DCBL Hypoid Motor

Meeting the needs for automation and energy conservation

Tsubaki's next-generation motors: a new standard for motor selection

"DCBL Hypoid Motor" are motors that enable speed control like servo motors and offer excellent cost performance. They are also energy-efficient, environmentally friendly, and compact. Combined with Tsubaki's hypoid gear, it maximizes the tenacious torque inherent in a motor that does not step out.

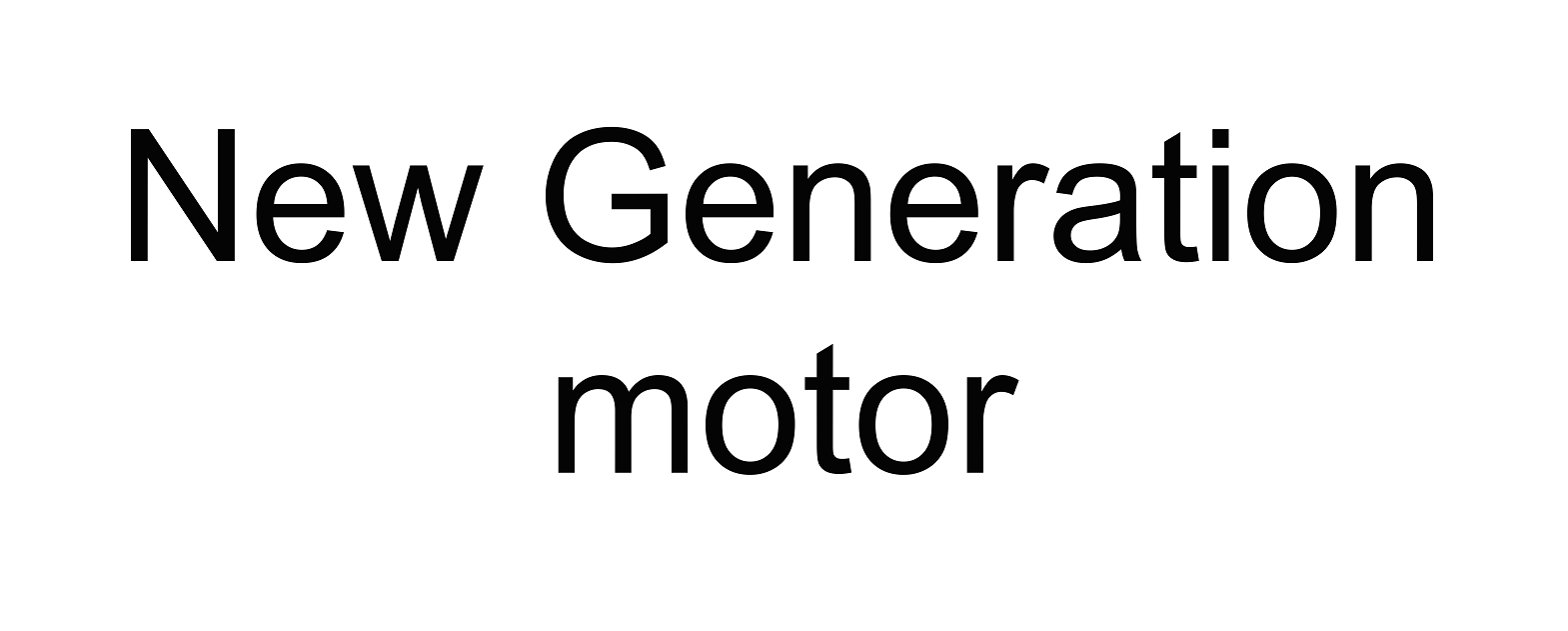

High efficiency with the power of permanent magnets

For speed control, choose Tsubaki's DCBL Hypoid Motor!

"DCBL Hypoid Motor" is a compact and highly efficient motor that uses permanent magnets in the rotor.

The motor is driven by receiving power supply and rotation commands from a dedicated driver, and the motor's rotation speed is detected by a sensor and feedback controlled, providing excellent speed control.

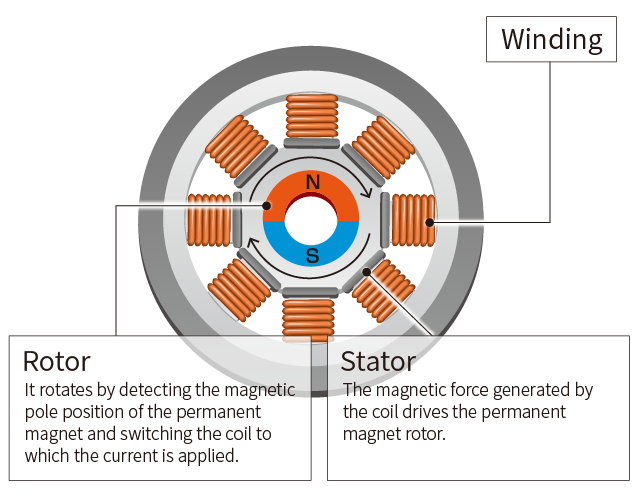

DCBL Hypoid Motor structure

In the past, inverter drives or servo motors were the mainstream for speed control, but in recent years, DCBL Hypoid Motor have been attracting attention as a new option.

- Although the speed is controlled using an inverter, the speed range is narrow and torque is insufficient.

- To save energy, we want to use a highly efficient motor, but servo motors are too expensive...

- Although a servo motor is used, only speed control is used.

... DCBL Hypoid Motor is the motor that meets these and other demands.

Comparison with inverter drive and servo motor

Excellent speed control

vs. inverter drive

The built-in Hall IC detects the motor's rotation speed and provides feedback to the driver, ensuring a stable rotation speed even when the load fluctuates!

Wide variable speed range

vs. inverter drive

Motor Speed Range

100~2500 r/min

compact

vs. inverter drivevs. servo motor

When attaching a reducer to a servo motor, flange mounting is required, which increases the overall length. However, because DCBL Hypoid Motor are built-in, they are extremely compact, contributing to space savings in equipment.

High efficiency means less loss, making it possible to downsize the motor and eliminate the need for a cooling fan, resulting in a more compact design.

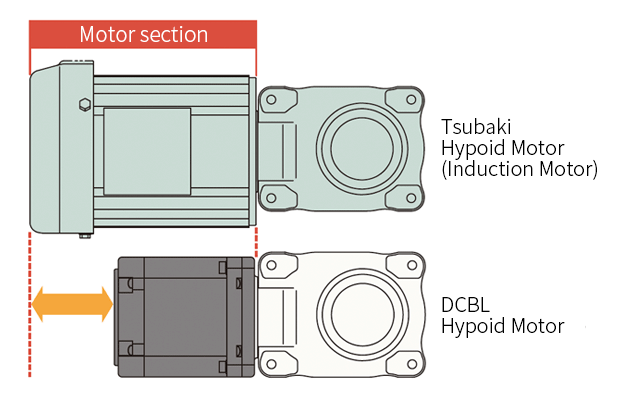

Compared to induction motors

Motor overall length reduced by 38 %

(Example) At 0.2kW, it will be 67.2mm shorter.

Furthermore, as a unique feature of Tsubaki

A temperature sensor is installed inside the motor to prevent burnout

A temperature sensor is built into the motor to constantly monitor the winding temperature, protecting the motor from burnout. This allows for safe use even in applications where the motor is started frequently.

Dedicated driver for controlling motors as desired

Tsubaki has developed a dedicated driver to achieve a wide range of movements, allowing anyone to easily control the movements.

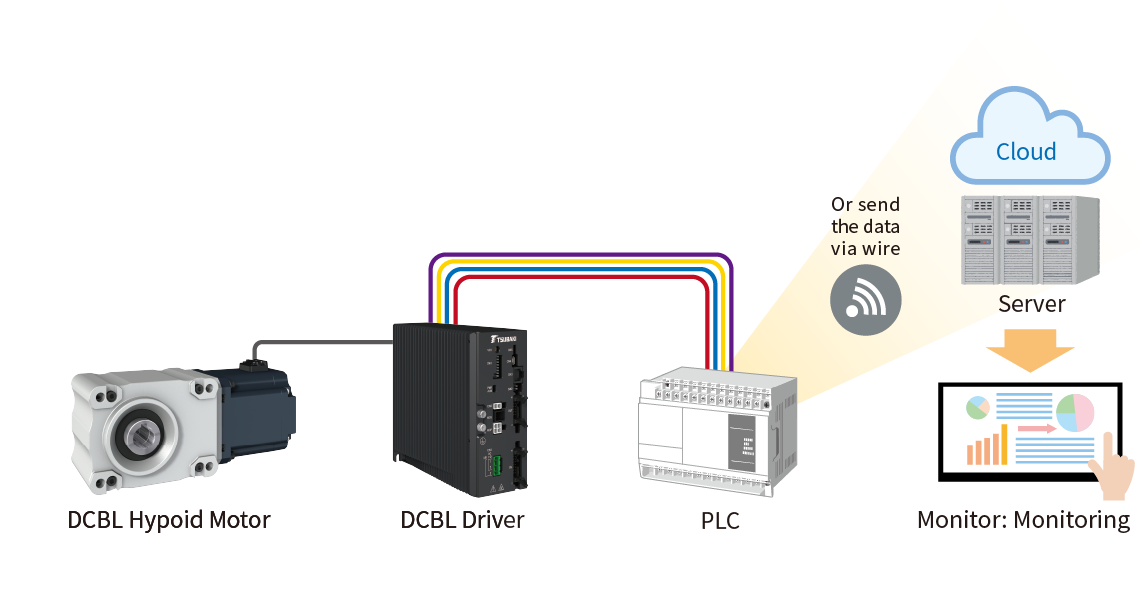

Since it monitors the motor status, it can switch to the optimum rotation speed depending on the load situation, automatically operate to a predetermined position, etc. Furthermore, since it is equipped with communication functions, remote monitoring is easy.

Communication functions enable predictive maintenance and remote monitoring

It is equipped with a communication function and can quickly detect motor overheating, overload, etc. and stop the motor.

Connect to PLC

The driving status is constantly monitored, allowing speed control according to the situation, and data is remotely monitored and uploaded.

(Requires optional communication cable)

The communication specification uses the versatile Modbus-RTU, and in addition to RS-485, it also has a micro USB terminal that allows easy connection to a PC.

By connecting to a PC, you can set parameters and update the dedicated driver.

Using the dedicated PC software, you can easily change the settings of each parameter. New functions will be added in the future through updates to the driver program.

Software update notice

2024.03.01 Errors corrected.

(Ver2.0.1)

2023.10.02 ・Trial run function added * / Function not to write to memory added *.

- Real-time monitor changed/IO monitor added *.

- Added error code display.

・Parameter description added.

-Improved operational stability.

(Ver2.0.0)

*Can be used with drivers shipped after October 1, 2023.

2023.04.26 Improved operational stability.

(Ver1.0.14.0)

2023.03.27 Changes have been made to the number of program operation points, program operation conditions have been added, and operational stability has been improved.

(Ver1.0.13.0)

We recommend using the updated version as it has improved the stability of the software.

Compatible drivers will be available for shipments from April 2023 onwards.

* Previously shipped drivers can also be used with updated versions.

However, some added functions cannot be used. Please refer to Instruction Manuals for details.

DCBL Hypoid Motor allow you to select the optimum operation mode depending on the application.

JOG operation

This is an operation in which the motor starts moving when the forward or reverse signal is turned ON.

horizontal conveyor

Even when multiple workpieces of different masses are fed, the speed remains stable and a wide range of variable speeds is possible, from low to high.

Reasons for Selection

- Stable speed control is possible

- Tenacious torque output

- Quickly detect abnormal occurrences

Positioning operation

It determines the stopping position at the set rotation amount and stops accurately.

packaging machine

The wrapping and content labels are attached inside the device, and the process of sending out is controlled at high speed.

Reasons for Selection

- Achieves high-speed, high-frequency operation

- Can be operated at a constant speed

- Easy acceleration/deceleration control

Program operation

This function automatically operates according to the parameters set in advance.

Mixer

To mix materials uniformly, the motor must operate at a constant speed even when the viscosity changes. DCBL Hypoid Motor are ideal because of their excellent speed control.

Reasons for Selection

- Stable speed control is possible

- Tenacious torque output

- Easy switching of operation mode according to agitated materials

Torque limited operation

This is an operation that monitors the output shaft torque and prevents it from exceeding a certain torque.

Screw tightening machine

Setting a torque limit (motor load rate) prevents damage caused by overtightening.

Reasons for Selection

- Load factor can be monitored using communication functions

- The motor is compact

- Long life due to no sliding parts

Lineup

Series

- DCBL Hypoid Motor

Supported capacity

0.2, 0.4, 0.75kW

Reduction ratio

1/10~1/60

Brake-equipped models are also available.