Q&A Reducer

We have posted frequently asked questions from customers in Q&A format. Please click on the question to proceed to the answer.

Worm reducer

Words in Q&Aof

technology

option

Selection

Lubrication

Handling

| Q1 | What is the efficiency of a worm reducer? |

|---|---|

| A1 |

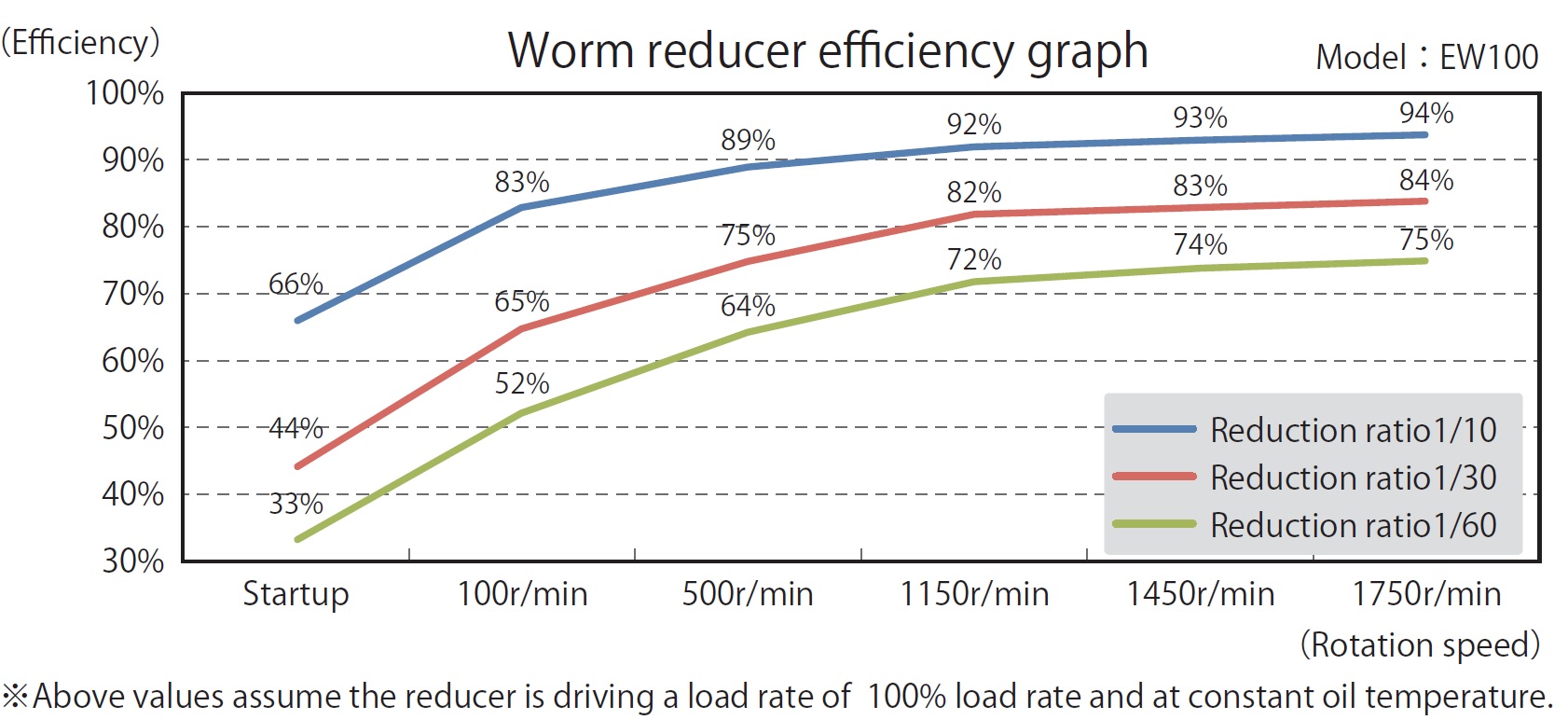

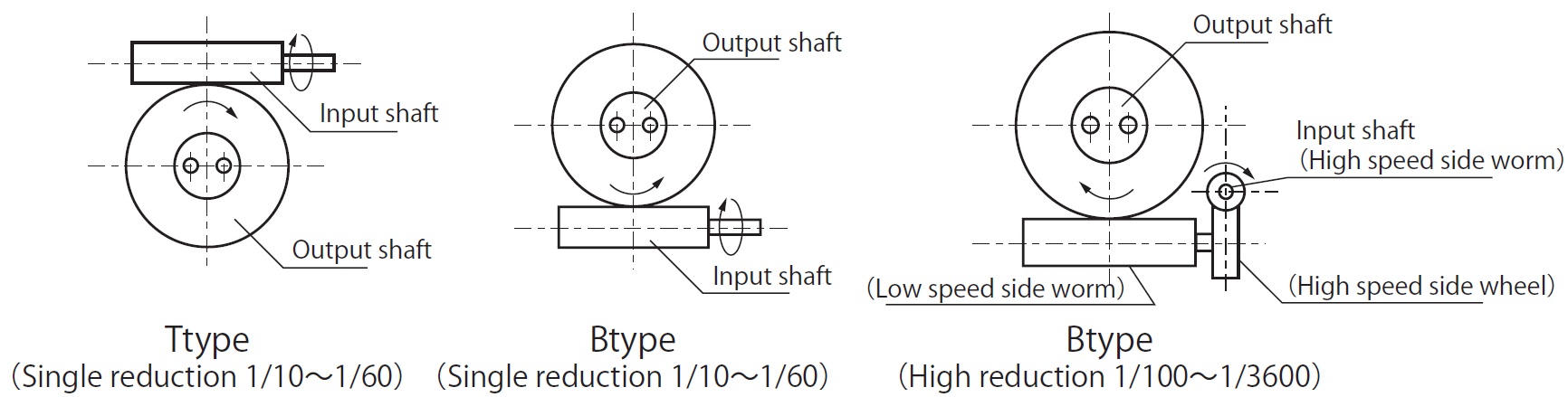

The efficiency of a worm reducer varies depending on the reduction ratio and the rotational speed of the input shaft (motor). For example, when the EW100T10R (size 100, reduction ratio 1/10) is input at 1,750 r/min, the operating efficiency is over 90%, and when input at 100 r/min, the operating efficiency is around 80%. These can be calculated from kW ratings table in the catalog. |

| Q2 | What reduction ratio can be expected to achieve self-locking effects? |

| A2 |

Generally, a reduction ratio of 1/60 or 1/50 is expected to provide a self-locking effect. However, this is considered to be a completely stopped state with no vibrations. Our worm reducers are designed with efficiency in mind, so a reduction ratio of 1/60 can be expected to provide a self-locking effect. If you require even more emphasis on self-locking, please contact us for information on strengthened self-locking specifications. For details, please refer to our worm reducer catalog (Tsubaki Troi Drive Worm Power Drive). Back to Questions |

| Q3 | What is the rotational relationship between the input and output shafts of a worm reducer? |

| A3 |

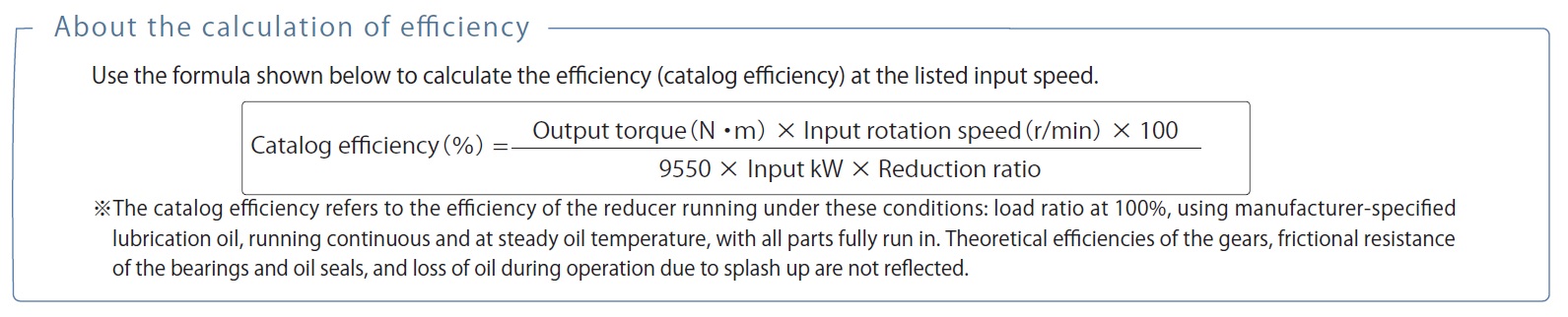

All of our standard worm gears are right-hand helix, and the rotational relationship between the input and output shafts is as follows: It can also be used in both clockwise and counterclockwise directions. Back to Questions |

| Q4 | What is the rotational unevenness (angular velocity fluctuation rate) of a worm reducer? |

| A4 |

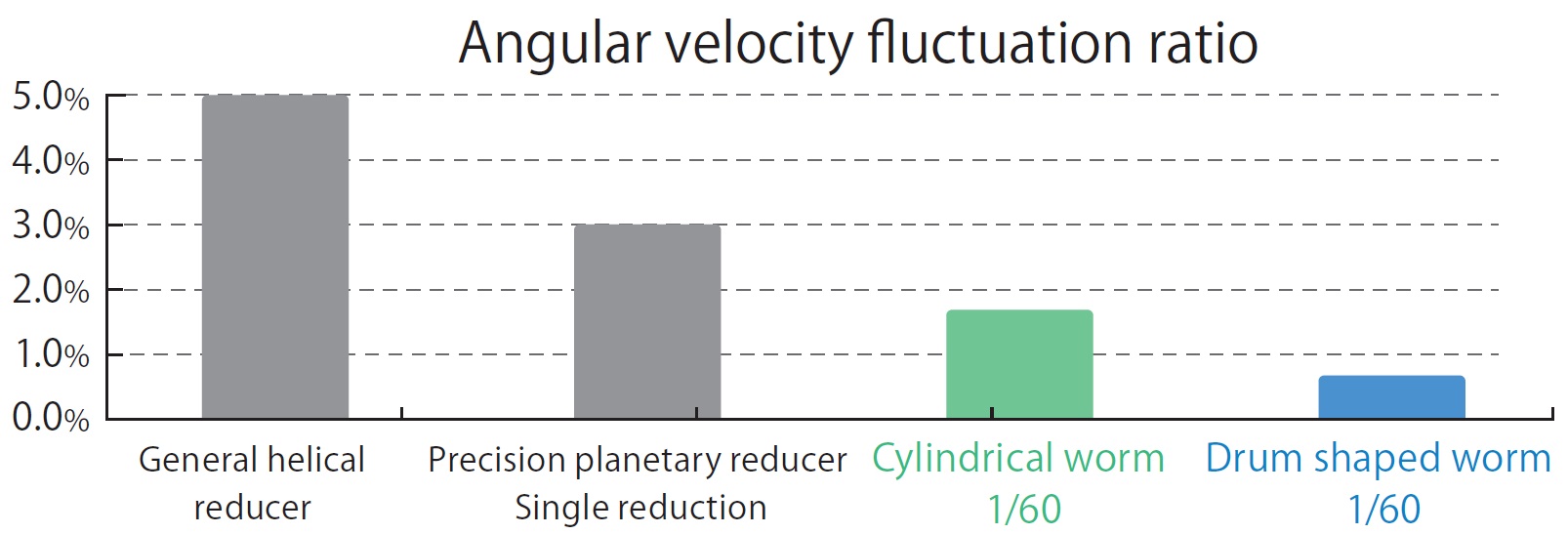

Worm Power Drive (Cylindrical Worm) have smaller rotational fluctuations (angular velocity fluctuation rate) than other gears, at approximately 1 to 2% for Cylindrical Worm. In addition, because Troi Drive (Troidal Worm) has a larger number of simultaneously meshing teeth, it has even higher accuracy than Cylindrical Worm at approximately 0.5%. |

| Q5 | What applications is the output shaft Power-Lock specification suitable for? |

| A5 |

The output shaft Power-Lock specification combines a hollow shaft with a friction type fastener (Tsubaki Power-Lock SL series). Power-Lock specifications are suitable for applications where a moment of inertia is applied and where key fastening would cause key wear. Because it is a friction type, it will not wear out like a key. On the other hand, when using it in an elevator or similar, although this is not usually a problem, there is a risk of it falling if there is a problem with the installation, so we recommend that you install a separate safety device on the driven shaft side. The applicable models are the hollow shaft type SW, EW, and TD series. Croise Motor are also available, so please contact us for more information. Back to Questions |

| Q6 | What is the difference between the low backlash specification and the standard product? |

| A6 |

Low backlash specifications are available for the EW, SW, TD series and TERVO. The difference from the standard product is that the thrust gap of the worm shaft is reduced to reduce backlash in the gear section. It is possible to further reduce backlash by manufacturing a new reducer case or worm gear, so please contact us. Back to Questions |

| Q7 | Can I expect a self-locking effect with the two-stage worm reduction ratio (EW100B600L-R)? Also, if the self-locking effect cannot be expected, is it possible to make it a special product? |

| A7 |

The reduction ratio of the two-stage worm reducer is a combination of (1st stage) 1/20 x (2nd stage) 1/30. As a special product, it is possible to change the combination of reduction ratios between the first and second stages. These combinations use standard gears and simply change the combination, so there is little impact on price or delivery. Back to Questions |

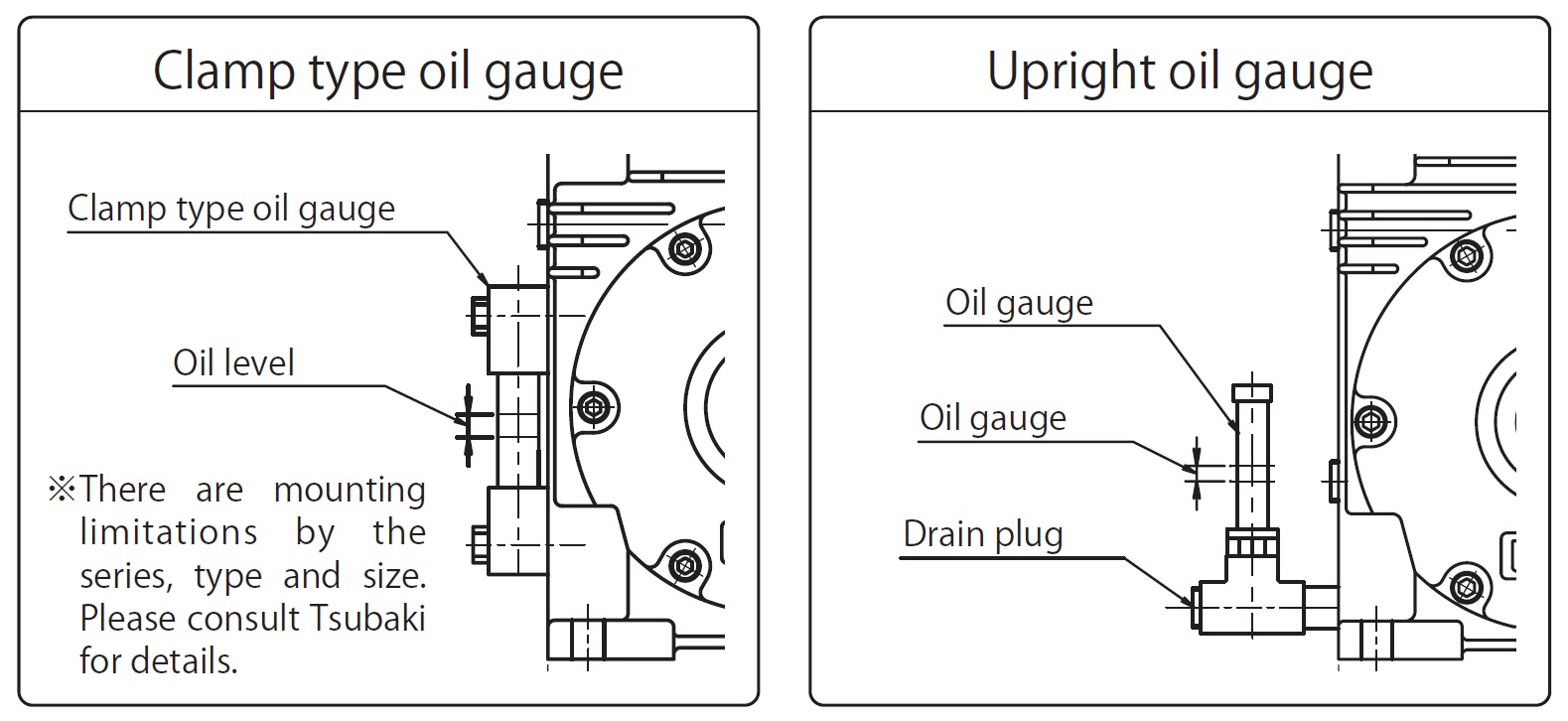

| Q8 | Oil gauges are easy to see from the front, but are there any that are easy to see from the side? |

| A8 |

The standard oil gauge is a red-circle type that makes it easy to check the oil level from the front, but clamp-type and vertical oil gauges are also available as options, making it easier to check the oil level from the side. The clamp-type oil gauge is shipped as an accessory as there is a risk of it being damaged during shipping or transportation. In this case, a blind plug is installed to prevent oil from overflowing, so please replace it before use. |

| Q9 | Is it possible to have a special reduction ratio or left-hand twist specifications? |

| A9 |

We have a lot of experience with special reduction ratio specifications (e.g. 1/8.0, etc.). |

| Q10 | What conditions must be met when selecting a worm reducer? |

| A10 |

As with other reducers, there are no special requirements for selecting a worm reducer. The main conditions are: 1) device name, 2) motor capacity and rotation speed, 3) output shaft torque or load torque, 4) output shaft rotation speed or reduction ratio, and 5) output shaft shape and shaft arrangement. However, if the moment of inertia is large, or if it is used in an elevating drive or inverting mechanism, care must be taken. Please contact us for details. Back to Questions |

| Q11 | I am thinking of using a worm reducer by hand. Is this possible? |

| A11 |

It is possible to use the worm reducer by turning it by hand, but for transmission capacity please refer to the value for 100 r/min in the transmission capacity table in the catalog. When using it for elevators or inverting machines, we recommend selecting a reduction ratio that will allow for self-locking, and also installing a holding brake to ensure safety. Back to Questions |

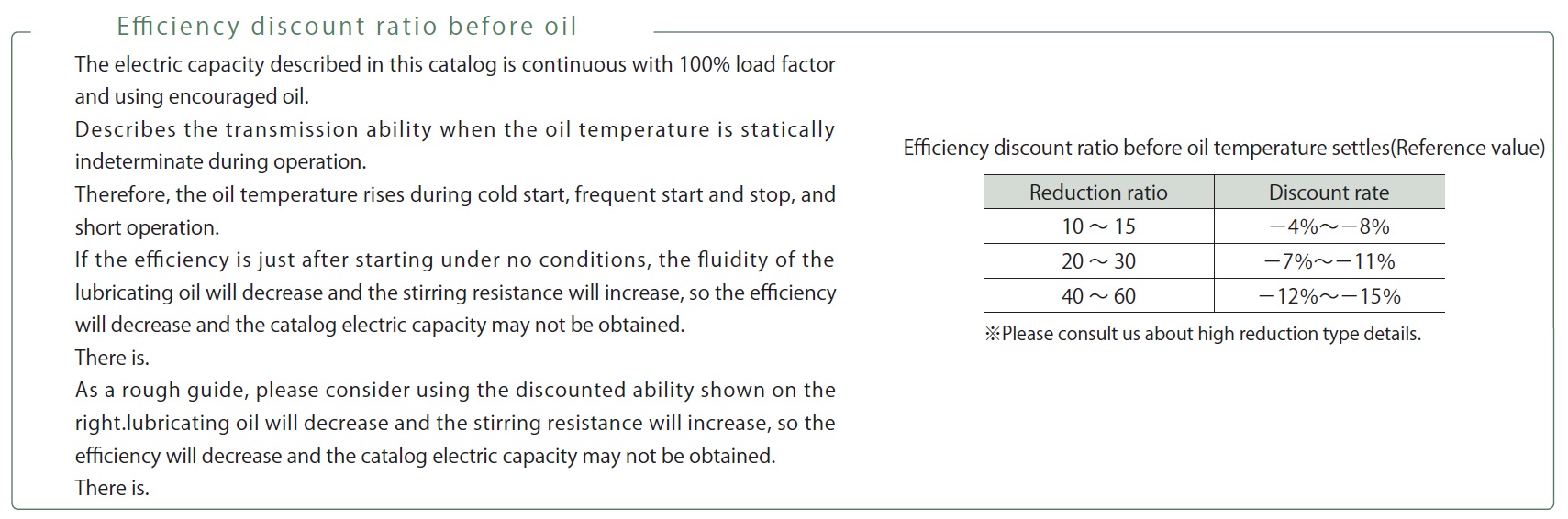

| Q12 | I am considering using a worm reducer in an elevator, but will the efficiency when cold be the same as the catalog value? |

| A12 |

The transmission capacity of the worm reducer is under continuous operation at 100% load with stable oil temperature. When using in cold conditions, efficiency will decrease, so please select by deducting the power from kW ratings table. The discount rate will vary depending on the reduction ratio, but it will range from -4% to a maximum of -15%. Back to Questions |

| Q13 | I would like to replace a product from another company. Do you have any information available? |

| A13 |

Please make use of the replacement website for equivalent products from other manufacturers. |

| Q14 | I would like to replace my old product, but do you have any information? |

| A14 |

We have a website where Search previous model No., so please make use of it. |

| Q15 | How should I clean the inside of the case when changing the lubricant? |

| A15 |

Follow the steps below to clean the inside of the case.

*When working at high temperatures, follow the instructions in the Instruction Manuals and be careful not to get burned. Back to Questions |

| Q16 | Is it possible to change to a different brand of lubricant when changing? |

| A16 |

Lubrication is extremely important for the capacity, lifespan, and efficiency of worm reducers, so be sure to use lubricants specified by our company. Also, avoid mixing oils with other brands as this may reduce performance and lifespan. |

| Q17 | Where can I purchase the dedicated lubricant (Daphne Alpha Oil TE***)? How many liters can I purchase it in? |

| A17 |

It can also be purchased from Tsubakimoto Chain dealers or Idemitsu Purchases can be made in 4L increments through Tsubakimoto Chain's retailers, but in 20L increments through Idemitsu Back to Questions |

| Q18 | Is it possible to fill the container with food-grade lubricant (H1 grade)? |

| A18 |

It is possible to specify specifications that include food-grade lubricant (H1 grade). In addition, we will provide an estimate for this product. Back to Questions |

| Q19 | I have purchased a worm reducer, but are there any restrictions on the installation direction? |

| A19 |

There are restrictions on the installation direction depending on the model. Also, please check the catalog to see if there are any restrictions on the mounting position. Back to Questions |

| Q20 | What is the role of the pressure vent? Also, is it delivered already installed? |

| A20 |

The pressure vent releases pressure inside the reducer. If it is blocked by a plug or other object, the pressure inside the reducer cannot be released, which may result in oil leaks from the oil seal or other parts. The pressure vent is attached to the product when it is delivered, so please be sure to install it before operation. Back to Questions |

| Q21 | If I want to update the worm reducer I am currently using, do I only need to provide the product model number? |

| A21 |

Since specifications may differ even for the same model number, please inform us of the information written on the reducer nameplate. Please provide the following information: ① Model number, ② Reduction ratio, ③ Serial number, ④ Drawing number. |