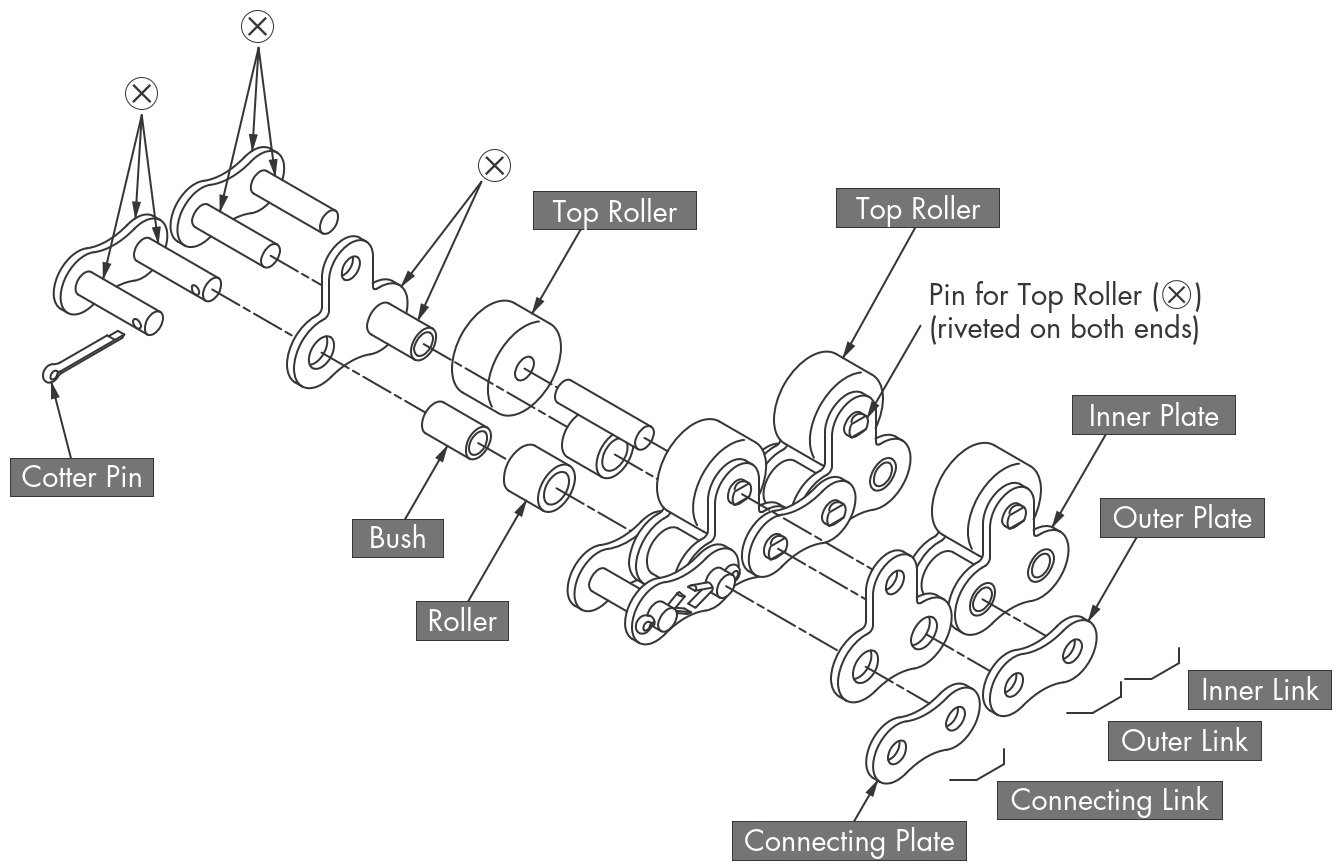

RS type chain with top rollers

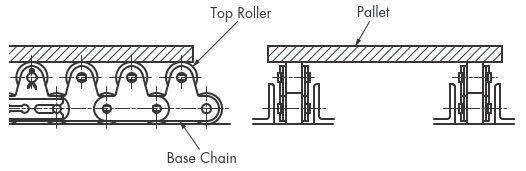

- A free flow chain using an RS Chain base with a raised link plate with freely rotating top rollers attached.

- The width of the chain itself is smaller than other free flow chains, and the top roller is supported by plates on both sides, making it a sturdy free flow chain.

Suitable for conveyors. - Standard Series, lambda (Lube-free) specifications, and SS (stainless steel) specifications are available.

- * NP Series (nickel plating) are also available, so please contact us for details.

Purpose

- It is suitable for transporting heavy objects at low speeds, and is widely used in automobile production facilities in particular.

Catalogs and Instruction Manuals

About each specification

Standard Series

- - All parts of the chain body, including the rollers, are heat-treated and hardened steel.

- -You can choose between Plastic Roller and steel rollers for the top rollers.

- ・使用温度範囲:-10℃~150℃

- ・Lubricating is required.

Lambda (Lube-free) specification

- - The use of special oil-impregnated bush allows for long-term use Lube-free. (Oiling is required for steel top rollers.)

- -You can choose between Plastic Roller and steel rollers for the top rollers.

- -allowable tension is the same as Standard Series, but the inner and outer plates are black oxide finish for identification purposes.

- ・使用温度範囲:-10℃~150℃

- - Avoid using in chemicals, underwater, or in cleaning or degreasing environments.

SS (stainless steel) specifications

- - The chain body and main rollers are made of 18-8 stainless steel and are corrosion resistant.

- ・使用温度範囲:-20℃~400℃

- ・Lubricating is required.

Product List

*Click to display detailed information.

| Chain body specification |

Main unit roller |

Types of Plastic top rollers | Types of steel top rollers | Pitch mm |

Roller diameter mm |

Inner link Inner width mm |

|||

|---|---|---|---|---|---|---|---|---|---|

| Plastic Roller |

KV Roller |

Steel roller (Stainless steel roller *2) |

Lambda roller |

||||||

| Standard Series | |||||||||

| RS type | steel | RS40-TRP | --- | RS40-TR | RS40-TRLM | 12.70 | 7.92 | 7.95 | |

| RS50-TRP | --- | RS50-TR | RS50-TRLM | 15.875 | 10.16 | 9.53 | |||

| RS60-TRP | --- | RS60-TR | RS60-TRLM | 19.05 | 11.91 | 12.70 | |||

| RS80-TRP | --- | RS80-TR | RS80-TRLM | 25.40 | 15.88 | 15.88 | |||

| RS100-TRP | --- | RS100-TR | --- | 31.75 | 19.05 | 19.05 | |||

| Lambda Specification (LMC) *1 |

|||||||||

| RS type | steel | RS40-LMC-TRP | --- | RS40-LMC-TR | RS40-LMC-TRLM | 12.70 | 7.92 | 7.95 | |

| RS50-LMC-TRP | --- | RS50-LMC-TR | RS50-LMC-TRLM | 15.875 | 10.16 | 9.53 | |||

| RS60-LMC-TRP | --- | RS60-LMC-TR | RS60-LMC-TRLM | 19.05 | 11.91 | 12.70 | |||

| RS80-LMC-TRP | --- | RS80-LMC-TR | RS80-LMC-TRLM | 25.40 | 15.88 | 15.88 | |||

| RS100-LMC-TRP | --- | RS100-LMC-TR | --- | 31.75 | 19.05 | 19.05 | |||

| SS Series (Stainless steel) |

|||||||||

| RS type | stainless | RS40-SS-TRP | RS40-SS-TR-PKV | RS40-SS-TR | --- | 12.70 | 7.92 | 7.95 | |

| RS50-SS-TRP | RS50-SS-TR-PKV | RS50-SS-TR | --- | 15.875 | 10.16 | 9.53 | |||

| RS60-SS-TRP | RS60-SS-TR-PKV | RS60-SS-TR | --- | 19.05 | 11.91 | 12.70 | |||

| RS80-SS-TRP | --- | RS80-SS-TR | --- | 25.40 | 15.88 | 15.88 | |||

| RS100-SS-TRP | --- | RS100-SS-TR | --- | 31.75 | 19.05 | 19.05 | |||

Note

1. For convenience, the term "chain body" refers to the entire chain excluding the top roller.

2. *1 Even if the chain itself is a lambda specification, the steel top rollers must be oiled.

3. *2 If the chain body is SS Series, the rollers will be stainless steel.

When selecting sprocket specifications

It is necessary to select a sprocket specification that corresponds to the customer's operating environment and chain specifications.

Use standard steel RS sprockets with RS chains equipped with top rollers.

Please see the chain and sprocket compatibility chart here.