Product Info Couplings (Shaft Couplings)

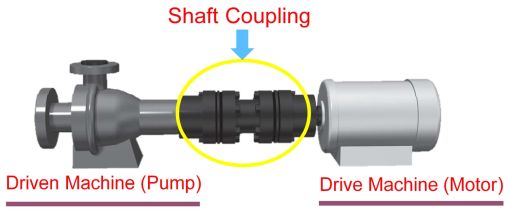

A coupling is a mechanical element used to connect the drive shaft and driven shaft and transmit the motor's power to the device.

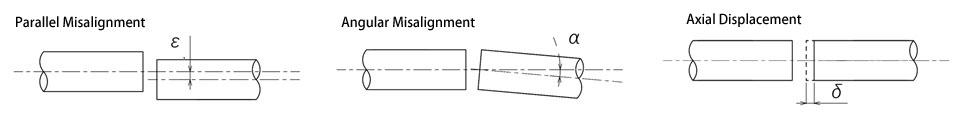

Couplings also play a variety of roles in connecting the drive shaft and driven shaft, such as absorbing misalignment (mounting error) between the shafts, reducing motor vibration, preventing the transfer of motor heat to the device, and preventing breakdowns in the motor or device due to damage to the coupling in the event of some kind of problem.

Table of contents

Coupling Related Information

What is a coupling (shaft coupling)?

- This is a part that connects the shaft (driver side) and the shaft (driven side).

A coupling is used to connect the shaft of a driving machine (such as a motor) and the shaft of a driven machine such as a pump, which are facing each other, and is also called a shaft coupling.

The role of couplings

Role 1: Transmits rotational force (torque) between in-line shafts.

Role 2: Absorbs mounting errors (misalignment).

Coupling product list

ECHT-FLEX Coupling (Disc Coupling): Flexible, highly rigid, and lubrication-free

A disc coupling generates axial force in the bolt by tightening the U-nut, and transmits torque through the friction force between the hub, washer, and disc.

Since there are no sliding parts, there is no lifespan due to wear, and since it is designed below the fatigue limit, it can be used for a long period of time.

Because it is a friction transmission, there is no backlash, it has high torsional rigidity, can be used without lubrication, and is ideal for connecting servo motors, stepping motors, etc.

Tsubaki's disc couplings and ECHT-FLEX couplings use discs with optimal shapes based on the finite element method to reliably transmit torque while flexibly absorbing misalignment.

Our product lineup includes the NER series, which uses a unique center unit structure that eliminates the need for customers to assemble disks, the NES series for small precision applications, the comprehensive general-purpose NEF series, and the large-capacity NEH series.

- * Discs are not consumables.

If the disc is damaged, it may be due to some kind of problem such as overload or excessive installation error (misalignment).

Disc couplings do not have a wear life due to friction transmission. Please consider the NER series, which comes with a pre-installed disc for easy assembly. - * Normally, please consider the spacer type.

The single type cannot absorb eccentricity (parallelism error).

| Spacer Type |  |

This type incorporates two sets of discs and can absorb all misalignments including Angular Misalignment, parallel error, and axial displacement, allowing for the widest range of use. |

|---|---|---|

| Single type |  |

t has one set of discs and only absorbs Angular Misalignment and axial displacement. It cannot absorb Parallel Misalignment, so it is recommended only for installation on NC machine tools and other devices that can be precisely centered. *For general centering, please use the spacer type. |

ECHT-FLEX NER Series

Model number NER□□W~

It has a unique center unit structure that is easy to install, and achieves a compact size with great transmission capacity.

- ・Large transmission force:

The new disc shape has resulted in a significant increase in torque compared to the previous series. - ・Outstanding ease of use:

The unique center unit structure that integrates the disk and spacer eliminates the need for troublesome disks at the site.

No assembly work is required. Installation and removal is simply a matter of removing and attaching the bolts between the center unit and the hub. - ・Compatible with large shaft hole diameters:

The center unit structure allows for a larger maximum shaft bore diameter than the previous series. - ・Non-backlash, no lubrication required, long life:

It has no backlash and high torsional rigidity, making it suitable for servo motor positioning devices.

Also, since there are no sliding parts, there is no need for lubrication. - ・Wide range of options available:

A wide range of combinations are possible, including shaft fastening with Power-Lock and flange mounting.

capacity

For medium to large capacity

Applicable shaft diameter

Φ25mm~Φ145mm

Torque Range

590~8500N・m

Long spacer

can be

Maximum: Hub face distance 6000mm

others

Compatible with CFRP long spacers

Electrical insulation specifications available

ECHT-FLEX NES Series

Model number NES□□W/S~

This is a small disc coupling that uses extra-super duralumin for the hub and spacer material.

- ・Low moment of inertia:

The hub is made of lightweight, high-strength extra-super duralumin, which, combined with the unique hub shape, achieves low inertia.

- ・High torsional rigidity:

The straight hub boasts high torsional rigidity and excellent tracking for servo motor drives, making it ideal for precise control. - ・Overwhelming product lineup:

A combination of low inertia hubs and straight hubs allows for 56 different product types and 3,252 different shaft hole diameter combinations. - ・Non-backlash:

Ideal for high-precision positioning operations. - ・High torque and reliable shaft fastening force:

The unique clamp shape increases the shaft fastening force. - Easy to install:

The hubs on both sides are centered using a special jig to ensure coaxiality during assembly.

The shaft is fastened using a clamping method, and can be installed by simply tightening the two clamp bolts on both sides.

capacity

For small capacity

Applicable shaft diameter

Φ4mm~Φ50mm

Torque Range

0.7~300N・m

Long spacer

None

Hub types and combinations

Straight hub x straight hub

Low inertia hub x low inertia hub

Straight hub x low inertia hub

ECHT-FLEX NEF Series

Model number NEF□□W/S~

We boast a wide lineup of general-purpose disc couplings, allowing you to choose the shaft fastening method that best suits your application.

Available for selection.

- ・Long life with no lubrication:

Since there are no sliding parts, it can be used for a long period of time without lubrication. - ・High torsional rigidity:

It combines high torsional rigidity with excellent flexibility. - ・Environment-resistant specifications also available:

Stainless steel and electroless nickel plating specifications are also available. - ・Shaft fastening method:

For details on features and usage, please refer to the details page.

Taper lock fastening, clamp fastening, key fastening, Power-Lock fastening - -Long spacer type also available:

Suitable for line shaft drive in combination with Miter Gear Box.

We also have a selection of long spacers in stock.

capacity

For medium capacity

Applicable shaft diameter

Φ9mm~Φ130mm

Torque Range

19.6~6860N・m

Long spacer

can be

Maximum: Hub face distance 6000mm

others

Compatible with CFRP long spacers

Electrical insulation specifications available

ECHT-FLEX NEH Series

Model number NEH□□W/U~

This is a large disc coupling that can be used with a maximum torque of 176,000 Nm.

- - A large, spacer-type coupling.

- In addition to the standard hub (N hub), there is also an adapter hub (A hub) that allows for a larger shaft hole diameter, and the disc connection part can be disassembled.

We offer a range of unit spacer hubs (U-hubs) that allow for easy removal and assembly of spacer units without the need for additional spacers. - - Gear coupling compatible specifications can also be manufactured for replacing gear couplings.

- -Long spacer types can also be manufactured.

- - Electrically insulated specifications can also be manufactured using split spacers and insulating bolt sets.

- If you require fastening other than with a key, please contact us.

capacity

For large capacity

Applicable shaft diameter

Φ72mm~Φ289mm

Torque Range

8820~176000N・m

Long spacer

can be

Maximum: Hub face distance 6000mm

others

Electrical insulation specifications available