Troubleshooting Small size conveyor chain

If the chain or sprocket is severely damaged or broken, replace it with a new one by taking the following measures.

General

Plate related

| 8 | Rapid plate fracture |

|---|---|

| 9 | Cracks appear in the plate (fatigue) (perpendicular to the tensile direction) |

| 10 | Plate hole deformation |

| 11 | Stress corrosion cracking (bow-shaped cracks in the plate) |

Pin Related

| 12 | The pin breaks |

|---|---|

| 13 | Pin rotation or jumping out |

Bush and roller related

| 14 | Roller bushing cracks (falls off) |

|---|---|

| 15 | The roller does not rotate, or one side of the roller is worn |

| 16 | The roller opens |

| 17 | The roller becomes drum-shaped |

General

| 1 |

[Click to enlarge] |

The chain rides up onto the sprocket |

|---|

| Cause 1 | Chain and sprocket are not compatible | Solution | Replace the chain or sprocket with the correct size. |

|---|---|---|---|

| Cause 2 | Significant overload | Solution | Reduce the load (by oiling the driven machine, etc.), or increase No. of strands in the chain or increase its size. |

| Cause 3 | Chain wear and elongation or sprocket tooth wear | Solution | Replace with a new one. |

| Cause 4 | Insufficient winding angle | Solution | The winding angle shall be 120° or more or 3 teeth or more. |

| Cause 5 | Insufficient back tension | Solution | Installation and adjustment of catenaries and take-ups. |

| Cause 6 | Chain and sprocket center distance | Solution | After inspection, make corrections. |

| 2 | There is an abnormal noise |

|---|

| Cause 1 | Improper installation of sprockets or shafts | Solution | Check and correct. |

|---|---|---|---|

| Cause 2 | Loose chain casing or bearings | Solution | Retighten all bolts and nuts. |

| Cause 3 | Chain slack is too much or too little | Solution | Adjust the center distance to obtain the optimum slack. |

| Cause 4 | Significant wear on the chain or sprockets | Solution | Replace the entire chain and sprockets with new ones. |

| Cause 5 | Lube-free or improper oil supply | Solution | Fill with oil according to the conditions of use. |

| Cause 6 | Interference between the chain or moving part and the casing | Solution | After inspection, make corrections. |

| Cause 7 |

Poorly configured guardrails |

Solution | After inspection, make corrections. |

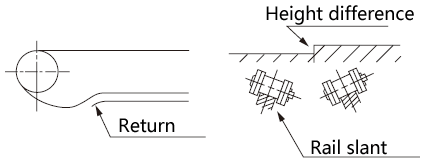

| 3 |

[Click to enlarge] |

The chain gets wrapped around the sprocket (poor release) |

|---|

| Cause 1 |

Excessive chain slack |

Solution | Adjust the chain length or center distance. Attach the tensioner. |

|---|---|---|---|

| Cause 2 | Chain wear and elongation or sprocket wear | Solution | Both will be replaced with new ones. |

| Cause 3 | Chain and sprocket mismatch | Solution | Replace with a new one. |

| Cause 4 | Poor bending due to rust Improper lubrication, bad atmosphere |

Solution | After replacing the chain, protect it from the atmosphere by oiling and casing it. |

| 4 | Wear on the inside of the chain plates and the sides of the sprocket teeth |

|---|

| Cause 1 | Poor installation | Solution | Correct the installation of sprockets, shafts, etc. |

|---|---|---|---|

| Cause 2 |

The chain is pushed sideways |

Solution | Eliminate the cause of the pressure and change to a chain with guide rollers. |

| 5 | Wear on the side of the chain plates or pin heads |

|---|

| Cause 1 |

Improper installation of guides, etc. |

Solution | Check the condition of the guide and increase the gap between the guide and the chain. |

|---|

| 6 |

[Click to enlarge] |

Chain bending is poor |

|---|

| Cause 1 | Roller chain deformation due to improper installation | Solution | Inspect and correct the installation condition. |

|---|---|---|---|

| Cause 2 | Wear debris and dirt buildup due to improper lubrication (e.g. grease) | Solution | Remove the chain, clean it and properly oil it. |

| Cause 3 | Overload, bent pin, broken bush | Solution | Reduce the load or increase the chain size or No. of strands. |

| Cause 4 | Corrosion and rust | Solution | Attach a casing to protect the chain. |

| Cause 5 | Insufficient lubrication | Solution | Lubricate sufficiently. |

| Cause 6 | Foreign objects and transported materials get stuck in the clearance | Solution | Protect the chain by installing a casing, etc. |

| Cause 7 | High temperature use | Solution | Ensure proper clearance (please consult with us). |

| 7 | Expansion of the inner width of the plate |

|---|

| Cause 1 |

Uneven load or significant overload due to improper installation |

Solution | Replace with a new one and correct the installation. |

|---|

Plate related

| Cause 1 | Excessive shock load | Solution | Reduce the impact load by making the start and stop smoother (by installing a shock absorber, etc.). Increase the size of the chain or No. of strands. |

|---|---|---|---|

| Cause 2 | Chain vibration | Solution | Install devices to prevent vibration (tensioners, idlers, etc.). |

| Cause 3 | corrosion | Solution | Replace with a new one. Protect the chain with a casing. Clean and oil the chain regularly. |

| 9 | Cracks appear in the plate (fatigue) (perpendicular to the tensile direction) |

|---|

| Cause 1 | A load greater than the maximum allowable load is applied | Solution | Avoid excessive loads or excessive repeated loads, or increase the size of the chain or No. of strands. |

|---|---|---|---|

| Cause 2 | Repeated loads are applied to the attachment | Solution | Avoid overloading, or increase the size of the chain and increase allowable load of the attachment. |

| 10 |

[Click to enlarge] |

Plate hole deformation |

|---|

| Cause 1 | overload | Solution | Replace with a new one. Eliminate the cause of overload. |

|---|

| 11 |

[Click to enlarge] |

Stress corrosion cracking (bow-shaped cracks in the plate) |

|---|

| Cause 1 | Use in acidic or alkaline environments (This is not due to the effect of repeated loading.) |

Solution | Replace with a new one. Protect the chain from the atmosphere with a casing or similar. Consideration of specifications that are highly resistant to stress corrosion cracking. |

|---|

Pin Related

| Cause 1 | Large impact load | Solution | Reduces shock and makes starting and stopping smoother. |

|---|---|---|---|

| Cause 2 | Repeated load exceeding the pin's fatigue limit | Solution | Avoid excessive repeated loads, or increase the size or No. of strands of strands of chain. |

| Cause 3 | corrosion | Solution | Install the casing. Clean and oil the chain regularly. |

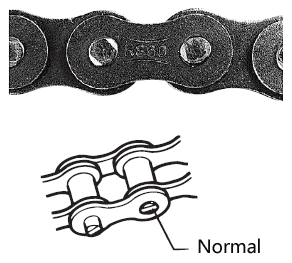

| 13 |

[Click to enlarge] |

Pin rotation or jumping out |

|---|

| Cause 1 | Overloaded or under-lubricated | Solution | Replace with a new one. Check for overload or improve oil supply. |

|---|---|---|---|

| Cause 2 | When the chain is under high load and the lubrication is insufficient, an abnormal friction force occurs between the pin and bushing, which can cause the pin to turn instantly. If the chain is operated under this condition, the pin will come out and the chain will be destroyed. | Solution | Immediately replace with a new one. Do not weld the pin or reuse the old pin. (Discard the old chain to avoid accidentally reusing it.) Also, if the pin head or plate side is worn, check the installation condition. |

Bush and roller related

| 14 | Roller bushing cracks (falls off) |

|---|

| Cause 1 | Improper lubrication | Solution | Apply oil appropriately to the conditions of use. Replace with new oil. |

|---|

| 15 | The roller does not rotate, or one side of the roller is worn |

|---|

| Cause 1 | RS25、RS35 | Solution | bushed chain and has no rollers. |

|---|---|---|---|

| Cause 2 | The inner plate is leaning inward or the bushing is cracked | Solution | Replace with a new one. Re-inspect the installation and check the load. |

| Cause 3 | Transported material or foreign matter gets between the bush and roller. | Solution | Clean it regularly. Install a casing to protect the chain. |

| Cause 4 | Roller load is excessive | Solution | Reduce the load or increase the size of the chain. |

| Cause 5 | Transported materials and foreign matter accumulate on the frame | Solution | Remove regularly and install a partition to protect the chain. |

| Cause 6 | Rusted bushes and rollers | Solution | Reselection of appropriate specifications (materials) |

| Cause 7 | The inner plate moves inward | Solution | Replacement, installation re-inspection, load re-inspection |

| 16 | The roller opens |

|---|

| Cause 1 |

overload |

Solution | Reduce the load. Properly lubricate. |

|---|

| 17 | The roller becomes drum-shaped |

|---|

| Cause 1 | Overload or insufficient oil | Solution | Replace with a new one. Check for overload or improve oil supply. |

|---|