Q&A High-speed lifter

We have posted frequently asked questions from customers in Q&A format. Please click on the question to proceed to the answer.

Lift Master

Words in Q&Aof

technology

Support/Specifications

Usage environment

others

| Q32 | How do I request a certificate of non-applicability? |

|---|

| Q1 | How do you control intermediate stops? |

|---|---|

| A1 | We recommend using a servo motor for control. For three-phase motor specifications, use the optional rotary encoder [option symbol: E]. Back to Questions |

| Q2 | What is the repeatability of the lifter's positioning accuracy? |

| A2 | For a constant load, the repeatability is ±1mm. Back to Questions |

| Q3 | Is it possible to set multiple lifter stop positions? |

| A3 | By installing a servo motor or a three-phase motor with a rotary encoder [option symbol: E], it becomes possible to control stopping at multiple points. Back to Questions |

| Q4 | I would like to operate multiple Lift Master, what is the procedure? |

| A4 | There are the following methods for operating multiple units.   |

| Q5 | Can a cantilever lifter perform a downward pressing operation? |

| A5 | In principle, pressing operations are not possible. |

| Q6 | Cantilever lifters are freestanding, but do they need support at the top end? |

| A6 | In principle, no support is required for standard models. However, support may be required depending on the operating conditions (acceleration/deceleration, OHL, etc.). Back to Questions |

| Q7 | How long can Lift Master stroke be made? |

| A7 | The standard stroke limit is 1500mm, but we can manufacture with your desired stroke up to 2000mm after confirming the lifting load and OHL conditions. |

| Q8 | Can it be installed in any direction? |

| A8 | The standard specification is floor installation only. |

| Q9 | I want to drive at high speeds. What is the maximum speed of Lift Master? |

| A9 | For standard specifications/U speed, the maximum speed is 150mm/s with a three-phase motor and 166mm/s with a servo motor.  |

| Q10 | What are some ways to lower the floor? |

| A10 | To make it easier to bring the lower limit of the arm closer to the floor, the motor can also be installed at the top.  |

| Q11 | I would like to operate Lift Master frequently, but what are the operating frequency limits? |

| A11 | The allowable Percentage duty cycle * of the standard Ball screw type is 30%ED. |

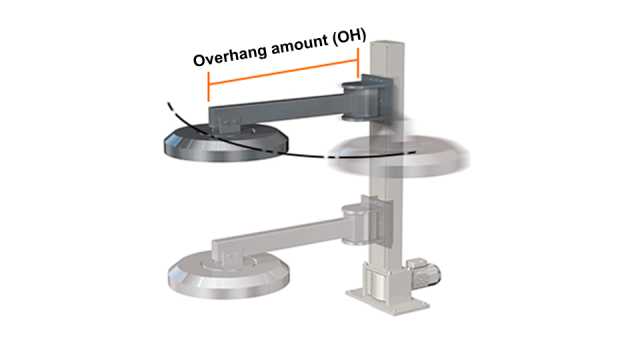

| Q12 | What is the allowable OHL when the center of gravity is not directly in front of Lift Master? Can it be handled if the center of gravity is located away from the OHL load curve? |

| A12 | If the center of gravity is within the arc of the overhang, the allowable OHL can be determined from the OHL load curve.   |

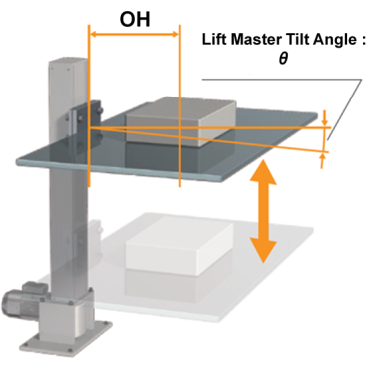

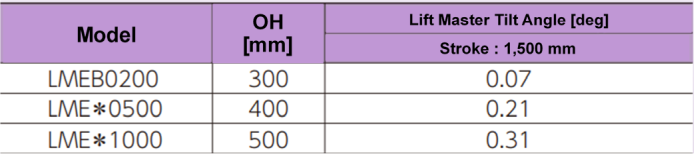

| Q13 | How much does Lift Master tip over when carrying the rated load? |

| A13 | The table below shows the reference values for the amount of tilt at the upper stroke limit and allowable OHL.   |

| Q14 | What is the expected lifespan of Lift Master? |

| A14 | The expected lifespan of Lift Master is determined by the expected running life of the screws. Trapezoidal Screw type (LMEM) The expected life span is determined when the total travel distance reaches 5km, regardless of the lifting load (reference value).Ball screw type (LMEB) The lifespan of Ball screw is determined by flaking caused by fatigue on the rolling surface. Please check the approximate lifespan in the graph below.However, if there is a lot of impact or if proper lubrication and maintenance are not performed, the expected travel distance will be significantly reduced. Expected travel distance (km) = Actual load stroke (m) × frequency of use (times/day) × number of operating days/year × 10-3 × expected years The expected lifespan varies depending on the lifting load.If the load fluctuates significantly during the stroke, calculate the equivalent load using the following formula. PM = PMIN + 2 × PMAX3 P M: Equivalent load N P MIN: Minimum load N P MAX: Maximum load N ・This graph shows travel distance based on the L10 life of Ball screw (the life that 90% or more of the total will reach).- If there are many impacts or if proper lubrication and maintenance are not performed, the expected travel distance will be significantly reduced. ・If a longer life is required, we will consider changing Ball screw to suit the load conditions.  |

| Q15 | What is the coasting distance and stopping accuracy of Lift Master? |

| A15 | The coasting distance and stopping accuracy when descending are as follows: LMEB0200H: Coasting distance: approx. 1.5 mm / Stopping accuracy: approx. ±0.5 mm |

| Q16 | Is DC motor drive (battery power) supported? |

| A16 | It may be possible depending on the conditions of use. |

| Q17 | Can you handle special lifter sizes, strokes, etc.? |

| A17 | Special support is available depending on the conditions of use. |

| Q18 | Are high rigidity specifications available? |

| A18 | Special support is available depending on the conditions of use. |

| Q19 | Is it possible to drive Lift Master with a servo motor? |

| A19 | Ball screw type LMEB comes standard with a servo motor. Back to Questions |

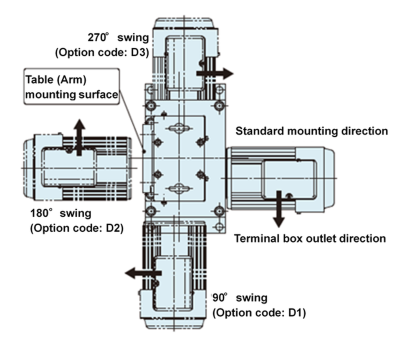

| Q20 | Can the motor mounting position and direction be changed? |

| A20 | The motor mounting direction can be changed as an option. [Option code: D1 to D3]  |

| Q21 | Can I add more position detection sensors to a cantilever lifter? |

| A21 | As an option, position detection sensors (option symbols: [L1 to L3]) are available. |

| Q22 | Can stainless steel specifications be manufactured? |

| A22 | It is possible to change some parts (other than strength components) such as the cover to stainless steel. Back to Questions |

| Q23 | Is it possible to use special grease (food-grade, low-dust type)? |

| A23 | Yes, we can. Please fill in the "High-speed lifter Selection Request Form" or the technical sheet at the end of the catalog with your usage conditions and contact us. Back to Questions |

| Q24 | Can the motor voltage be doubled? |

| A24 | As an option, a 400V motor voltage (option symbol: V) is available. Back to Questions |

| Q25 | Can bellows be retrofitted? |

| A25 | It cannot be retrofitted. When considering the product, please also consider whether or not you need bellows. Back to Questions |

| Q26 | Can you manufacture arms? |

| A26 | Special requests are possible. Please fill in the "High-speed lifter Selection Request Form" or the technical sheet at the end of the catalog with your usage conditions and contact us. Back to Questions |

| Q27 | Are heat-resistant specifications available? If so, what is the maximum heat resistance temperature? |

| A27 | This will vary depending on the conditions of use (temperature, operating frequency, load), so please contact us for details. Back to Questions |

| Q28 | I would like to use it in a very clean environment. Can this be accommodated? |

| A28 | Because Lift Master has an open structure, cleanliness cannot be guaranteed, but we can take measures to reduce dust generation from each part. Raydent treatment (ball screw guide) |

| Q29 | Can it be used outdoors? Can it be exposed to water? |

| A29 | Lift Master is designed for indoor use and is not intended for use in locations where it may come into contact with water.  |

| Q30 | Is cold resistant series available? |

| A30 | Special support is available depending on the conditions of use. |

| Q31 | Are there any heat-resistant bellows? |

| A31 | Heat-resistant specifications are not available. |

| Q32 | How do I request a certificate of non-applicability? |

| A32 | Please request a non-applicable certificate through your point of purchase. Back to Questions |