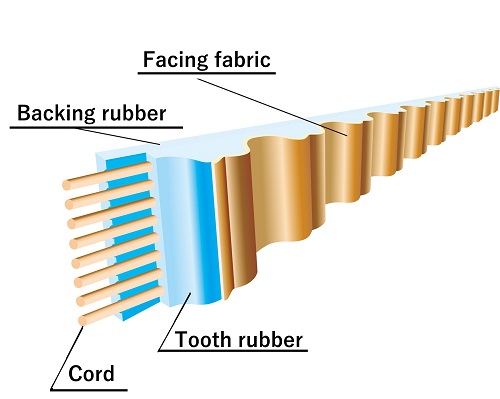

Structure

Backing rubber

耐久性、耐摩耗性を向上させた、クロロプレンゴム(または高強度合成ゴム)により、

心線を保護し長寿命を可能にしました。core wire

伸びが極めて少ない高抗張力グラスファイバー(またはアラミド繊維)を使用し、

高精度伝動を可能にしました。Tooth rubber

背ゴムと一体成形された歯ゴムは、高負荷のかみ合い伝動を可能にしました。Tooth fabric

耐摩耗性および自己潤滑により、スムーズなかみ合いと低騒音を可能にしました。

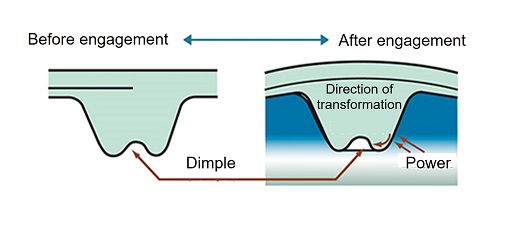

dimple

Low noise due to the effect of special dimples on the tooth tips.

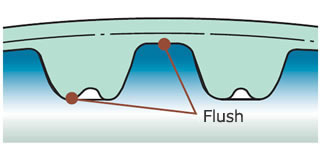

Just Touch Method

The just-touch method of engagement with the pulley, in which both the tooth tip and tooth root come into contact, enables high-precision transmission.

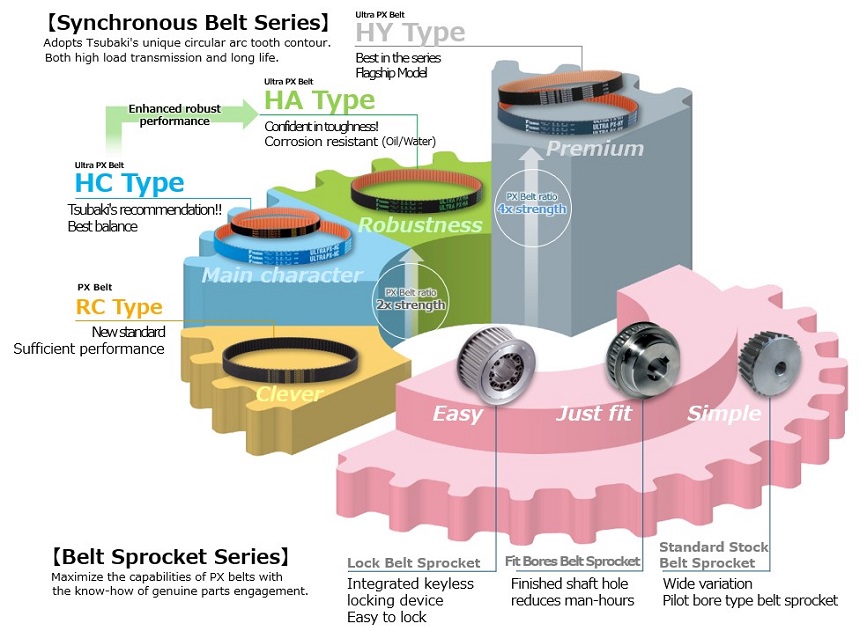

Synchronous Belts and Belt Sprockets lineup

Synchronous Belts and Belt Sprockets product list

Lock Belt Sprockets Pulley

Lock Belt Sprockets is Belt Sprockets with an integrated keyless fastener.

Friction locking eliminates backlash. Phase alignment, installation and removal are easy. No need for axial locking.

Depending on the application, you can choose from three types: the standard S type, the N type that can be fastened with one nut, and the C type that can be easily fastened with two bolts using a clamp collar.

S-type

C type

N-type

Lock Belt Sprockets S Type

Model number PT□□P□M□□□□-□S□□, PT□□L□□□□□-S□□

The most standard type of Lock Belt Sprockets

- - Strong fastening allows use with Ultra PX Belt

- ・Flat mounting makes it lightweight and space-saving

- - The pulley body is made of extra-super duralumin "S-type aluminum" and electroless nickel-plated type are also available.

- ・Effective in further reducing weight and inertia

size

P5M, P8M, P14M

Lock Belt Sprockets N Type

Model number PT□□P□M□□□□-N□□, PT□□L□□□□□-N□□

Easy to fasten with just one nut

- - Shaft hole diameters start from 7mm, making it ideal for fastening small shaft diameters.

- -This product is made to order.

- ・RoHS2 regulation (10 substances) compliant

- - The mounting position of the BF type pulley is different.

size

P3M, P5M

Lock Belt Sprockets C Type

Model number PT□□P□M□□□□-C□□

Lock Belt Sprockets with clamp collar

- - Easily fastened with two bolts. Excellent rotational balance, no pulley deformation, and compatible with small diameter shafts.

- -This product is made to order.

- ・RoHS2 regulation (10 substances) compliant

size

P2M, P3M, P5M