Zip Chain Lifter

- Scissor lifter with Zip Chain mechanism

- This is a revolutionary lifter that achieves unprecedented high-speed lifting.

- Zip Chain Lifter is a table-type lifter that uses Zip Chain to directly lift up the tabletop.

- Compared to hydraulic systems, it can move up and down 3 to 10 times faster. It is also suitable for high-frequency operation and can achieve energy savings of up to 50%.

What is Zip Chain?

- High-speed, high-frequency operation

- Multi-point stop function

- By far the most space-saving

Zip Chain is a chain developed exclusively by our company, in which two chains interlock like a zipper to form one strong pillar that can be pushed and pulled.

The Tsubaki Zip Chain Actuator is a commercialized linear actuator that uses this chain.

Compared to conventional pneumatic and hydraulic cylinders, they have many features, including environmental friendliness, such as space saving, high speed and high frequency operation, multi-point stopping function, high stopping accuracy, and freedom of installation direction, and are used in a wide range of applications from small actuators to large lifters.

Video content

Zip Chain and sprocket engagement

Zip Chain lifts the tabletop

1,000kg type

500kg 7m telescopic type

Features

Comparison with other organizations

| speed | High frequency | Stopping Accuracy | Expected lifespan | |

|---|---|---|---|---|

| Zip Chain Lifter | ◎ | ◎ | ◎ | ◎ |

| Electric screw lifter | × | × | ○ | × |

| Hydraulic Lifter | × | × | × | × |

Tsubaki's unique chain technology makes it possible to achieve excellent performance

2.5 times faster than hydraulic speed

Achieves high-speed operation with a maximum lifting speed of 100m/min.

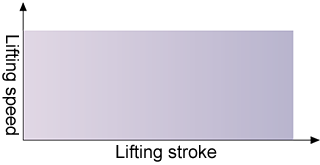

The mechanism directly pushes up the top plate at a stable speed, so it can be raised and lowered at a constant speed proportional to the motor's rotation speed.Synchronized operation of multiple units is also possible.

Zip Chain Lifter

Stable speed across the entire stroke range

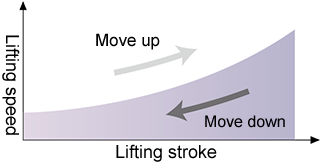

Hydraulic Lifter

The hydraulic cylinder extends and retracts diagonally to raise and lower the tabletop, causing the speed to change.

4.5 times the high-frequency hydraulic type

Zip Chain Lifter is similar to hydraulic lifters in that it operates more frequently.

There is no need to increase the tank capacity of the hydraulic unit.

In addition, it can achieve more than one cycle per minute, which is not possible with hydraulic or other methods.

Furthermore, continuous operation with multiple stops is also possible.

Stopping accuracy: hydraulic type is difficult to stop midway

Zip Chain Lifter's simple control configuration makes it easy to achieve multi-point stopping and multi-stage positioning.

Expected lifespan: 10 times longer than hydraulic type

Zip Chain Lifter has a mechanism that directly pushes up the top plate, so the load on the hinges and rollers is small, achieving a long life of over one million strokes.

Specification

- ・Allowable loading mass: 1,000kg/50kg

- ・Stroke: 1,000mm/1,600mm/300mm/500mm

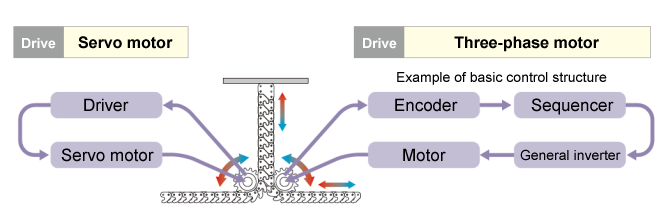

- ・Drive unit: with three-phase motor/servo motor

- ・Number of pantograph stages: 1 stage/2 stages

Catalogs and Instruction Manuals

Model number display

| ZSL | 1000 | L | 10 | G | 1 | - | T6 |

| | | Zip Chain Lifter |

| Allowable loading mass 1000: 1000kg 0050: 50kg |

| speed S: up to 6m/min L: 6 to 12 m/min M: 12-m/min |

| stroke 10: 1000mm 16: 1600mm 03: 300mm 05: 500mm |

| Drive unit G: With three-phase motor K: With servo motor |

| Number of pantograph stages 1: 1 step 2: 2 steps |

| option See below for details |

|

Product model number navigation

Allowable loading mass

The allowable weight of the load.

speed

This symbol indicates the lifting speed.

Please refer to the detailed information for the speed values of each model.

Stroke

The distance that can be raised or lowered.

Drive unit

G: Comes with a three-phase motor.

K: It comes with a servo motor.

Number of pantograph stages

It is a 1:1 stage pantograph type.

2: Two-stage pantograph type.

Option symbol

J: Bellows are attached to the opening.

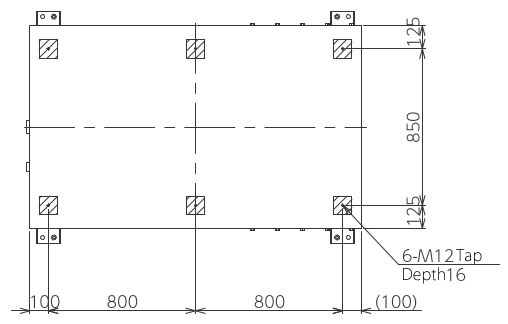

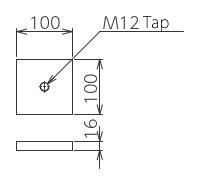

T6, T8: A fixing seat and tapped holes are provided on the top surface of the table.

(T6: 6 taps, T8: 8 taps)

V: This specifies the power supply voltage will be doubled.

E: A rotary encoder is attached to the rear of the motor.

Product model list [standard specifications]

*Click on the model number to display detailed information.

| Allowable loading mass kg |

stroke mm |

Drive unit | speed | ||

|---|---|---|---|---|---|

| 12~m/min | 6~12m/min | ~6m/min | |||

| 1000 | 1000 | G (with three-phase motor) | --- | ZSL1000L10G1 | ZSL1000S10G1 |

| 1600 | --- | ZSL1000L16G2 | ZSL1000S16G2 | ||

| 50 | 300 | --- | --- | ZSL0050S03G1 | |

| 500 | --- | --- | ZSL0050S05G2 | ||

| 1000 | 1000 | K (with servo motor) | ZSL1000M10K1 | --- | --- |

| 1600 | ZSL1000M16K2 | --- | --- | ||

| 50 | 300 | ZSL0050M03K1 | --- | --- | |

| 500 | ZSL0050M05K2 | --- | --- | ||

option

Full-circumference bellows [option code: J]

- A full-circumference bellows that prevents pinching in Zip Chain Lifter body.

*Special split types are also available, so please contact us for details.

| Stroke 1000mm Approximate mass: 35kg | Stroke 1600mm Approximate mass: 40kg |

|---|---|

Tap seat [option code: T6, T8]

- A fixing seat and tapped holes are provided on the top surface of the table.

| 6 taps: T6 | 8 taps: T8 | Tap detail: T8 |

|---|---|---|

|

Motor voltage 400V class [option code: V]

・Change the drive motor voltage to 400V class.

Compatible sizes: ZSL1000□□□G, ZSL1000M□□K, ZSL0050S□□G

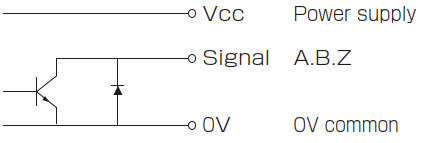

With rotary encoder [Option code: E]

- A rotary encoder can be installed on the shaft end of the non-load side of a three-phase motor, enabling the motor rotation signal to be output.

Compatible size: ZSL1000□□□G□

Features

・Controllability

An open collector output signal can be extracted from the reducer, allowing for a variety of operations.

·compact

There is no need to connect the motor shaft and rotary encoder with a coupling.

・Cost reduction

Compared to conventional separate installations, there is no need for couplings, base plates, or leveling work.

Rotary encoder specifications

| Power supply voltage | DC4.5~30V |

|---|---|

| Number of pulses | 100 |

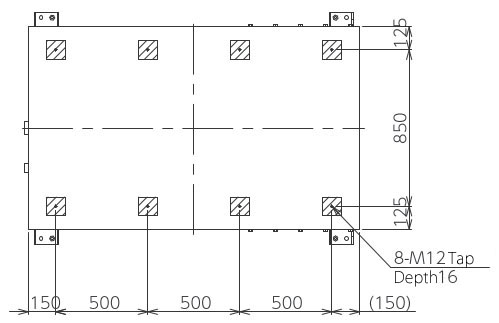

| Output format | Open collector output (NPN type) 6 AB90° phase difference signal +Z origin signal |

| Output Circuit | |

| Current consumption | 30mA or less |

| Output Voltage | 0.5V or less (At maximum sink current) |

| Maximum sink current | 40mA MAX |

| Signal rising Fall time |

1μs or less |

| Maximum Response Frequency | 240kHz |

| Output circuit withstand voltage | 50V MAX |

| Cable length | 0.5m with connector (Hirose Electric Co., Ltd. DF3-6S-2C) |

| vibration | 4.9m/s 2 {0.5G} or less (20~50Hz) |

Structure and dimensions (rotary encoder mounting part)

Wiring Table

| Pin No. | color | connection |

|---|---|---|

| 1 | red | power supply |

| 2 | black | 0V common |

| 3 | blue | Signal A |

| 4 | white | Signal B |

| 5 | yellow | Signal Z |

| 6 | black | shield |

Optional accessories sold separately

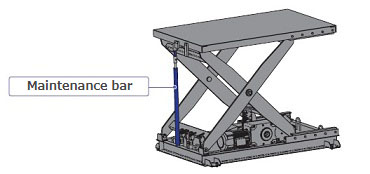

Maintenance bar

- If you are forced to put your body or part of your body under the tabletop frame during maintenance or inspection,

As a safety measure, be sure to use the maintenance bar.

- The ZSL0050 series comes with a maintenance bar, but the ZSL1000 series does not.

If you purchase the ZSL1000 series, please also purchase the optional ZSL1000 maintenance bar.

・The standard maintenance bar is used with a stroke of 1000 mm. Please contact us if you wish to use it with a different stroke.

| Model number | Applicable models | Standard price | Delivery |

|---|---|---|---|

| ZSL1000MB10 | ZSL1000~ | Please contact us | Please contact us |

Special specification products

400kg 2-stage pantograph type

External motor specifications:

Zip Chain with Two Prongs

2,000kg single-stage pantograph type

External motor specifications:

Zip Chain 4-Prong

300kg 3-stage telescopic type

External motor specifications:

Zip Chain with Two Prongs

650kg post type

External motor specifications:

Zip Chain with Two Prongs