Q&A linear actuator

We have posted frequently asked questions from customers in Q&A format. Please click on the question to proceed to the answer.

Linispeed Jack

Words in Q&Aof

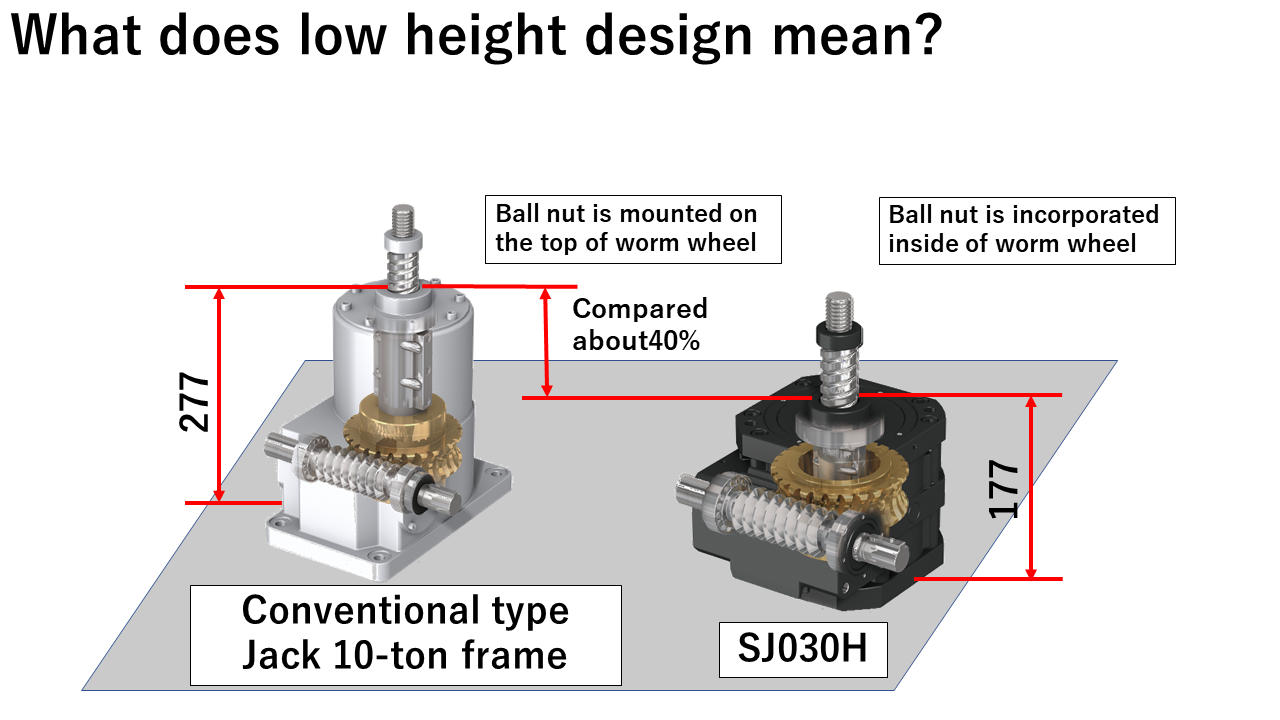

| Q1 | What does low-floor construction mean? |

|---|---|

| A1 | Conventional worm jacks have a structure in which a ball nut is placed on top of the worm wheel. |

| Q2 | Is 200mm/s faster than a typical worm jack? |

| A2 | With conventional worm jacks, the maximum speed is around 125 mm/s, although this depends on the frame number. |

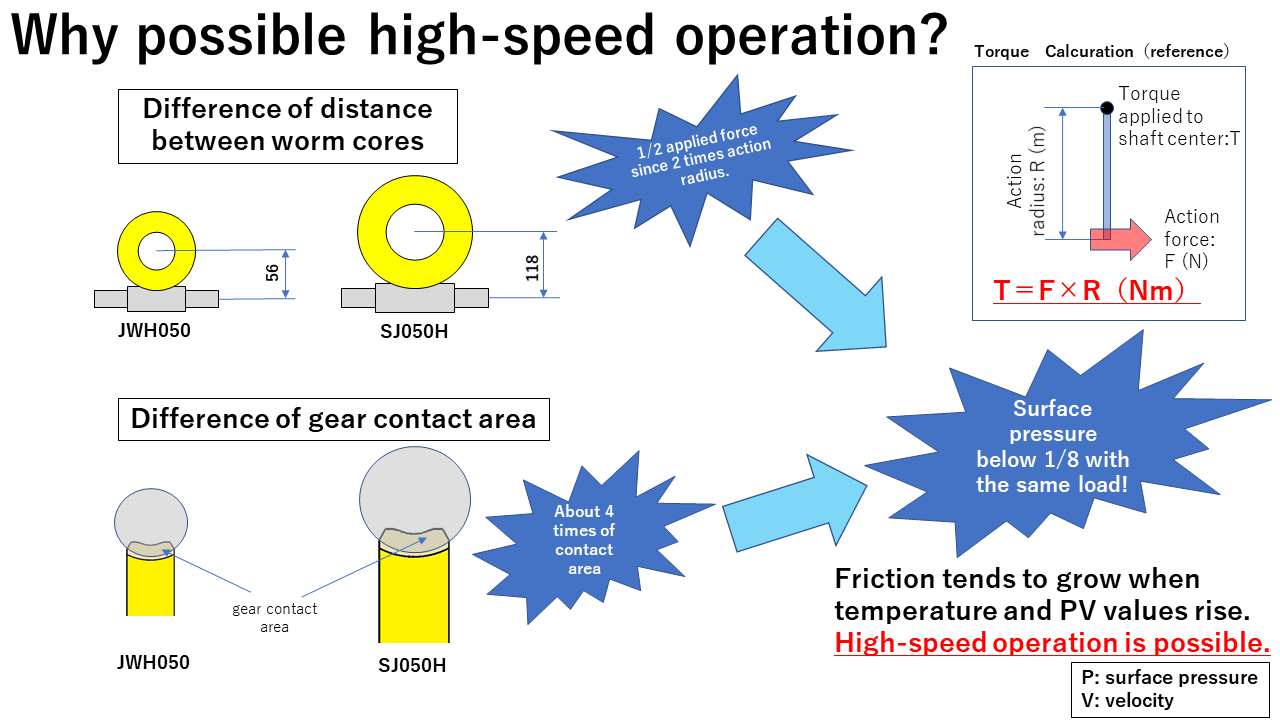

| Q3 | How can you drive at high speeds? |

| A3 | Linispeed Jack has a larger worm center distance than conventional models. |

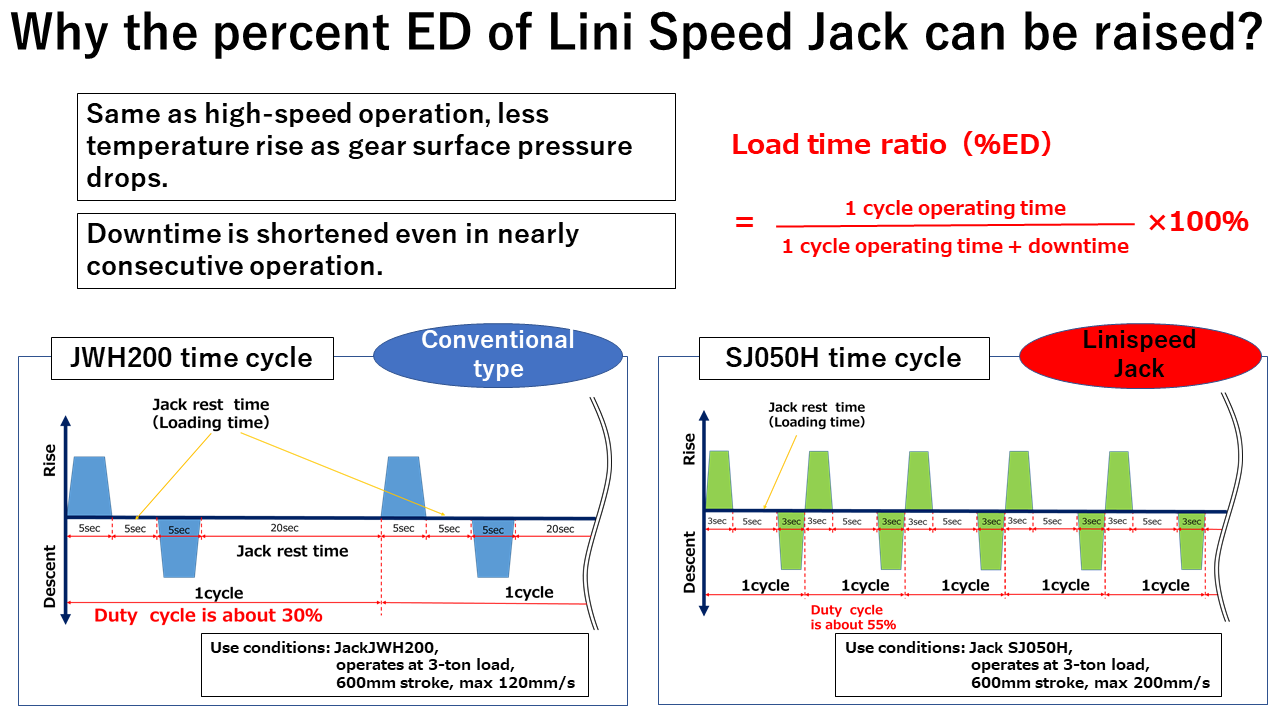

| Q4 | How can you increase Percentage duty cycle? |

| A4 | For the same reason as in the previous section, heat generation is suppressed, so if two 5-ton frames are used, Linispeed Jack will generate less heat and require less downtime. This results in a higher Percentage duty cycle than conventional types. |

| Q5 | Why does it have a long life? |

| A5 | It uses a more high performance screw than Ball screw used in general worm jacks. |

| Q6 | What are high-performance screws? |

| A6 | Due to confidentiality reasons, we cannot disclose the details, but by reviewing the materials used in comparison with ordinary Ball screw, we have achieved an expected travel distance of more than 10 times that of conventional jacks with the same frame size. |

| Q7 | Are there any thrust limits for conventional worm jacks? |

| A7 | With worm gears, as the input rotation speed increases, the allowable torque of the output shaft decreases. |

| Q8 | Why does the no-load idling torque of Linispeed Jack become so large? |

| A8 | First, the worm center distance is larger than that of conventional models, which increases the stirring resistance of the lubricating oil and the sliding resistance of the oil seal. |

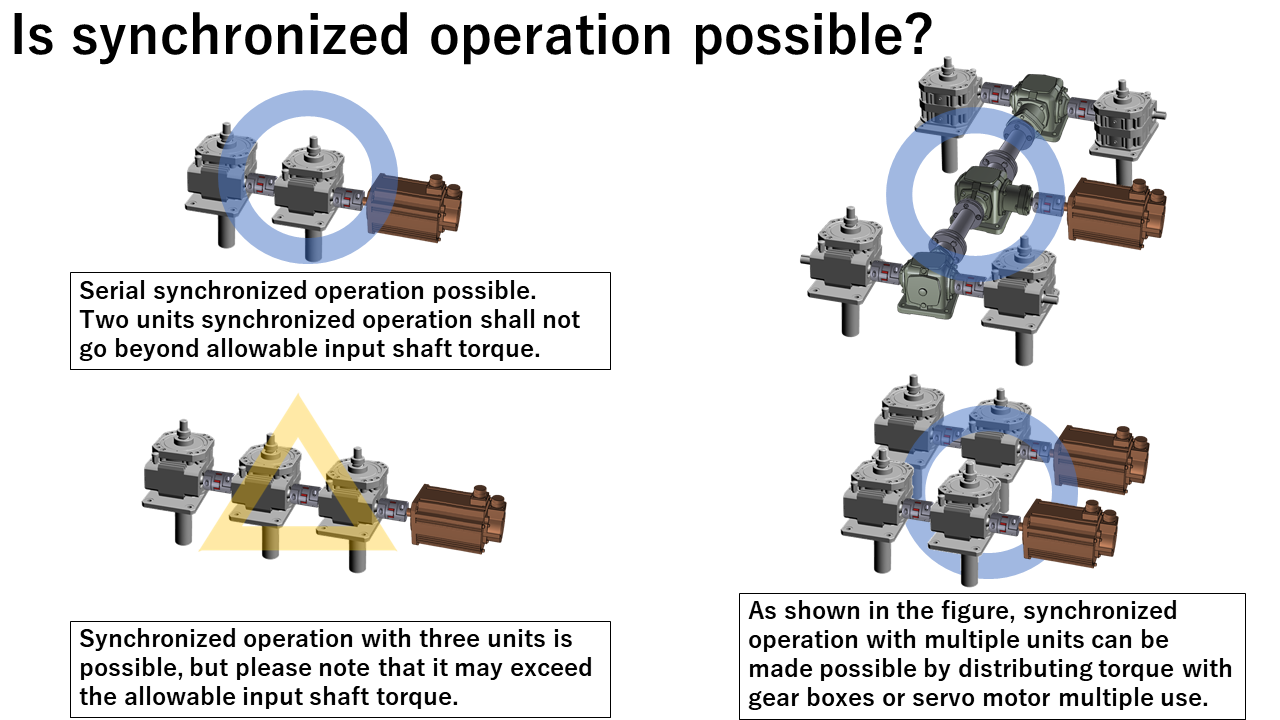

| Q9 | Is linked operation possible? |

| A9 | It is possible to link multiple units using couplings or Miter Gear Box. |

| Q10 | Does Linispeed Jack have a self-locking function? |

| A10 | Linispeed Jack do not have a self-locking function. |

| Q11 | Why the bellow of Lini Speed Jack is MTO item? |

| A11 | Since Linispeed Jack is designed for high-speed operation, the air flowing in and out of the jack using a standard bellows may not be able to keep up with the expansion and contraction, causing the bellows to burst. |

| Q12 | Can oil lubrication specifications be manufactured? |

| A12 | The gears of Linispeed Jack are oil lubricated as standard. |

| Q13 | Is it possible to manufacture gears with grease lubrication specifications? |

| A13 | It is possible to use grease lubrication, but the lubricity will decrease, so it cannot be used at the maximum speed or allowable frequency. |

| Q14 | Is it possible to use it in a clean room? |

| A14 | We can provide low-dust grease coating, Raydent treatment, and anti-rust plating on the input shaft. |

| Q15 | How do I view the allowable Percentage duty cycle table? |

| A15 | Select Percentage duty cycle table that you would like to use as a reference based on the model number and ambient temperature. |

| Q16 | Is it possible to flange mount a servo motor? |

| A16 | There are 176 size servo motors that can be combined, so please contact us. |