Troubleshooting sprocket and Pin gear drive

Sprocket

| 1 | The chain rides up onto the sprocket |

|---|

| Cause 1 | Chain and sprocket are not compatible | Solution | Replace the chain or sprocket with the correct size. |

|---|---|---|---|

| Cause 2 | Chain wear and elongation or sprocket tooth wear | Solution | Replace with a new one. |

| Cause 3 | Insufficient winding angle | Solution | The winding angle shall be 120° or more or 3 teeth or more. |

| Cause 4 | Chain and sprocket center distance | Solution | After inspection, make corrections. |

| 2 | There is an abnormal noise |

|---|

| Cause 1 | Improper installation of sprockets or shafts | Solution | Check and correct. |

|---|---|---|---|

| Cause 2 | Significant wear on the chain or sprockets | Solution | Replace the entire chain and sprockets with new ones. |

| Cause 3 | Lube-free or improper oil supply | Solution | Provide proper lubrication according to the operating conditions |

| 3 | The chain gets wrapped around the sprocket (it's difficult to separate). |

|---|

| Cause 1 | Chain wear and elongation or sprocket wear | Solution | Replace the chain and sprockets with new ones. |

|---|

| 4 |

|---|

| Cause 1 | Poor installation | Solution | Correct the installation of sprockets, shafts, etc. |

|---|---|---|---|

| Cause 2 | The chain is pushed sideways | Solution | Eliminate the cause of the pressure and change to a chain with guide rollers. |

| Cause 3 | Sprocket misalignment | Solution | Remove the chain and correct the centering of the drive and driven sprockets. |

| Cause 4 | Runout due to poor machining accuracy of sprocket shaft hole | Solution | After checking for defects, correct them and replace with a new sprocket. |

| Cause 5 |

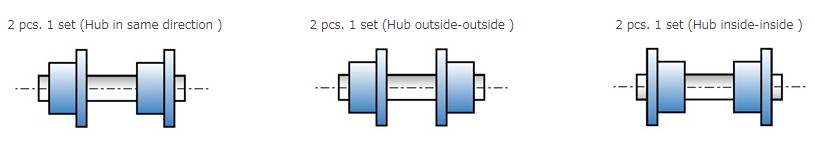

Keys are out of phase |

Solution |

When using two or more sprockets in parallel on the same shaft, the sprocket teeth should be in phase. When installing, check the hub direction and align the keyway. Mark the mating sprockets to manage them. |

| 5 | Wear of sprocket tooth root and tooth bearing surface |

|---|

| Cause 1 | Chain wear | Solution | Replace the chain and sprockets at the same time. |

|---|---|---|---|

| Cause 2 | Insufficient number of meshing teeth | Solution | Increase the number of teeth on the sprocket. |

| Cause 3 | Uses BF chain (without rollers) | Solution | Change to RF chain (with rollers). |

| Cause 4 | Tooth hardness is insufficient to withstand wear inclusions and excessive loads | Solution | Use hardened tooth tips or block replaceable tooth types. |

| Cause 5 | Incompatible sprocket and chain | Solution | Replace the chain or sprocket with the correct size. |

| 6 | Poor articulation |

|---|

| Cause 1 | Chain deformation due to improper installation | Solution | Check and correct the installation of the sprocket and shaft. |

|---|

| 7 | The chain sticks and slips (stick-slip phenomenon). |

|---|

| Cause 1 | Variation in chain rolling friction coefficient | Solution | Replace the sprocket with a new one. |

|---|---|---|---|

| Cause 2 | Speed fluctuation due to polygonal movement | Solution | The number of teeth on the drive sprocket must be 12T or more. |

| 8 | One of the Inner link or pins of an NF block chain or BF chain (without rollers) wears out. |

|---|

| Cause 1 | Internal tension increases when meshing with the sprocket. | Solution |

|---|

| 9 | Rapid plate fracture |

|---|

| Cause 1 | Solution |

|

|---|

| 10 |

|---|

| Cause 1 | Hub strength is insufficient | Solution | Check and correct the hub diameter and bore diameter, then replace with a new sprocket. |

|---|

The sprocket only functions as a product when used in conjunction with a chain.

We also have Troubleshooting pages for each chain, so please refer to them as well.