Troubleshooting Cable Carrier (CABLEVEYOR)

| 1 | The main link is broken |

|---|---|

| 2 | The cable is broken |

| 3 | The main link of Gliding arrangement model was broken. |

| 4 | Cables and hoses get twisted and tangled inside Cable Carrier (CABLEVEYOR) |

| 1 |

|---|

| Cause 1 |

The deflection of the free span section caused (1) and (2) to result in excessive impact force.

|

Solution |

*Please check here for applicable varieties. |

|---|---|---|---|

| Cause 2 | The endurance life was reached during operation. | Solution | Compare the deflection of the free span section with the limit value (guideline), and if it reaches the limit value, replace it with a new one. |

| 2 |

|---|

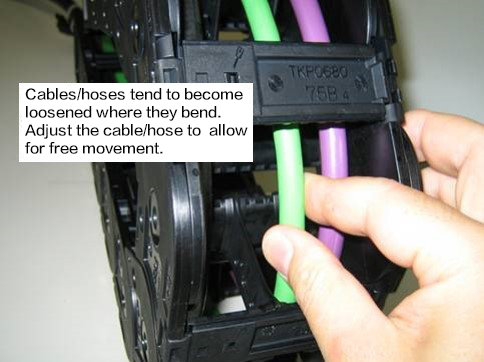

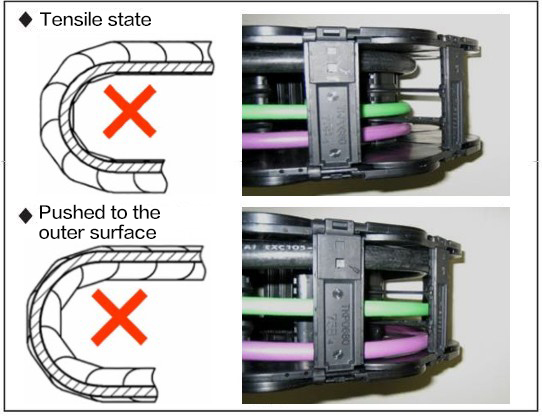

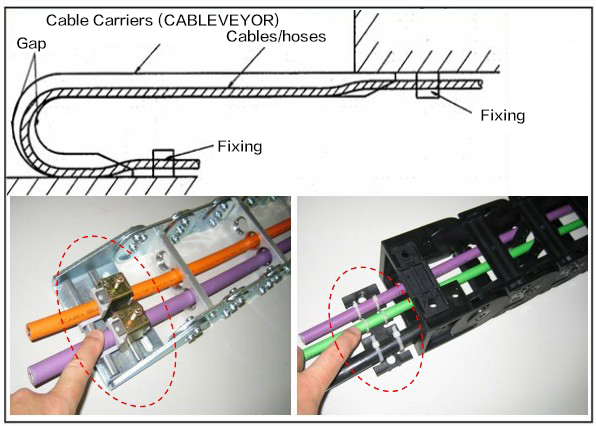

| Cause 1 | The cable hose protruded to the inside and outside of Cable Carrier (CABLEVEYOR) and interfered with peripheral equipment. | Solution |

|

|---|---|---|---|

| Cause 2 |

The inner cable hose was crushed and excessive compressive force was repeatedly applied. |

||

| Cause 3 | The load was applied because the bending radius radius of Cable Carrier (CABLEVEYOR) was smaller than the allowable bending bending radius of the cable/hose. | Solution | Make bending radius of Cable Carrier (CABLEVEYOR) larger than the allowable bending radius of the cable/hose. |

| 3 |

|---|

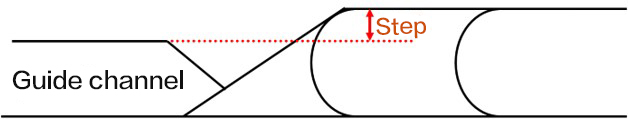

| Cause 1 |

There was a large difference in height at the joint between the rail along which the inner surface of Cable Carrier (CABLEVEYOR) slides and Cable Carrier (CABLEVEYOR) fixed end link. This increased the sliding resistance when transferring from the rail to the fixed-end link. |

Solution |

Eliminates the step between guide channel and Cable Carrier (CABLEVEYOR). For details, please refer to Instruction Manuals. |

|---|---|---|---|

| Cause 2 |

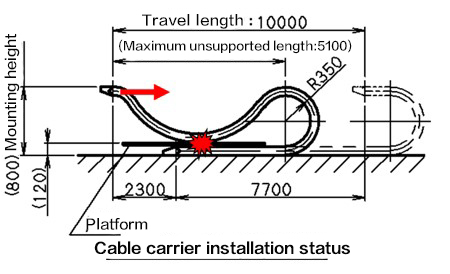

The moving end and installation height of Cable Carrier (CABLEVEYOR) were higher than our recommended values. This caused an excessive bending moment to act on the free span section. |

Solution | The installation height must be within our recommended range. |

| Cause 3 | Dust and other particles accumulated on Cable Carrier (CABLEVEYOR) running surface increased the running resistance. | Solution |

Avoid dust accumulation.

|

| 4 | Cables and hoses get twisted and tangled inside Cable Carrier (CABLEVEYOR) |

|---|

| Cause 1 |

Dividers were not used to separate the cables and hoses. |

Solution | Install partitions and store cables and hoses so that there is one cable per space as much as possible. |

|---|---|---|---|

| Cause 2 | Since the cable was not used for transportation, the core wires were untwisted, causing the cable to become serpentine. | Solution | Highly flexible cable for mobility with excellent durability and ability to withstand repeated bending - Use a hose. |