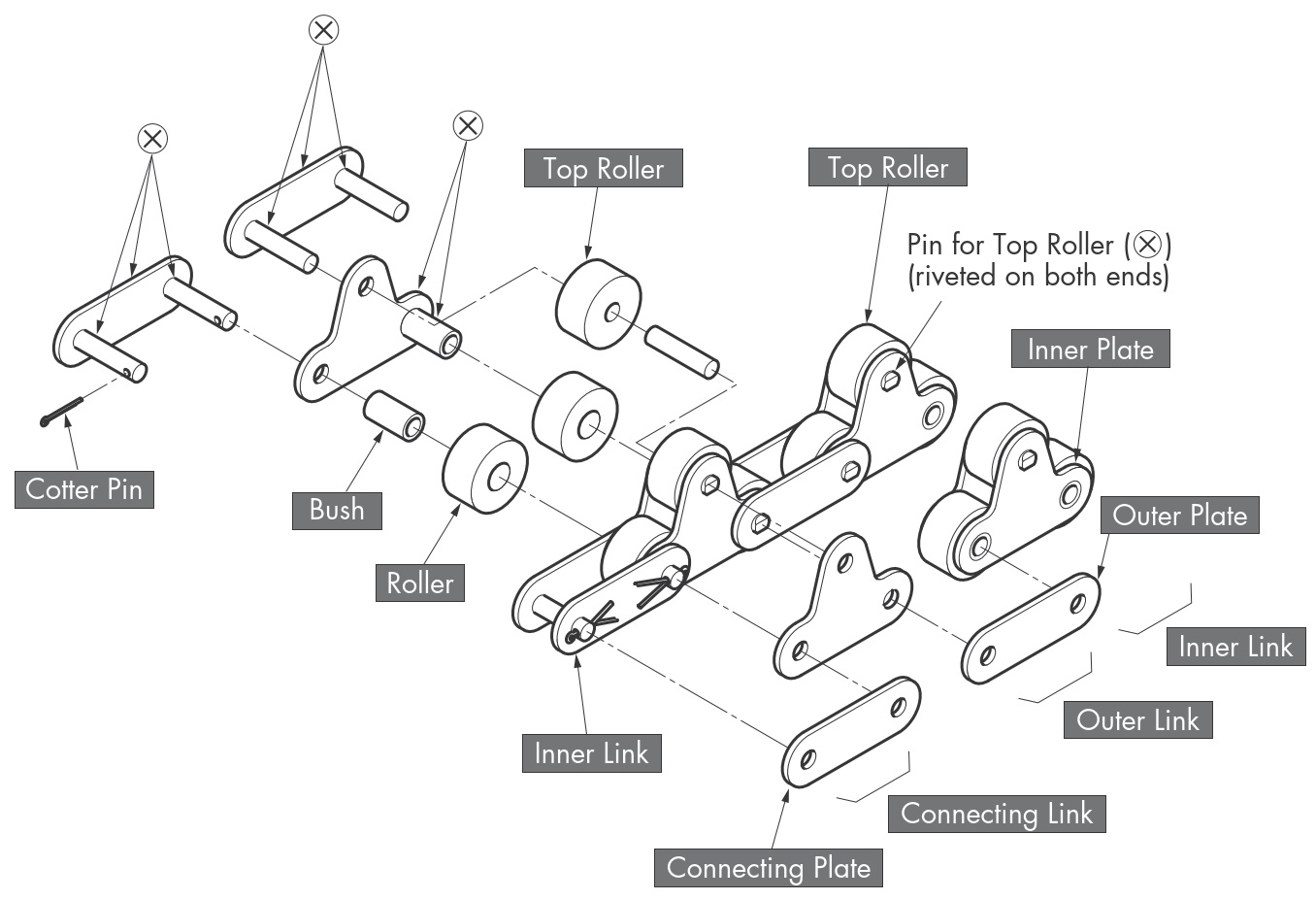

Double pitch withTop Roller

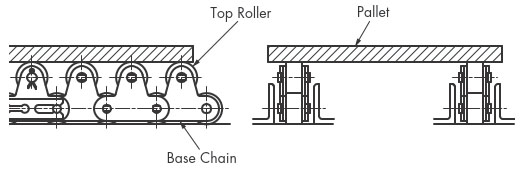

- Double pitch with top roller is a free flow type with Double pitch plate extended to the top and a freely rotating top roller attached to it.

It's a chain. - The width of the chain itself is smaller than other free flow chains, and the top roller is supported by plates on both sides, making it a sturdy free flow chain.

Suitable for conveyors. - Standard Series, lambda (Lube-free) specifications, and SS (stainless steel) specifications are available.

- * NP Series (nickel plating) are also available, so please contact us for details.

Purpose

- It is suitable for transporting heavy objects at low speeds, and is widely used in automobile production facilities in particular.

Catalogs and Instruction Manuals

About each specification

Standard Series

- - All parts of the chain body except for the rollers are made of heat-treated hardened steel.

- -You can choose between steel rollers (S, R) or plastic R rollers for the main body rollers.You can choose between Plastic Roller and steel rollers for the top rollers.

- Steel roller

- - All parts are made of steel and are heat-treated and hardened.

- ・使用温度範囲:-10℃~150℃

- ・Lubricating is required.

- Plastic R Roller (engineering plastic)

- - Lightweight (40% lighter than steel), low noise (5-7dB lower than steel)

- - Rolling resistance (30% reduction compared to steel)

- ・使用温度範囲:-10℃~80℃

- ・Oil must be applied between the pin and bushing. The engineering plastic roller is white.

Lambda (Lube-free) specification

- - The use of special oil-impregnated bush allows for long-term use Lube-free. (Oiling is required for steel top rollers.)

- -You can choose between steel rollers (S, R) or plastic R rollers for the main body rollers.You can choose between Plastic Roller and steel rollers for the top rollers.

- -allowable tension is the same as Standard Series, but the inner and outer plates are black oxide finish for identification purposes.

- ・使用温度範囲:-10℃~150℃

- - Avoid using in chemicals, underwater, or in cleaning or degreasing environments.

SS (stainless steel) specifications

- - The chain body and main rollers are made of 18-8 stainless steel and are corrosion resistant.

- - The main roller can be selected from stainless steel rollers (S, R) or plastic R rollers. The top roller can be selected Plastic Roller, KV rollers, and stainless steel rollers.

- Steel roller

- - The chain body and body rollers are made of stainless steel and are corrosion resistant.

- ・使用温度範囲:-20℃~400℃

- ・Lubricating is required.

- Plastic R Roller (engineering plastic)

- - Lightweight (40% lighter than steel), low noise (5-7dB lower than steel)

- - Rolling resistance (30% reduction compared to steel)

- ・使用温度範囲:-10℃~80℃

- ・Oil must be applied between the pin and bushing. The engineering plastic roller is white.

Product List

*Click to display detailed information.

| Chain body specification |

Main unit roller |

Types of Plastic top rollers | Types of steel top rollers | Pitch mm |

Roller diameter mm |

Inner link Inner width mm |

|||

|---|---|---|---|---|---|---|---|---|---|

| Plastic Roller |

KV Roller |

Steel roller (Stainless steel roller *2) |

Lambda roller |

||||||

| Standard Series | Double pitch | steel | RF2040S-TRP | --- | RF2040S-TR | RF2040S-TRLM | 25.4 | 7.92 | 7.95 |

| RF2050S-TRP | --- | RF2050S-TR | RF2050S-TRLM | 31.75 | 10.16 | 9.53 | |||

| RF2060S-TRP | --- | RF2060S-TR | RF2060S-TRLM | 38.1 | 11.91 | 12.7 | |||

| RF2080S-TRP | --- | RF2080S-TR | RF2080S-TRLM | 50.8 | 15.88 | 15.88 | |||

| RF2100S-TRP | --- | RF2100S-TR | --- | 63.5 | 19.05 | 19.05 | |||

| RF2040R-TRP | --- | RF2040R-TR | RF2040R-TRLM | 25.4 | 15.88 | 7.95 | |||

| RF2050R-TRP | --- | RF2050R-TR | RF2050R-TRLM | 31.75 | 19.05 | 9.53 | |||

| RF2060R-TRP | --- | RF2060R-TR | RF2060R-TRLM | 38.1 | 22.23 | 12.7 | |||

| RF2080R-TRP | --- | RF2080R-TR | RF2080R-TRLM | 50.8 | 28.58 | 15.88 | |||

| RF2100R-TRP | --- | RF2100R-TR | --- | 63.5 | 39.69 | 19.05 | |||

| Engineering plastics | RF2040RP-TRP | --- | RF2040RP-TR | --- | 25.4 | 15.88 | 7.95 | ||

| RF2050RP-TRP | --- | RF2050RP-TR | --- | 31.75 | 19.05 | 9.53 | |||

| RF2060RP-TRP | --- | RF2060RP-TR | --- | 38.1 | 22.23 | 12.7 | |||

| RF2080RP-TRP | --- | RF2080RP-TR | --- | 50.8 | 28.58 | 15.88 | |||

| RF2100RP-TRP | --- | RF2100RP-TR | --- | 63.5 | 39.69 | 19.05 | |||

| Lambda Specification (LMC) *1 |

Double pitch | steel | RF2040S-LMC-TRP | --- | RF2040S-LMC-TR | RF2040S-LMC-TRLM | 25.4 | 7.92 | 7.95 |

| RF2050S-LMC-TRP | --- | RF2050S-LMC-TR | RF2050S-LMC-TRLM | 31.75 | 10.16 | 9.53 | |||

| RF2060S-LMC-TRP | --- | RF2060S-LMC-TR | RF2060S-LMC-TRLM | 38.1 | 11.91 | 12.7 | |||

| RF2080S-LMC-TRP | --- | RF2080S-LMC-TR | --- | 50.80 | 15.88 | 15.88 | |||

| RF2040R-LMC-TRP | --- | RF2040R-LMC-TR | RF2040R-LMC-TRLM | 25.4 | 15.88 | 7.95 | |||

| RF2050R-LMC-TRP | --- | RF2050R-LMC-TR | RF2050R-LMC-TRLM | 31.75 | 19.05 | 9.53 | |||

| RF2060R-LMC-TRP | --- | RF2060R-LMC-TR | RF2060R-LMC-TRLM | 38.1 | 22.23 | 12.7 | |||

| RF2080R-LMC-TRP | --- | RF2080R-LMC-TR | --- | 50.80 | 28.58 | 15.88 | |||

| Engineering plastics | RF2040RP-LMC-TRP | --- | RF2040RP-LMC-TR | --- | 25.4 | 15.88 | 7.95 | ||

| RF2050RP-LMC-TRP | --- | RF2050RP-LMC-TR | --- | 31.75 | 19.05 | 9.53 | |||

| RF2060RP-LMC-TRP | --- | RF2060RP-LMC-TR | --- | 38.1 | 22.23 | 12.7 | |||

| SS Series (Stainless steel) |

Double pitch | stainless | RF2040S-SS-TRP | RF2040S-SS-TR-PKV | RF2040S-SS-TR | --- | 25.4 | 7.92 | 7.95 |

| RF2050S-SS-TRP | RF2050S-SS-TR-PKV | RF2050S-SS-TR | --- | 31.75 | 10.16 | 9.53 | |||

| RF2060S-SS-TRP | RF2060S-SS-TR-PKV | RF2060S-SS-TR | --- | 38.1 | 11.91 | 12.7 | |||

| RF2080S-SS-TRP | --- | RF2080S-SS-TR | --- | 50.8 | 15.88 | 15.88 | |||

| RF2100S-SS-TRP | --- | RF2100S-SS-TR | --- | 63.5 | 19.05 | 19.05 | |||

| RF2040R-SS-TRP | --- | RF2040R-SS-TR | --- | 25.4 | 15.88 | 7.95 | |||

| RF2050R-SS-TRP | --- | RF2050R-SS-TR | --- | 31.75 | 19.05 | 9.53 | |||

| RF2060R-SS-TRP | --- | RF2060R-SS-TR | --- | 38.1 | 22.23 | 12.7 | |||

| RF2080R-SS-TRP | --- | RF2080R-SS-TR | --- | 50.8 | 28.58 | 15.88 | |||

| RF2100R-SS-TRP | --- | RF2100R-SS-TR | --- | 63.5 | 39.69 | 19.05 | |||

| Engineering plastics | RF2040RP-SS-TRP | --- | --- | --- | 25.4 | 15.88 | 7.95 | ||

| RF2050RP-SS-TRP | --- | --- | --- | 31.75 | 19.05 | 9.53 | |||

| RF2060RP-SS-TRP | --- | --- | --- | 38.1 | 22.23 | 12.7 | |||

| RF2080RP-SS-TRP | --- | --- | --- | 50.8 | 28.58 | 15.88 | |||

| RF2100RP-SS-TRP | --- | --- | --- | 63.5 | 39.69 | 19.05 | |||

Note

1. For convenience, the term "chain body" refers to the entire chain excluding the top roller.

2. *1 Even if the chain itself is a lambda specification, the steel top rollers require oiling.

3. *2 If the chain body is SS Series, the rollers will be stainless steel.

When selecting sprocket specifications

It is necessary to select a sprocket specification that corresponds to the customer's operating environment and chain specifications.

In the case of double pitch chain with top rollers (main body R rollers), a special sprocket is required as the teeth of a standard Double pitch sprocket (for R rollers) will come into contact with the top roller.

For S-rollers, use standard steel Double pitch sprockets.

If the sprocket has 30 or more teeth, a standard steel RS sprocket can be used.

Please see the chain and sprocket compatibility chart here.