Product Info Couplings (Shaft Couplings)

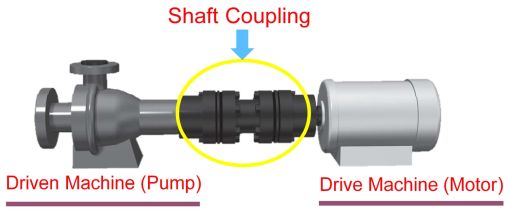

A coupling is a mechanical element used to connect the drive shaft and driven shaft and transmit the motor's power to the device.

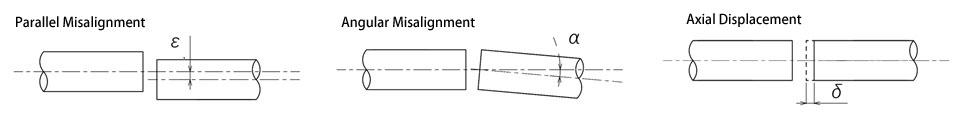

Couplings also play a variety of roles in connecting the drive shaft and driven shaft, such as absorbing misalignment (mounting error) between the shafts, reducing motor vibration, preventing the transfer of motor heat to the device, and preventing breakdowns in the motor or device due to damage to the coupling in the event of some kind of problem.

Table of contents

Coupling Related Information

What is a coupling (shaft coupling)?

- This is a part that connects the shaft (driver side) and the shaft (driven side).

A coupling is used to connect the shaft of a driving machine (such as a motor) and the shaft of a driven machine such as a pump, which are facing each other, and is also called a shaft coupling.

The role of couplings

Role 1: Transmits rotational force (torque) between in-line shafts.

Role 2: Absorbs mounting errors (misalignment).

Coupling product list

Jaw-Flex Coupling (Elastomer Coupling): Vibration absorption, misalignment absorption

Elastomer couplings have a simple structure consisting of two hubs and one elastic body (insert, spider), making them the easiest coupling to install and remove.

Tsubaki's elastomer couplings and Jaw-Flex couplings are available in the LN series, which is non-backlash and provides excellent shock absorption when starting and stopping and vibration countermeasures for servo motor drive, and the L series, which comes in a wide variety of versions and can be used for direct connection to general-purpose motors under light loads.

Jaw-Flex L Series

Model number L□□□S/M/H~

A light-load flexible coupling ideal for direct connection to general-purpose motors.

- ・Extensive standard stock of finished bore hubs:

With 63 types of hole processing and 499 combinations of hole diameters in stock, we can accommodate a wide range of shaft hole combinations.

- ・Ideal for direct motor connection:

The design is suitable for high speed and low torque and is compatible with all sizes of general-purpose motors. - ・Selectable inserts:

You can choose the insert depending on your application. Please refer to the details page. - ・Simple and compact structure:

It has a simple structure consisting of three parts and is compact.

It can be connected and disconnected simply by moving it in the axial direction. - ・Inexpensive:

This is the most economical coupling for direct motor connection, with thorough economical design. - ・Plated hubs and aluminum hubs are now standard:

The plated hub is compatible with urethane and Hytrel ® inserts, providing excellent corrosion resistance.

Aluminum hubs are also standard.

Applicable shaft diameter

Φ5mm~Φ69mm

Torque Range

0.4~711N・m

Insert Type

S-type = Nitrile

M type = urethane

H type = Hytrel

Backlash

Provided

Jaw-Flex LN Series

Model number L□□U98A1/64D1~

A new material has been used for the spider, achieving unprecedented vibration damping.

- - Servo motor drive provides excellent vibration countermeasures and shock absorption during start-up and shutdown.

- - The optimal combination of spider and hub allows torque to be transmitted without backlash, even though it is Jaw-Flex coupling.

- - You can choose from between two types of spiders: 98A excellent for vibration damping; and 64D with high torsional stiffness and wear resistance.

- ・The simple structure consisting of two hubs and one spider and the clamp-type shaft fastening system make installation easy.

It's extremely easy. - ・Taper lock fastening is also available. Please contact us. (Made to order)

Applicable shaft diameter

Φ12mm~Φ42mm

Torque Range

60~405N・m

Types of Spiders

98A1: Hardness 98A

64D1: Hardness 64D

Backlash

None