Product Info Reducer

A reducer is a mechanical device that uses gears to reduce the rotational speed of the power obtained from the output shaft of a power source such as a motor and output it.

The ratio of the number of gear teeth on the input and output sides is the reduction ratio, and the output shaft can obtain torque that is inversely proportional to the reduction ratio.

We offer a lineup of three gear types: helical gears, hypoid gears, and worm gears. You can choose from the motor specifications, shaft arrangement (parallel shaft/ right-angle shaft), and output shaft shape (solid/hollow) that suit your purpose.

table of contents

Reducer related information

Types and Features of Gears

Our reducers use the following five types of gears. The features of each gear are as shown in the table below.

| Hypoid gear | Cylindrical Worm | Troidal Worm | Bevel gear | Helical gear | |

|---|---|---|---|---|---|

| gear |  |

|

|

|

|

| Axis Position | Right-angle shaft | Parallel shaft | |||

| Skew | Intersection | ||||

| efficiency | 80% | 40~70% | 40~80% | 90% | 90% |

| noise | Good | Excellent | Excellent | Fair | Fair |

| Gear meshing | Both sliding and rolling | Sliding | Sliding | Rolling | Rolling |

| Self-locking* | none | can be (Reduction ratio 1/60) |

can be (Reduction ratio 1/60) |

none | none |

*Self-lock: A function possessed by worm gears that prevents the input shaft from rotating from the output shaft.

Generally, it has a single reduction stage with a reduction ratio of 1/60.

Reducer product list

DCBL gear motor

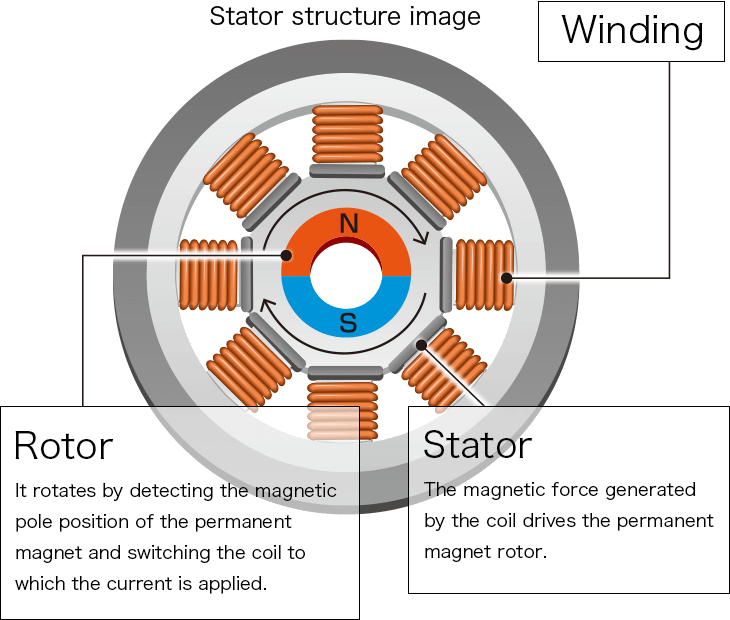

DCBL Hypoid Motor has a rotor that is a permanent magnet and a stator that is a coil, and does not require a commutator or brushes, so it does not require maintenance.

The rotor rotates by detecting the magnetic pole position of the rotor and switching the coil through which current flows.

Therefore, DCBL Hypoid Motor must be used in conjunction with a drive circuit (driver).

Tsubaki DCBL gear motors use permanent magnets and are more powerful and compact than conventional general-purpose motors.

We offer a lineup of DCBL Hypoid Motor motor capacities of 0.2kW, 0.4kW, and 0.75kW.

*The motor and driver must be used together.

DCBL Hypoid Motor

Model number DCHM~

This DCBL Hypoid Motor has a hypoid gear head and an orthogonal right-angle shaft for compactness.

Brake-equipped models are also available as standard models. Equipped with communication functions, it allows for various controls.

Although it is called DCBL Hypoid Motor, it is a motor that is powered by an AC power source.

*It is called DCBL Hypoid Motor because of its operating principle.

- - It has excellent speed control and is less susceptible to load fluctuations, achieving stable rotation speeds.

- - Permanent magnets are used in the rotor, resulting in low loss and high efficiency (equivalent to IE4).

- -Compared to induction motors, it is compact yet provides powerful output.

- - The speed control range is wide at 1:25, allowing operation from low to high speeds.

size

0.2kW~0.75kW

Reduction ratio

0.2kW:1/10~1/60

0.4kW:1/10~1/50

0.75kW:1/10~1/50

DCBL driver

DCBL driver is a dedicated driver that enables a wide range of operation for DCBL gear motors.

Unlike conventional induction motors, DCBL gear motors do not have a terminal box, and power is supplied and operation is controlled by connecting a cable to a DCBL driver.

*The motor and driver must be used together.

DCBL driver

Model number DCRD~

This is a DCBL gear motor driver exclusively for Tsubaki.

It is equipped with speed control, positioning operation, torque limit operation and various protection functions.

- - By constantly monitoring the gear motor's operating status with the driver, various controls can be easily achieved.

- - Supports multiple communication methods, making it easy to incorporate into existing equipment and remotely monitor operating status.

- - The motor and driver have overheat protection and overload protection functions, allowing for quick shutdown in the event of an abnormality.

- - The simple holding function can control the motor shaft so that it does not rotate when the motor is stopped.

Basic knowledge of DCBL Hypoid Motor

Internal structure

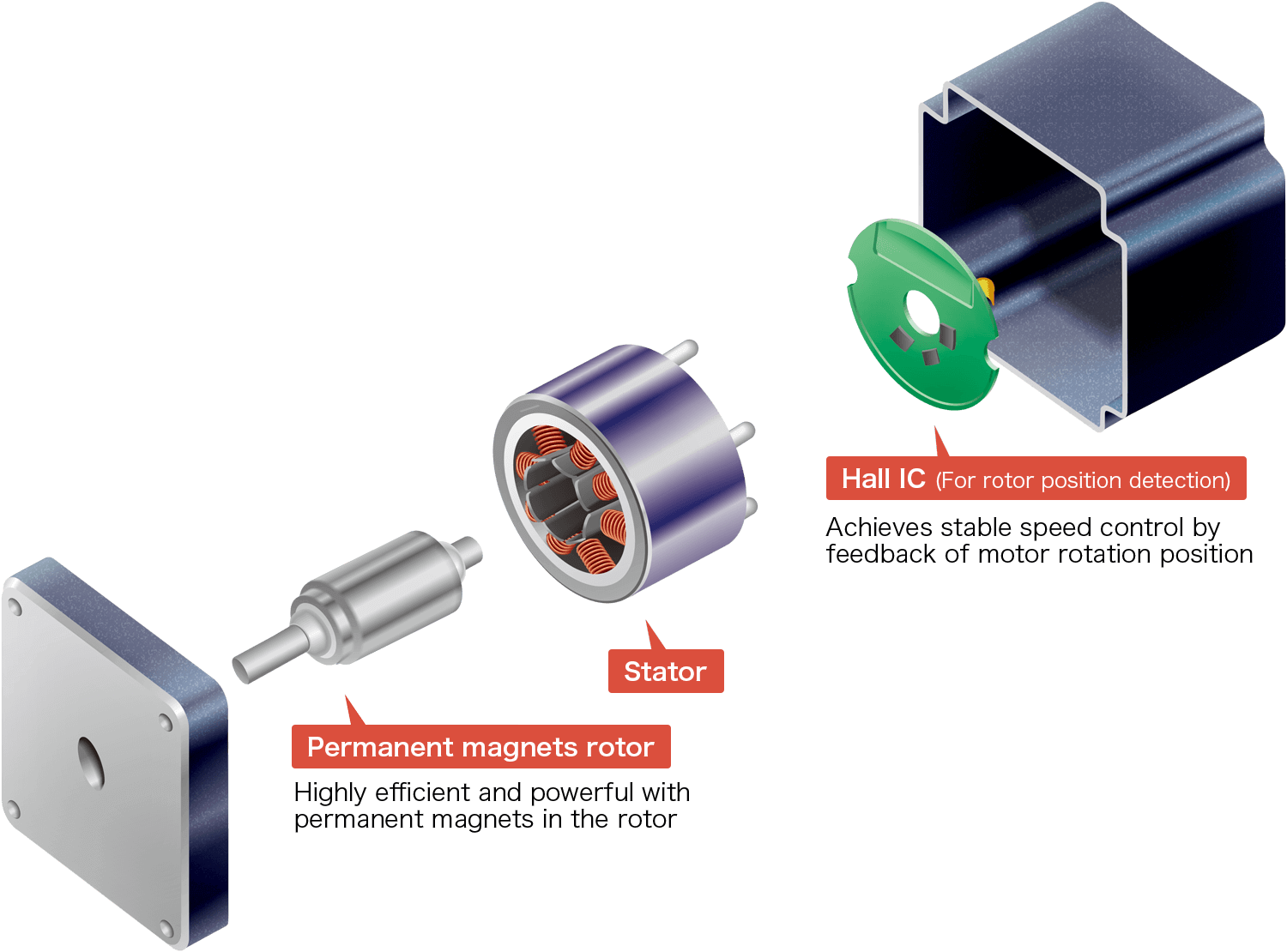

It consists of a rotor and stator made of permanent magnets, and a Hall IC for detecting the rotor position.

Stator structure: Difference from brushed motors

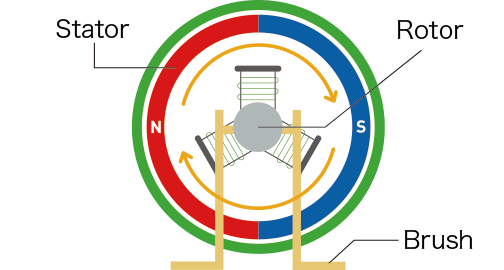

A typical brushed motor has parts called brushes inside the motor that come into contact with the commutator to switch the current and rotate the motor.

Repeated mechanical contact causes wear on the brushes, requiring regular maintenance.

On the other hand, DCBL Hypoid Motor have a rotor that is a permanent magnet and a stator that is a coil, and there are no mechanical contacts. This means that there is no wear on parts like in brushed motors, and you can expect a long lifespan.

Rotor position detection mechanism structure: Difference from servo motors

Both DCBL Hypoid Motor and servo motors constantly provide feedback of the rotor's rotational position to the driver, achieving stable speed control even when the load fluctuates.

Servo motors use a high-precision encoder to detect the rotor position, so they have excellent speed accuracy, torque accuracy, and stopping accuracy, but they are expensive.

DCBL Hypoid Motor extracts only the speed control function from a servo motor by using a Hall IC instead of an expensive encoder.

It can achieve high-precision speed control close to that of a servo motor at low cost.