Double pitch Sprocket Fit bore BR Type

- Fit bore BR type is a sprocket with holes for mounting bearings.

- No additional work is required when installing bearings.

(Bearings not included) - Can be used as a driven sprocket or idler sprocket for conveyor chains, etc.

- Size Steel (S roller): RF2040 to RF2160

- Steel (R roller): RF2040 to RF2100

Catalogs and Instruction Manuals

Features

- - A lineup that allows you to choose from deep groove ball bearings, which are the most representative of rolling bearings.

- ・The model number can be used to specify the hole processing required to mount the bearing.

- - Eliminates the need for tedious drawing creation and arranging for additional work.

- - The housing hole is precisely finished, so you can insert a bearing after the product arrives and use it.

*Bearings not included

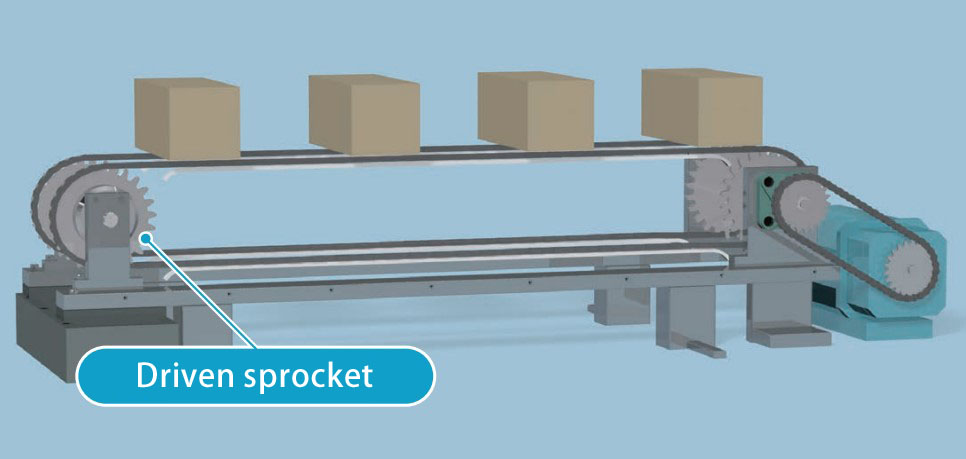

Usage example

Driven sprocket

- *When using a device with two or more chains and the driven sprocket is keyed, the phase of the sprocket teeth and key grooves must be precisely machined.

There may be variations in the amount of wear on the tooth surfaces of sprockets that are on the same axis. - By using a sprocket with bearings, keyway machining is not required, you can use it without worrying about phase, and installation is also easier.

- *Since there is no need to use an insert bearing unit, the device can be made compact.

idler sprocket

- *Idler sprockets are transmission parts that rotate when powered by the chain.

It adjusts the chain slack, transmits stable rotation, and maintains normal chain transmission.

Excessive chain slack can cause vibration and noise, and can lead to poor engagement with the sprocket, preventing smooth chain transmission.

Prevents sagging when the shaft distance is long

Intermediate idler for multi-shaft drive

When the chain winding angle is insufficient

Important points to note when selecting a sprocket

Please read the following precautions when considering using Fit bore BR type.

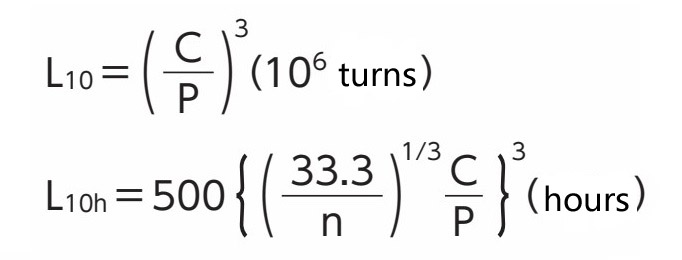

Bearing life calculations are based on the following conditions, so please use them as a reference.

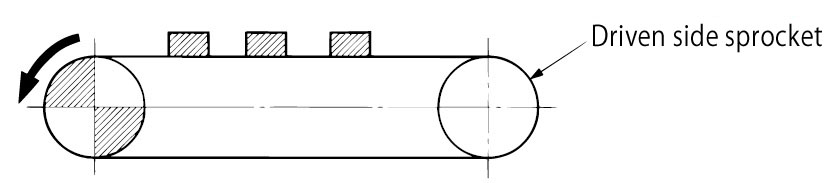

It is assumed that bearings will be used on the driven sprocket in a horizontal conveying layout.

- ・Conveying speed:

S roller: 20m/min

R roller: 30m/min

·load:

Half Maximum allowable load of the conveyor chain with attachments

・Bearings used:

deep groove ball bearing

*Calculation based on the basic rating life (L10) specified in JIS B 1518.

The basic dynamic load rating is calculated based on the values of domestic bearing manufacturers, assuming no axial load is applied.

C: Basic dynamic load rating [N]

P: Dynamic equivalent load [N]

n: rotation speed [r/min]

Image of horizontal transport

Fix the driven shaft to the device side.

*The safety factor for the basic static load rating is listed in the main dimensions list.

Precautions for use

About installation

*Housing hole tolerance is H7 finish.

We recommend that the shaft design conform to JIS standards.

[Reference] From JIS B 1566, "Tolerance range classes of shafts commonly used for radial bearings"

Shaft diameter Φ10 to Φ17: js5 Shaft diameter Φ20 to Φ70: k5

The strength of the shaft will vary depending on the application, so please determine it based on the general machine design.

*Make sure to secure the bearing firmly so that it does not move.

Examples of installation methods include fixing using collars, end plates, retaining rings, etc.

*If both inner race and outer race rings of the bearing have slip fit, clamp them in such a way that they sandwich the bearing, as shown in the "collar + end plate" diagram.

color

Collar + End Plate

retaining ring

Operating temperature

*The operating temperature range for the sprocket is -10 to 150°C.

Please check with the bearing manufacturer regarding the operating temperature range of the bearing.

Lubrication

* Always oil or grease the sprocket.

*For information on lubrication at high temperatures, please refer to the separate catalogs "Drive chain & Sprockets" or "Small size conveyor chain & Sprockets."

*Please lubricate the bearings to extend their lifespan.

If poor lubrication occurs due to deterioration of the grease, the lifespan will be significantly reduced.

Model number display example

Double pitch sprocket

| RF2060S-1B1012T | - | BR001 | - | H | 06007 | W | N | - | K | ||||||||||||||

| | Main unit model number |

| (1) Shape |

| | | |

| (3) "0" + bearing nominal number |

| | | |

| (5) No bearings installed |

| (6) Surface treatment |

|||||||||||||||||

| (2) Housing hole tolerance | (4) No. of strands | ||||||||||||||||||||||

|

|||||||||||||||||||||||

Product List

*Click to display detailed information.

| Size | Basic model number | Number of teeth | ||||

|---|---|---|---|---|---|---|

| 912T | 1012T | 1112T | 1200T | 1212T | ||

| RF2040S | RF2040S-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● |

| RF2050S | RF2050S-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● |

| RF2060S | RF2060S-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● |

| RF2080S | RF2080S-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● |

| RF2100S | RF2100S-1B□T■-BR001-H0□□□□WN | ● | ||||

| RF2120S | RF2120S-1B□T■-BR001-H0□□□□WN | ● | ||||

| RF2160S | RF2160S-1B□T■-BR001-H0□□□□WN | ● | ||||

| Size | Basic model number | Number of teeth | ||||||

|---|---|---|---|---|---|---|---|---|

| 1000T | 1100T | 1200T | 1300T | 1400T | 1500T | 1600T | ||

| RF2040R | RF2040R-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● | ● | ● |

| RF2050R | RF2050R-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● | ● | ● |

| RF2060R | RF2060R-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● | ● | ● |

| RF2080R | RF2080R-1B□T■-BR001-H0□□□□WN | ● | ● | ● | ● | ● | ● | ● |

| RF2100R | RF2100R-1B□T■-BR001-H0□□□□WN | ● | ||||||