Product Info Reducer

A reducer is a mechanical device that uses gears to reduce the rotational speed of the power obtained from the output shaft of a power source such as a motor and output it.

The ratio of the number of gear teeth on the input and output sides is the reduction ratio, and the output shaft can obtain torque that is inversely proportional to the reduction ratio.

We offer a lineup of three gear types: helical gears, hypoid gears, and worm gears. You can choose from the motor specifications, shaft arrangement (parallel shaft/ right-angle shaft), and output shaft shape (solid/hollow) that suit your purpose.

Table of contents

Reducer related information

Types and Features of Gears

Our reducers use the following five types of gears. The features of each gear are as shown in the table below.

| Hypoid gear | Cylindrical Worm | Troidal Worm | Bevel gear | Helical gear | |

|---|---|---|---|---|---|

| gear |  |

|

|

|

|

| Axis Position | Right-angle shaft | Parallel shaft | |||

| Skew | Intersection | ||||

| efficiency | 80% | 40~70% | 40~80% | 90% | 90% |

| noise | Good | Excellent | Excellent | Fair | Fair |

| Gear meshing | Both sliding and rolling | Sliding | Sliding | Rolling | Rolling |

| Self-locking* | None | can be (Reduction ratio 1/60) |

can be (Reduction ratio 1/60) |

None | None |

*Self-lock: A function possessed by worm gears that prevents the input shaft from rotating from the output shaft.

Generally, it has a single reduction stage with a reduction ratio of 1/60.

Reducer product list

Worm reducer (Worm Power Drive, Troi Drive)

A worm reducer is a reducer (gearbox) that uses worm gears. Unlike other gear transmissions, it uses sliding contact, which means that vibration and noise are extremely low, and a pair of worm gears can achieve a large reduction ratio (generally 1/10 to 1/60).

This gear also has a self-locking effect to prevent reverse rotation.

Click here for the basics of worm reducers

Tsubaki's worm reducers use two types of worm gears: Troidal shaped and cylindrical.

The toroidal worm has high transmission capacity and allows for compact equipment, while the cylindrical worm optimizes capacity, efficiency, and cost.

With a wide variety of options, it can be used for a variety of purposes.

Troi Drive TD Series

Model number TD~

High transmission capacity and high efficiency with the adoption of Troidal worm gear worm.

- ・ Troidal Worm transmits power over the entire surface, providing high transmission capacity and functionality, while being a compact device.

High performance worm reducer ideal for your design. - - In particular, by pursuing a unique gear meshing theory, we have achieved extremely low rotational fluctuation.

- The lineup includes eight sizes with a center distance of 125 to 315, and reduction ratios of 1/10 to 1/60 and 1/100 to 1/3600.

- - Two types are available: a solid output shaft type with a foot mount case, and a hollow output shaft type

with a flange mount case. - -We promise ultimate compactness and lightweight design for all layouts.

Size

Between shafts 125~315mm

Reduction ratio

1/10~1/3600

torque

2700~47000N・m

Worm Power Drive EW, EWM(R), EWJ, EWJM(R) Series

Model number EW(J)・EW(J)M(R)~

High precision and compact. Based on Foot mount, it has a well-balanced design between cost and ease of maintenance.

A wide variety of options make it possible to make equipment more compact.

- - Achieves increased capacity, efficiency, and cost effectiveness without compromising accuracy and small footprint.

- -Based on Foot mount, both solid and hollow output shaft types are available.

- -Available in small to medium sizes (center distance 25 to 200).

- ・MR series is compatible with High Efficiency motors. (IE3 Class : Premium Efficiency )

Size

Between shafts 25-200mm

Reduction ratio

1/10~1/3600

torque

12~5300N・m

Worm Power Drive SW, SWM(R), SWJ, SWJM(R) Series

Model number SW(J)・SW(J)M(R)~

A dedicated case based on shaft and flange mounting is used, contributing to the simplification of the device.

- - Achieves increased capacity, efficiency, and cost effectiveness without compromising accuracy and small footprint.

- - Both solid and hollow output shafts are available.

- ・ Power-Lock tapered bush shafts are also available, contributing to reduced assembly time.

- -Available in small to medium sizes (center distance 25 to 200).

- ・MR series is compatible with High Efficiency motors. (IE3 Class : Premium Efficiency )

Size

Between shafts 25-200mm

Reduction ratio

1/10~1/3600

torque

12~5300N・m

TERUS

Model number EWGM/SWGM/TDGM~

This is a worm gear motor that combines a worm reducer with a gear motor.

- - Excellent worm characteristics: High strength, quietness, self-locking, etc., suitable for a variety of uses and purposes.

- - Compact equipment: Costs can be reduced by reducing the number of parts.

- - Wide range of options: Supports various motor brake options, including international standard motors and brakes

with one-touch manual release. - *This product is made to order. Please contact us if you are considering purchasing.

Motor Capacity

Three phase 0.1~2.2kW

Reduction ratio

1/100~1/3600

torque

39~11143N・m

Coverage by series

Size

| 25 | 35 | 42 | 50 | 63 | 70 | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 280 | 315 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EW(J)・SW(J) | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| TD | ● | ● | ● | ● | ● | ● | ● | ● |

Reduction ratio

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

|---|---|---|---|---|---|---|---|---|

| EW(J)・SW(J) | ● | ● | ● | ● | ● | ● | ● | ● |

| TD | ● | ● | ● | ● | ● | ● |

| 100 | 150 | 200 | 250 | 300 | 400 | 450 | 500 | 600 | 750 | 800 | 900 | 1000 | 1200 | 1500 | 1800 | 2400 | 3000 | 3600 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EW(J)・SW(J) | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| TD | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

Output Torque

Please check Major Specifications kW ratings table of each product.

Basic knowledge of worm reducers

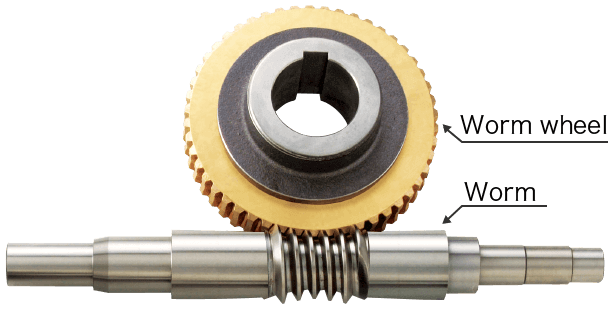

A worm reducer has a worm connected to the input shaft and a worm wheel connected to the output shaft that mesh together.

It rotates.

If the worm has one tooth, the worm wheel advances one tooth for each rotation of the worm. If the worm has one tooth and the worm wheel has 100 teeth, the reduction ratio is 1/100.

Internal structure of a worm reducer

The features of the worm reducer are as follows:

- High reduction ratio

A pair of worm gears can provide a large reduction ratio (typically 1/10 to 1/60). - -Low noise

Unlike other gear transmissions, sliding contact is used, resulting in extremely low vibration and noise. - -Self-locking to prevent rotation from the output shaft to the input shaft

Generally, the self-locking effect can be expected when the reduction ratio is between 1/50 and 1/60.- *Tsubaki worm reducers are limited to 1/60 as they place emphasis on efficiency.

- * Self-locking properties may be reduced due to shocks or vibrations.

Self-locking cannot be guaranteed, so if reliable stopping or holding is required, be sure to provide a separate holding device.

- -Little rotation unevenness

Generally, there is less rotational fluctuation than with other reduction mechanisms, making it suitable for situations where rotational fluctuation can affect product quality, such as semiconductor manufacturing.