Q&A linear actuator

We have posted frequently asked questions from customers in Q&A format. Please click on the question to proceed to the answer.

Linipower Jack

Words in Q&Aof

| Q1 | Is Linipower Jack environmentally friendly? | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | Although it depends on the conditions of use and calculation standards, Linipower Jack generally operate on about one-third the electricity required compared to hydraulic types. | |||||||||||||||||||

| Q2 | Is this compliant with the RoHS Directive? | |||||||||||||||||||

| A2 | With the exception of some motor-equipped products, we are able to comply with the European RoHS Directive. Please contact us for more information. | |||||||||||||||||||

| Q3 | What is a rotation prevention specification? | |||||||||||||||||||

| A3 | In the standard specifications, if the shaft end is fixed or there is a mechanism to receive rotational force, the screw shaft will rise and fall without rotating, but if the screw shaft rotates, it will not rise and fall, so it is necessary to prevent the screw shaft of the jack from rotating. | |||||||||||||||||||

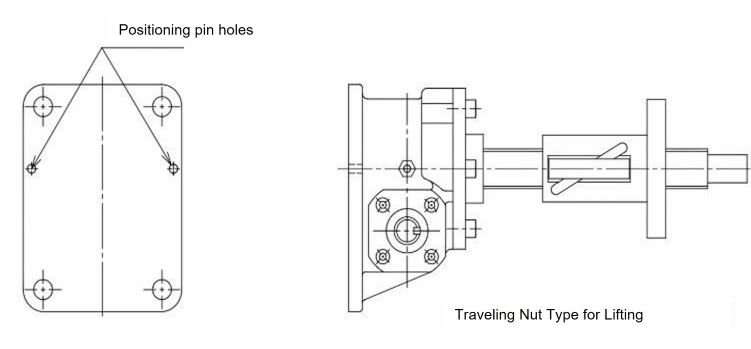

| Q4 | What is the traveling nut specification? | |||||||||||||||||||

| A4 | With the standard and anti-rotation specifications, the screw shaft rises and falls by rotating the nut, but with the traveling nut specification, the nut rises and falls by rotating the screw shaft. | |||||||||||||||||||

| Q5 | What is the maximum operating temperature? | |||||||||||||||||||

| A5 | Linipower Jack can be used when the jack surface temperature is between -15°C and 80°C during operation. | |||||||||||||||||||

| Q6 | Can Linipower Jack be manufactured for outdoor use? | |||||||||||||||||||

| A6 | Outdoor protection measures such as painting and sealing are possible, but if the product is in an environment where it will be exposed to direct water, please take measures such as providing a cover yourself. | |||||||||||||||||||

| Q7 | Is it possible to perform a push stop? | |||||||||||||||||||

| A7 | When a normal motor is used to stop by pressing, an impact occurs during pressing, which can cause a malfunction. | |||||||||||||||||||

| Q8 | Can the tip be used freely with the traveling nut specification? | |||||||||||||||||||

| A8 | Yes, it can be used. However, please be careful when using it as the allowable buckling load and allowable input rotation speed are limited. | |||||||||||||||||||

| Q9 | When linking two Linipower Jack jacks, do they need to have anti-rotation specifications? | |||||||||||||||||||

| A9 | No. In case of linked operation, be sure to provide a guide. | |||||||||||||||||||

| Q10 | Are there any problems with using it horizontally? | |||||||||||||||||||

| A10 | It can be used horizontally. | |||||||||||||||||||

| Q11 | What precautions should I take when installing Linipower Jack in linked operation? | |||||||||||||||||||

| A11 | Since multiple Linipower Jack will be used, please be careful to level the jacks, such as by adjusting the center height and input shaft height of multiple jacks. | |||||||||||||||||||

| Q12 | Is it possible to perform swing operation on Linipower Jack? | |||||||||||||||||||

| A12 | Swing operation is possible by using an I-shaped bracket at the tip and attaching it with a clevis bracket or trunnion bracket (optional). | |||||||||||||||||||

| Q13 | When should double-ended clevis supports be used? | |||||||||||||||||||

| A13 | The clevis support on both ends is the optimum installation for oscillating operation. Please use it for oscillating operation. | |||||||||||||||||||

| Q14 | I would like to use the JWB (Ball screw type) at Percentage duty cycle of 30% or more. Is this possible? | |||||||||||||||||||

| A14 | We can make suggestions after thoroughly checking your usage environment. | |||||||||||||||||||

| Q15 | Is it possible to cut one side of the input shaft, tap the shaft end, or plate it? | |||||||||||||||||||

| A15 | We can provide special-shaped products. We have a proven track record, so please contact us for more information. | |||||||||||||||||||

| Q16 | How much backlash does the input shaft have? | |||||||||||||||||||

| A16 | The backlash of the screw itself and the backlash of the worm gear become backlash on the input shaft. | |||||||||||||||||||

| Q17 | Can the jack be shipped with a motor or Gear Motor attached to the input shaft? | |||||||||||||||||||

| A17 | JWM (Trapezoidal Screw type), JWB (Ball screw type), and JWH (High lead ball screw type) can be manufactured with optional motors and gear motor. | |||||||||||||||||||

| Q18 | Is it possible to turn the jack input shaft with a manual handle? | |||||||||||||||||||

| A18 | A manual handle is available as an option. It can be used with a self-locking Trapezoidal Screw type. | |||||||||||||||||||

| Q19 | I would like to attach a servo motor to raise and lower the product, but are there any precautions I should take? | |||||||||||||||||||

| A19 | Servo motors are suitable for high-speed, high-frequency operation. | |||||||||||||||||||

| Q20 | Can oil lubrication specifications be manufactured? | |||||||||||||||||||

| A20 | It can be manufactured as a special-shaped product. | |||||||||||||||||||

| Q21 | How often should I change the grease in the reducer? | |||||||||||||||||||

| A21 | For frame numbers 025 and above, a guideline for the lubrication cycle is set based on the frequency of daily use.

| |||||||||||||||||||

| Q22 | How do I change the grease in the reducer? | |||||||||||||||||||

| A22 | Remove the hexagon socket plug and add grease until the grease poured into the grease nipple overflows from the hole in the removed hexagon socket plug. | |||||||||||||||||||

| Q23 | Can self-locking be expected with JWM (Trapezoidal Screw type)? | |||||||||||||||||||

| A23 | JWM (Trapezoidal Screw type) is theoretically self-locking, but vibration, shock, etc. may cause the self-locking function to become ineffective. | |||||||||||||||||||

| Q24 | What happens if I exceed the stroke range? | |||||||||||||||||||

| A24 | In the case of standard specifications, the JWB (Ball screw type) and JWH (High lead ball screw type) have a stopper on the screw so it will not fall out, but the JWM (Trapezoidal Screw type) may have a problem with the screw falling out. | |||||||||||||||||||

| Q25 | What are the advantages of the JWH (High lead ball screw type)? | |||||||||||||||||||

| A25 | The screw lead is larger than the regular JWB (Ball screw type), making it suitable for high-speed operation. | |||||||||||||||||||

| Q26 | Can Linipower Jack screw withstand a lateral load? | |||||||||||||||||||

| A26 | The JWB (Ball screw type) cannot withstand lateral loads, but the JWM (Trapezoidal Screw type) can withstand a certain amount of lateral load when stationary. | |||||||||||||||||||

| Q27 | Why does the bellows for the JWH (High lead ball screw type) have special specifications? | |||||||||||||||||||

| A27 | The JWH (High lead ball screw type) is designed for high-speed operation, so it is necessary to provide an air hole to quickly release the air inside the bellows, and this is a special specification. | |||||||||||||||||||

| Q28 | Are there any standard bellows with traveling nuts? | |||||||||||||||||||

| A28 | The traveling nut specification is designed so that the nut moves on the screw shaft, so the length of the bellows is determined by the stroke of movement, and the diameter of the bellows is determined by the installation direction of the nut. | |||||||||||||||||||

| Q29 | When replacing the bellows, the table-shaped End fitting won't come off. What should I do? | |||||||||||||||||||

| A29 | The table-shaped End fitting is coated with adhesive to prevent loosening of the screws and screwed onto the end of the screw shaft. | |||||||||||||||||||

| Q30 | To make it easier to install the jack, is it possible to provide a spigot on the jack installation surface, for example? | |||||||||||||||||||

| A30 | We can also manufacture products with a spigot. The spigot is a convex part with tolerances, which is suitable for improving reproducibility and installation accuracy when disassembly and assembly of equipment is required. We can also accommodate customer requests for spigot diameter and dimensional tolerances, so please contact us. | |||||||||||||||||||