Product Info Reducer

A reducer is a mechanical device that uses gears to reduce the rotational speed of the power obtained from the output shaft of a power source such as a motor and output it.

The ratio of the number of gear teeth on the input and output sides is the reduction ratio, and the output shaft can obtain torque that is inversely proportional to the reduction ratio.

We offer a lineup of three gear types: helical gears, hypoid gears, and worm gears. You can choose from the motor specifications, shaft arrangement (parallel shaft/ right-angle shaft), and output shaft shape (solid/hollow) that suit your purpose.

Table of contents

Reducer related information

Types and Features of Gears

Our reducers use the following five types of gears. The features of each gear are as shown in the table below.

| Hypoid gear | Cylindrical Worm | Troidal Worm | Bevel gear | Helical gear | |

|---|---|---|---|---|---|

| gear |  |

|

|

|

|

| Axis Position | Right-angle shaft | Parallel shaft | |||

| Skew | Intersection | ||||

| efficiency | 80% | 40~70% | 40~80% | 90% | 90% |

| noise | Good | Excellent | Excellent | Fair | Fair |

| Gear meshing | Both sliding and rolling | Sliding | Sliding | Rolling | Rolling |

| Self-locking* | None | can be (Reduction ratio 1/60) |

can be (Reduction ratio 1/60) |

None | None |

*Self-lock: A function possessed by worm gears that prevents the input shaft from rotating from the output shaft.

Generally, it has a single reduction stage with a reduction ratio of 1/60.

Reducer product list

Miter Bevel Gearbox

A miter bevel gearbox that changes the direction of force transmission by 90°, or changes it by 90° and distributes it left and right (up and down).

Tsubaki's miter bevel gearboxes come in a full lineup, from small to large models.

This is a long-lasting product that has been used for a variety of purposes for over half a century since its release.

High-precision spiral bevel gears that comply with AGMA standards are used to achieve high transmission and efficiency.

To meet various market needs, we also support various special specifications (speed ratio 1:1 to 1:3).

Miter Gear Box

Model number ED~

High performance, high efficiency general-purpose spiral bevel gearbox with right-angle shaft.

- ・With our extensive track record and experience, we have earned a high reputation for reliability from customers in a wide range of fields.

- ・A full lineup from small to large models. Choose the best one from a wide range of models.

We also handle various special specifications to meet all market needs. - -High-precision spiral bevel gears conforming to AGMA standards are used, resulting in high efficiency and high transmission capacity.

It has been realized. - - compatible with Food-grade lubricants: models filled with NSF-certified H1-grade Food-grade lubricants are also available.

ideal for FS SC22000 certification. the external Dimensions are the same AS the standard specifications.

Input capacitance

0.014~335kW

Reduction ratio

1/1, 1/1.5~1/3

ARA Gear Box

Model number ARA~

A compact and ultra-lightweight spiral bevel gearbox.

- -Small, lightweight, and beautiful: The case is made of aluminum die-cast (ADC).

- -High corrosion resistance: the shaft material is made of stainless steel (SUS304), which has excellent corrosion resistance.

- - Universal mounting: Can be mounted in any direction and is easy to install.

- High efficiency, high transmission capacity, low noise and low vibration: High precision spiral bevel gears are used, allowing for a wide range of

High functionality is achieved. - - compatible with Food-grade lubricants: models filled with NSF-certified H1-grade Food-grade lubricants are also available.

ideal for FS SC22000 certification. the external Dimensions are the same AS the standard specifications.

Input capacitance

0.005~3.15kW

Reduction ratio

1/1, 1/2

Basic knowledge of miter bevel gearboxes

A miter bevel gearbox is a mechanical element that changes the direction and distributes torque obtained from a single power source, enabling flexible layout and easy synchronized operation of multiple mechanisms.

The basic functions are...

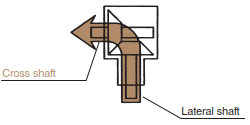

1. Change the direction of force transmission by 90°.

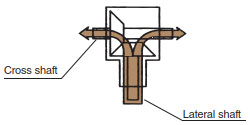

2. Change the direction of force transmission by 90° and distribute it left and right (up and down).

Examples of applications include:

3. Line up Miter Gear Box and connect the cross shaft to form the input.

Rotate the lateral axis.

4. Use a lateral 2-axis type and input from the cross axis.

Rotate the opposing lateral axis in the opposite direction.