Q&A Mechanical protector

We have posted frequently asked questions from customers in Q&A format. Please click on the question to proceed to the answer.

Shock Guard / Shock Guard Coupling

Words in Q&Aof

| Q1 | What is the RoHS compliance status? |

|---|---|

| A1 |

The TGB and TGX series are already compatible, and the TGM series is being gradually replaced. If you require a RoHS compliant product in the TGM series, please specify "RoHS compliant" when placing your order. Back to Questions |

| Q2 | What is the allowable temperature range? |

| A2 |

Body temperature: -10℃ to 100℃. Some coupling specifications have an upper limit of 80℃. If the temperature is outside this range, please contact us. Back to Questions |

| Q3 | Please tell me about the lifespan. |

| A3 |

It depends on the conditions of use, so we cannot give you a definite answer. Back to Questions |

| Q4 | Are there any precautions to take when using the TGM series in an environment where it may come into contact with water, oil, etc.? |

| A4 |

The TGM series is designed with seals and packing to prevent dust, oil, and water from getting into the parts inside the case, but please note that the camshaft and adjustment screws exposed from the case are susceptible to corrosion and rust due to water and water vapor. Return to Questions |

| Q5 | I purchased a TGB30-L, but when I checked it on the actual machine, the torque was insufficient. I would like to change it to a TGB30-H. What should I do? |

| A5 |

The only part that is different between the TGB30-L and TGB30-H is the spring. If you replace the spring, it will become a TGB30-H, but the torque scale attached to the product for adjusting the set torque will no longer match. There is no problem in using it as is, but if you need a torque scale, please return it to us and we will replace the disc spring, set the torque to the min. point, re-attach the torque scale, and reship it to you. Please contact your nearest dealer. Back to Questions |

| Q6 | I was using Shock Guard, but it didn't trip even when overloaded. What is the probable cause? |

| A6 |

The adjustment nuts (bolts) may have been tightened too much. |

| Q7 | I would like to use Shock Guard coupling, but is there a specific direction in which it should be installed on the driven machine side and the driving machine side? |

| A7 |

There is no orientation, so you can use it no matter which way you attach it. |

| Q8 | I would like to use the highly accurate TGX for the high-speed axis, but I am unable to stop it instantly after tripping. Is there any good way to do this? |

| A8 |

Special specification products are available that allow complete release without backlash. Please contact us for details. Back to Questions |

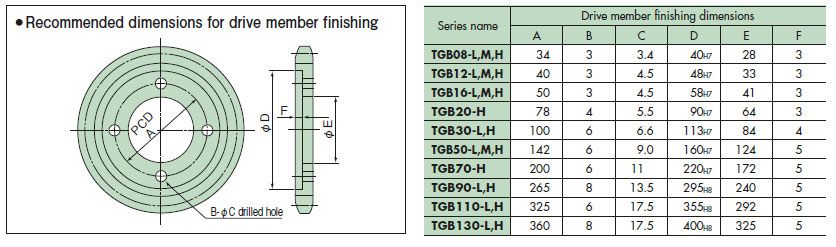

| Q9 | I would like to install a sprocket on the TGB series. What are the recommended machining dimensions for the sprocket? |

| A9 | Back to Questions |