Product Info Couplings (Shaft Couplings)

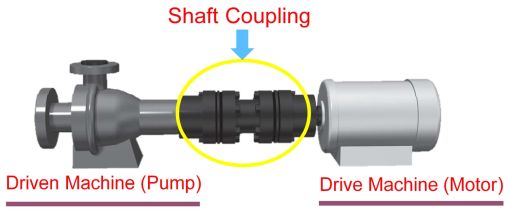

A coupling is a mechanical element used to connect the drive shaft and driven shaft and transmit the motor's power to the device.

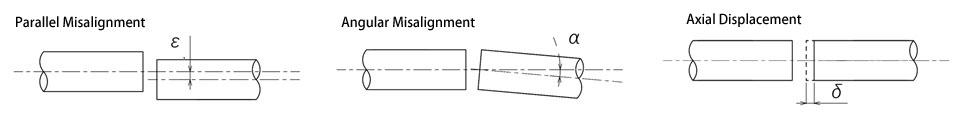

Couplings also play a variety of roles in connecting the drive shaft and driven shaft, such as absorbing misalignment (mounting error) between the shafts, reducing motor vibration, preventing the transfer of motor heat to the device, and preventing breakdowns in the motor or device due to damage to the coupling in the event of some kind of problem.

Table of contents

Coupling Related Information

What is a coupling (shaft coupling)?

- This is a part that connects the shaft (driver side) and the shaft (driven side).

A coupling is used to connect the shaft of a driving machine (such as a motor) and the shaft of a driven machine such as a pump, which are facing each other, and is also called a shaft coupling.

The role of couplings

Role 1: Transmits rotational force (torque) between in-line shafts.

Role 2: Absorbs mounting errors (misalignment).

Coupling product list

Chain coupling: Easy to connect and separate, large size lineup

A chain coupling is a flexible coupling in which a double-strand roller chain, made strong for coupling purposes, is wound around two sprockets.

It has excellent durability, can absorb large misalignments, and can be easily connected and disassembled by inserting and removing a single coupling pin.

We also offer an economy type that can be used for general transmission purposes, with a resin chain such as general-purpose linked polyacetal wound around the sprocket.

Roller chain coupling

Model number Body: CR□□□□H Case: CR□□□□K

This is a flexible coupling in which a double-strand roller chain is wound around two sprockets.

- The main body is made up of two rows of roller chains and two sprockets. The chain is connected by wrapping it around the sprockets and separated by removing it, so it can be connected and separated without moving the device.

- ・Excellent durability:

Rotational force is shared between the strong roller chain and the surface-hardened sprocket teeth, providing excellent durability.

It will be demonstrated. - ・Absorbs large misalignments:

The clearance between the components accommodates large misalignments on both shafts. - ・A wide variety of varieties:

In addition to the 15 varieties that comply with JIS standards, we have standardized 9 varieties, for a total of 24 varieties. - ·case:

Prevents lubricant from scattering and dust from entering, extending the life of the coupling (sold separately).

Applicable shaft diameter

Φ9.5mm~Φ700mm

Torque Range

99.9~717000N・m

Case

Sold separately

In the following cases, be sure to

Need a case

- Use at high rotation speeds

- Use in an abrasive atmosphere

- Use in a corrosive atmosphere

Roller chain coupling stainless steel series

Model number Body: CR□□□□H-SS Case: CR□□□□K-SS

Austenitic stainless steel is used for the roller chain and sprockets.

- ・Excellent corrosion resistance:

Suitable for use outdoors or in corrosive atmospheres such as acidic or alkaline. - ・Using temperature range:

Without case: -20 to 200°C With case: -10 to 80°C

*Please contact us if you plan to use the product with a case at temperatures exceeding 80°C. - ・Clean quality:

It has high rust prevention properties and is highly compatible with fluorine-based greases for food machinery and clean rooms. - ・Five large sizes added:

Five sizes have been added, from CR8018 to CR12022. - ・Quick delivery:

CR4012 to CR6022: 2 weeks for pilot bore products, 3 weeks for processed shaft holes.

CR8018 to CR12022: Both pilot bore and bore-machined products can be delivered in 4 weeks, and large sizes can also be delivered in a Quick delivery.

Applicable shaft diameter

Φ11mm~Φ140mm

Torque Range

74~5883N・m

Case

Sold separately

A case is required in the following cases:

- Use at high rotation speeds

- Use in an abrasive atmosphere

- Use in a corrosive atmosphere

Nylon chain coupling standard type

Model number CN□□□

This is an economy type with a resin chain such as polyacetal wound around the sprocket.

- ・Can be installed with a short center distance:

The structure is simply two sprockets connected by a nylon chain, so even if the distance between the two shafts is short,

The entire device can be made compact. - - Easy to put on and take off as it is a wraparound type:

Easy to assemble by wrapping the nylon chain around the sprocket and inserting the joint pin.

In addition, when performing maintenance on the equipment, it is possible to disconnect the drive and driven machines without moving them. - ・Torque can be increased without changing the overall length:

By increasing the number of teeth on the sprocket, the transmission torque of the coupling can be increased,

The coupling size can be increased without changing the center distance.

Applicable shaft diameter

10Φmm~Φ55mm

Torque Range

6.9~255N・m

nylon chain

Material: Polyacetal

Coupling pin material: Carbon steel

Color: White