Automatic roller chain lubricator

- The lubricant filled in the Tsubaki roller chain automatic oiler complies with FDA (U.S. Food and Drug Administration) Federal Regulations 21 CFR 178.3570 and has been certified H1 by the NSF (U.S. National Public Health Foundation), ensuring its safety.

- It can be used in general manufacturing processes as well as food manufacturing processes.

| ※ | CAD data will be provided via a link to CADENAS Web2CAD Co., Ltd.'s CAD Drawing Library site "PARTcommunity." |

| ※ | For inquiries about CAD data and PARTcommunity, please contact Cadenas Web2CAD. Cadenas Web to CAD Co., Ltd. TEL: (03)5961‐5031 FAX: (03)5961‐5032 |

Catalogs and Instruction Manuals

Features

-

-High safety and reliability

The lubricating oil filled in the dispenser body meets FDA federal regulations and has been certified H1 by NSF, so it can be used safely in food manufacturing processes.

We contribute to "improving safety" in our customers' product liability countermeasures and HACCP systems.

-

・Compatible with explosion-proof applications

This product has passed the inspection by DEKRA, the type inspection agency designated by the Ministry of Health, Labor and Welfare, and is certified as an explosion-proof electrical equipment product.

Safety has been proven in hazardous locations where explosive gas and vapor atmospheres may be generated, as there is no risk of explosion or fire due to sparks or high temperatures generated by electrical equipment.

-

・Freely set the usage period

The usage period can be easily set between 1 and 12 months using a flat-head screwdriver. After the period is set, the gas generator will automatically perform lubrication.

-

- Reduction of maintenance man-hours

Automatic lubrication eliminates the need for frequent manual lubrication, simplifying lubrication planning.

The lubricator body also has an inspection window, allowing you to check the amount used and the operating status at any time through the transparent PET container.

-

·compact

It is small in size, with a diameter of Φ50 and a height of 104 mm (contents: 125 mL).

-

- Free installation direction

The orientation of the lubricator body can be freely arranged, such as facing downward, upward, or sideways.

Note: When using the brush, point it downwards only.

-

・Dustproof/waterproof type

Certified to the dustproof and waterproof standard IP68, it can be used in environments where it is exposed to water or dust.

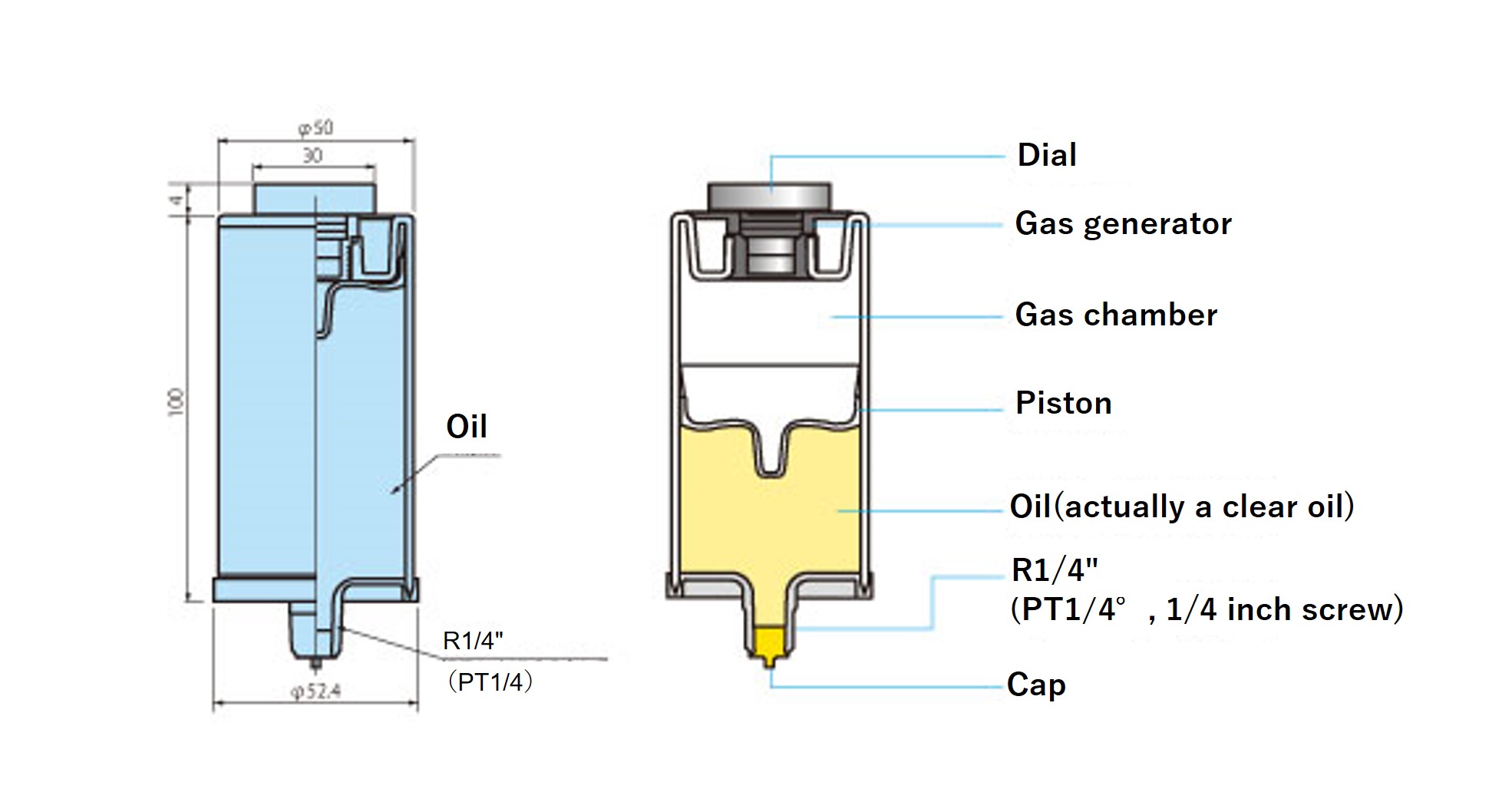

Structure and operating principle

When the gas generator is turned on, H2 gas is generated, and the gas pressure pushes the piston, discharging the lubricating oil from the bottom of the container.

At this time, the amount of H2 gas generated is controlled by the dial setting, and the amount of lubricant discharged is continuously adjusted between 1 and 12 months.

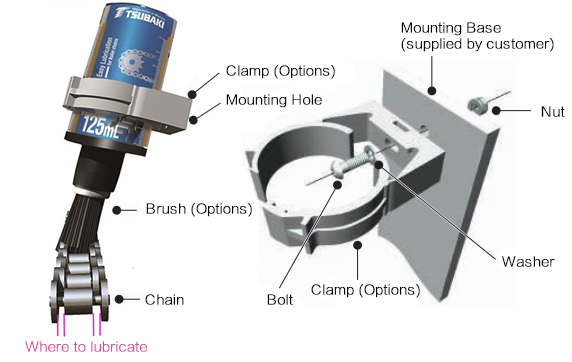

Installation Method

Use the optional brush to get lubricant into the gap between the outer and inner plates on the slack side of the chain.

Install the brush so that it lightly touches the chain plate (see diagram below).

If you are using the optional clamp, either drill a tapped hole in the bar or similar and fasten it with an M4 bolt, or drill a through hole for the M4 bolt and fasten it with a bolt and nut (see the diagram below).

[Recommended range of use]

- ・Chain size

For Drive chain: #40 to #100 (example)

For Small size conveyor chain: #40 to #100, #2040 to #2100

- Chain speed

50m/min以下

- - Current lubrication method

Brush application, drip lubrication

Note: Do not use in an oil bath or forced lubrication area as this will result in poor lubrication.

*Customers must provide their own bolts, nuts (M4), and washers.

application

・Drive applications

・Transportation applications

・For hanging applications

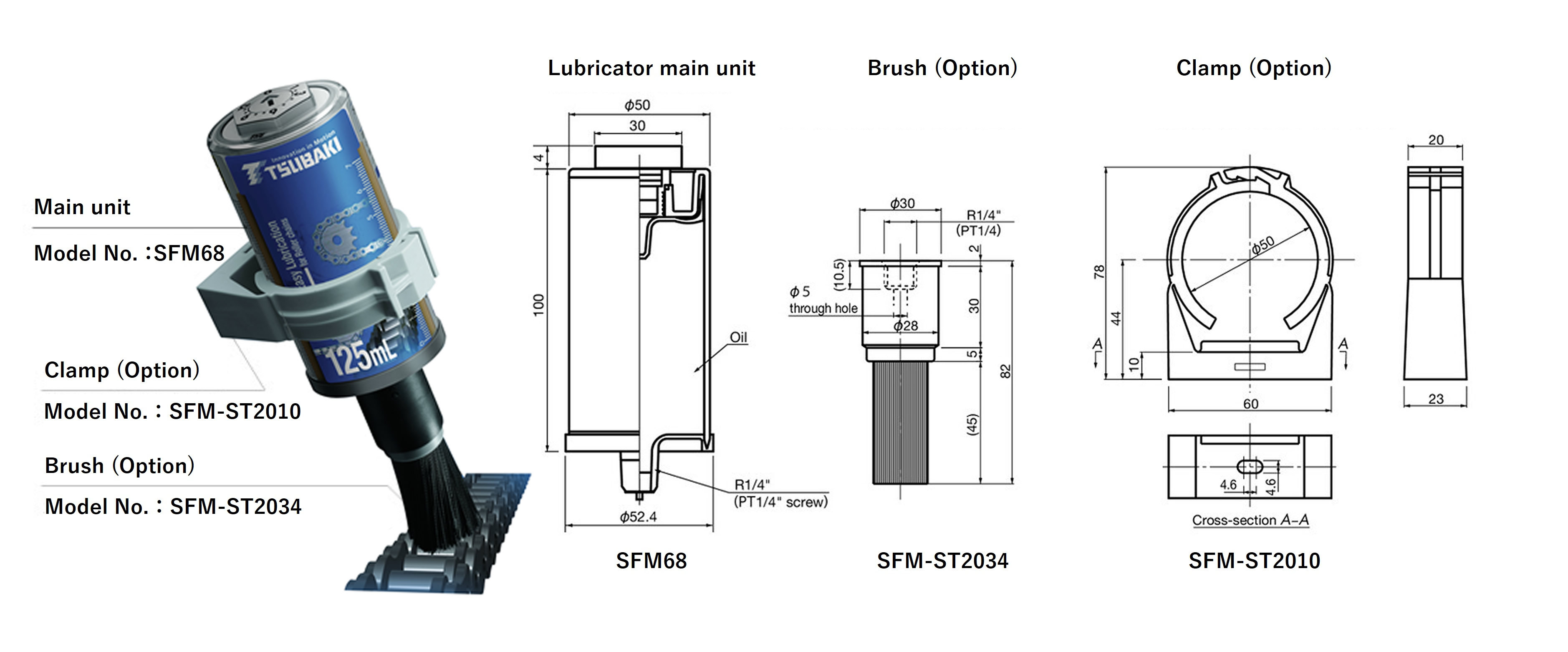

Model number, specifications, and dimensions

Main unit model number: SFM68

Brush model number: SFM-ST2034

Clamp model number: SFM-ST2010

| How it works | H2 gas pressure (battery operated) |

|---|---|

| Operating pressure | Maximum 0.5MPa |

| Contents | 125ml |

| Discharge volume period setting range | Infinitely variable from 1 to 12 months (20°C atmosphere) |

| Operating temperature range | ‐20℃~55℃ |

| lubricating oil | Food grade machine oil (H1) |

Note: This product is designed for use in Japan. Therefore, we may not be able to provide the necessary documentation for export to the appropriate country or export conditions.

| Model number | DXF Data 3D CAD Data |

Standard price | Delivery |

|---|---|---|---|

| SFM68 | DXF・3DCAD | お問合せください | お問合せください |

| SFM-ST2034 | DXF・3DCAD | お問合せください | お問合せください |

| SFM-ST2010 | DXF・3DCAD | お問合せください | お問合せください |